Special patterned tire for high-speed car

A kind of pattern and automobile technology, applied in the direction of tire parts, tire tread/tread pattern, vehicle parts, etc., to achieve the effect of excellent function, good safety and wide application environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

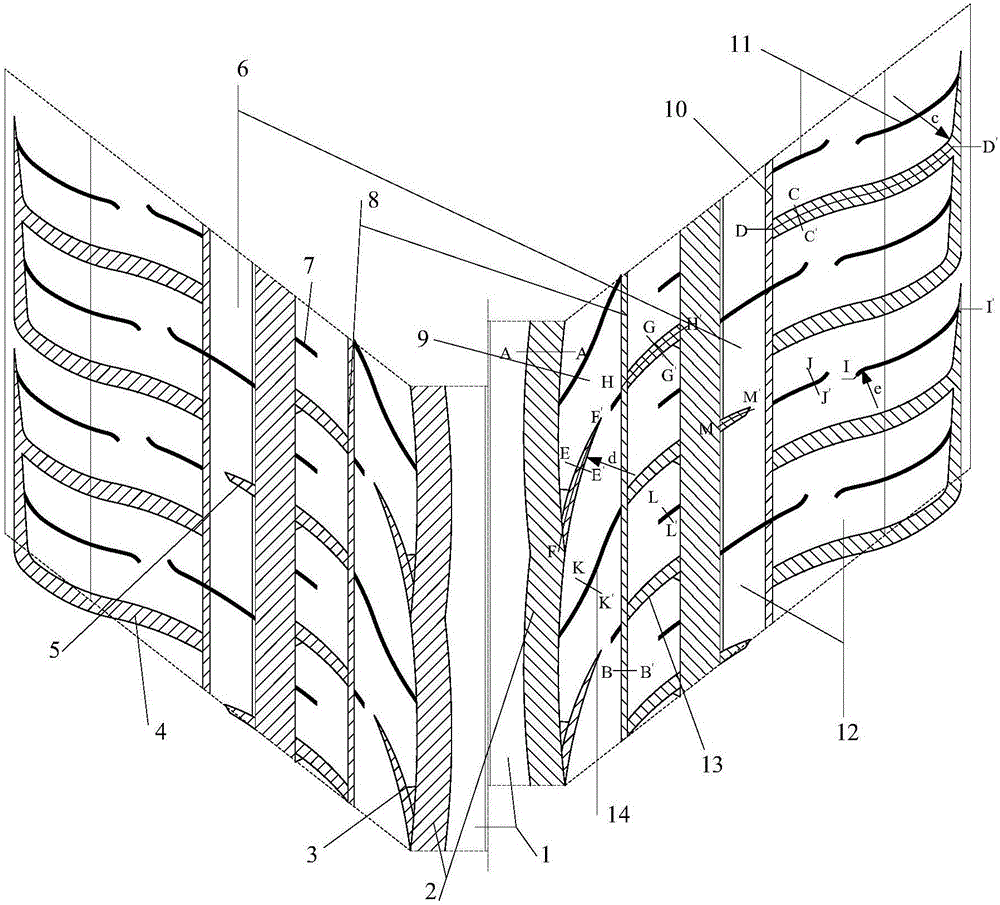

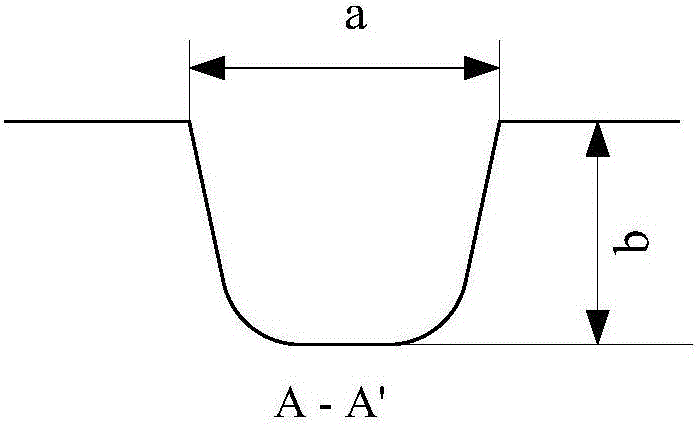

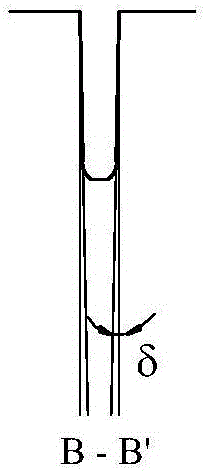

[0038]The main structure of the patterned tire for high-speed vehicles involved in this embodiment consists of central ribs 1, main drainage grooves 2, 3D grooves 3, oblique pattern grooves 4, small transverse grooves 5, side drainage grooves 6, and small fine sipes. 7. The main small groove 8, the continuous block type bionic pattern block 9, the side small groove 10, the S-shaped sipe 11, the closed outer tire shoulder 12, the large transverse groove 13 and the water-like sipe 14; the tread is composed of The central rib 1 is divided into the left pattern and the right pattern as the dividing line. The left pattern and the right pattern have the same shape and are arranged in a mirror image, which can effectively reduce noise and prevent abnormal wear of the tire; the width of the central rib 1 is 40~ 55mm, to ensure the best rigidity of the tire, so that the steering force of the tire is directly transferred from the tire to the road surface; two main drains 2 are distribute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com