Combined type composite material bearing support

A composite material and combined technology, applied in the direction of pipeline supports, mechanical equipment, pipes/pipe joints/fittings, etc., can solve the problems of poor long-term weather resistance, unsatisfactory effects, low mechanical properties of products, etc., and achieve anti-aging Excellent performance, high construction efficiency, strong designability and machinability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] Preparation of uprights and support arms:

[0043] Both the column and the support arm are made of thermosetting resin and continuous fiber through pultrusion process.

[0044] The volume content of the continuous fiber in the column and the supporting arm is 50%-85%.

[0045] Thermoset resins include polyurethane, epoxy, phenolic, vinyl, or unsaturated polyester resins; continuous fibers include glass, carbon, aramid, basalt, or hybrid fibers; continuous fibers can be in the form of continuous fiber yarn , felt, cloth or tape.

Embodiment 1

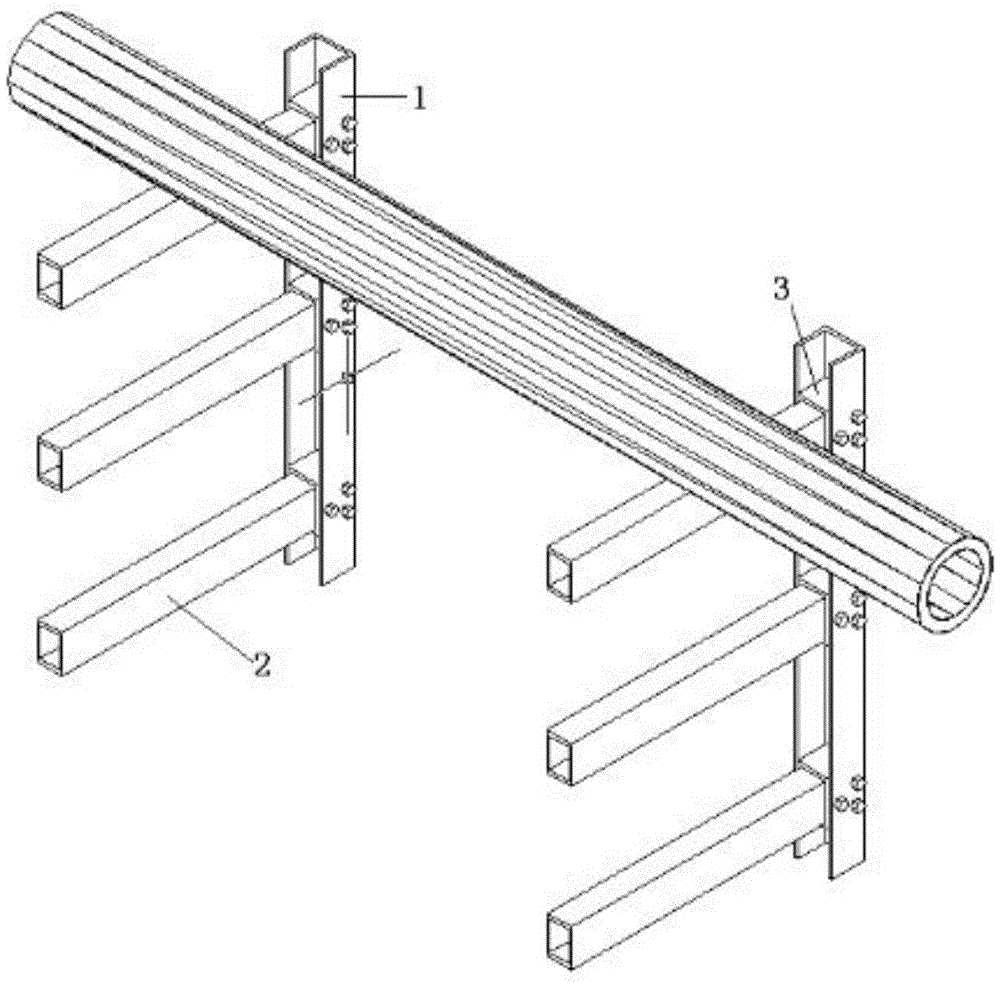

[0047] A combined composite load-bearing bracket, including a column, a connecting piece and a support arm, the support arm is vertically connected to the column through the connecting piece;

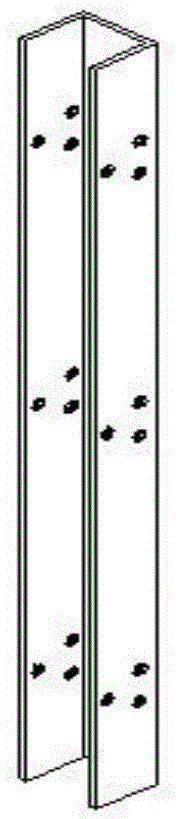

[0048] Both the column and the support arm are straight column type; the cross section of the column is U-shaped, the wall thickness is 0.8cm, the cross section of the support arm is rectangular, and the wall thickness is 0.5cm;

[0049]The connector is a reinforced sleeve, the cross section of the column is a U-shaped groove structure, the reinforced sleeve is a ring structure, one end of the support arm is sleeved with the reinforced sleeve and placed in the groove of the column; the support arm It is fixed on the column by the bolts that pass through the column, the reinforcing sleeve and the supporting arm; the reinforcing sleeve and the supporting arm are tightly fitted, and the reinforcing sleeve and the column are tightly fitted;

[0050] When in use, the heavy object is installe...

Embodiment 2

[0057] It is basically the same as Embodiment 1, except that the cross-section of the column and the support arm is C-shaped, the groove width is 5cm, and the wall thickness is 1cm; the connector is a reinforced connector, and the reinforced connector includes a There are two connecting plates on both sides of the connection between the column and the support arm, and the support arm is fixed on the column by the bolts passing through the two connecting plates and the column and the bolts passing through the two connecting plates and the support arm;

[0058] One side of the L-shaped connecting plate is fixed on the surface of the connecting plate through the bolts passing through the two connecting plates and the column, and the other side of the connecting plate is anchored to the building. One side and the other side of the connecting plate refer to the two outer sides perpendicular to each other. ;

[0059] Preparation of columns and brackets (fiber volume content 85%):

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com