Locking structure of automobile seat sliding rail

A technology of a car seat slide rail and locking structure, which is applied in directions such as movable seats, can solve the problems of high cost and large space occupied by the locking mechanism, and achieve the effects of improving longitudinal strength, increasing space utilization, and reducing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

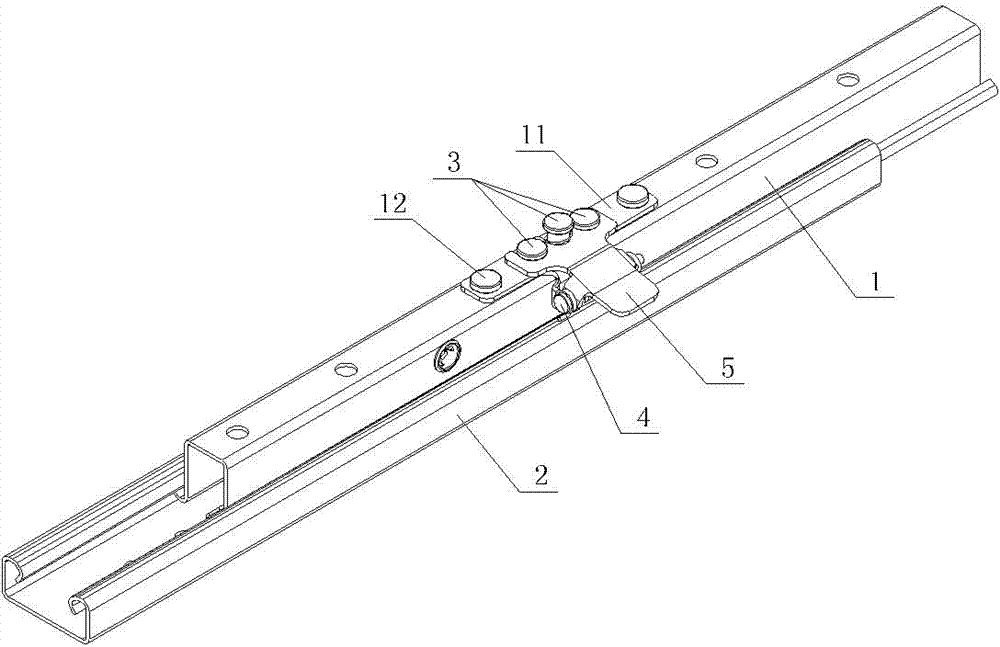

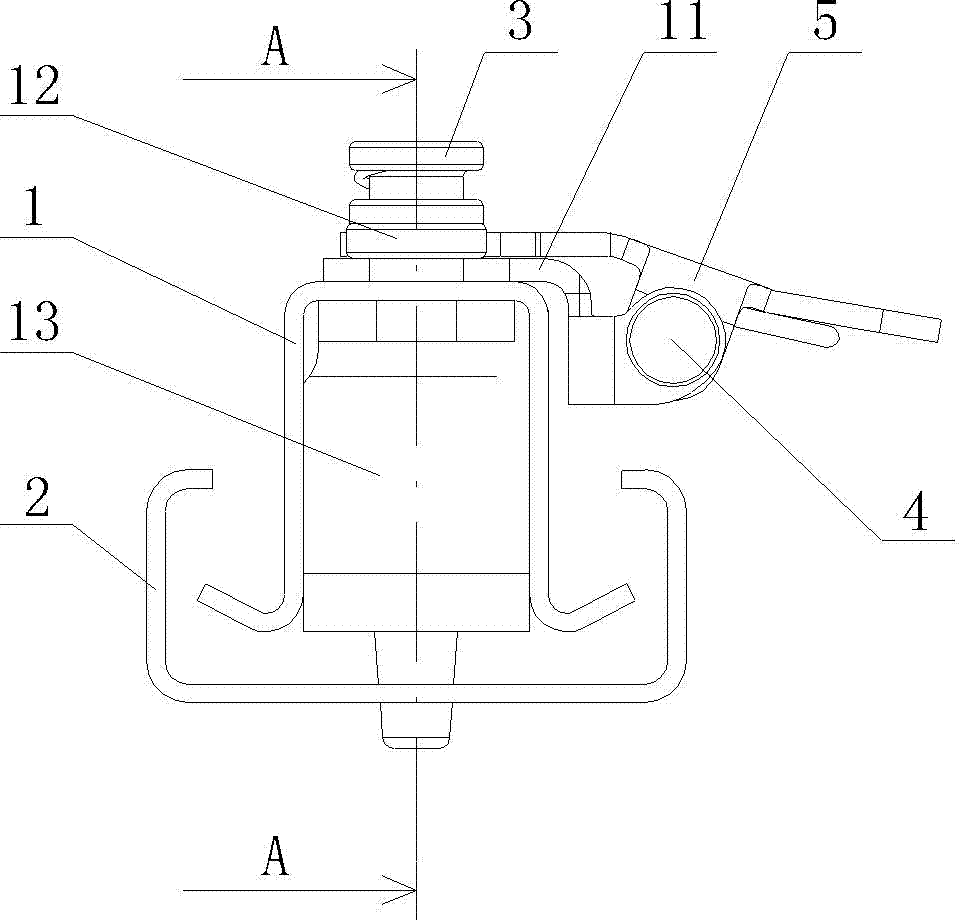

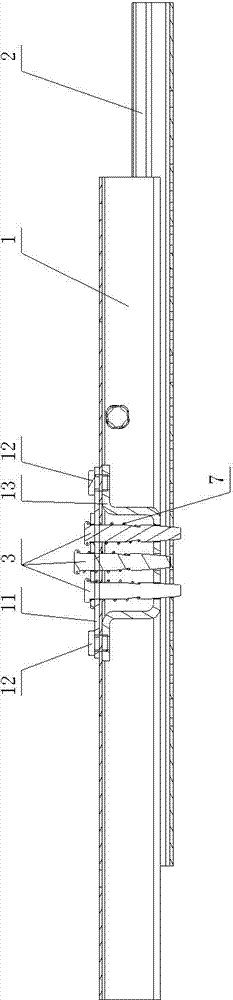

[0013] See Figure 4 , Figure 5 with Image 6 , the present invention includes an upper slide rail 1, a lower slide rail 2, a locking pin 3, a shaft pin 4 and an unlocking drive plate 5, the upper slide rail 1 is installed in the lower slide rail 2, and the upper slide rail 1 can The lower rail 2 moves back and forth horizontally, the lower rail 2 has a locking hole (not shown in the figure), the upper rail 1 is installed with a pin mounting bracket 6, and the locking pin 3 passes through the upper slide from top to bottom Rail 1, column pin mounting bracket 6, locking column pin 3 is connected and installed with column pin return spring 7, unlocking drive plate 5 is installed on shaft pin 4 through unlocking and driving return spring 8, and shaft pin 4 is installed on the upper side through support plate 9 On the slide rail 1 , the front bayonet of the unlocking drive plate 5 is engaged with the locking pin, and the support plate 9 is fixedly mounted on one side of the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com