Unmanned aerial vehicle body integrated molding technology

A molding process and UAV technology, which is applied in the direction of fuselage, fuselage frame, aircraft assembly, etc., can solve the problems that the drone fuselage does not adopt the integrated molding process and the difference in the mechanical properties of the fuselage, and achieve easy daily Maintenance, short molding time, and improved overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

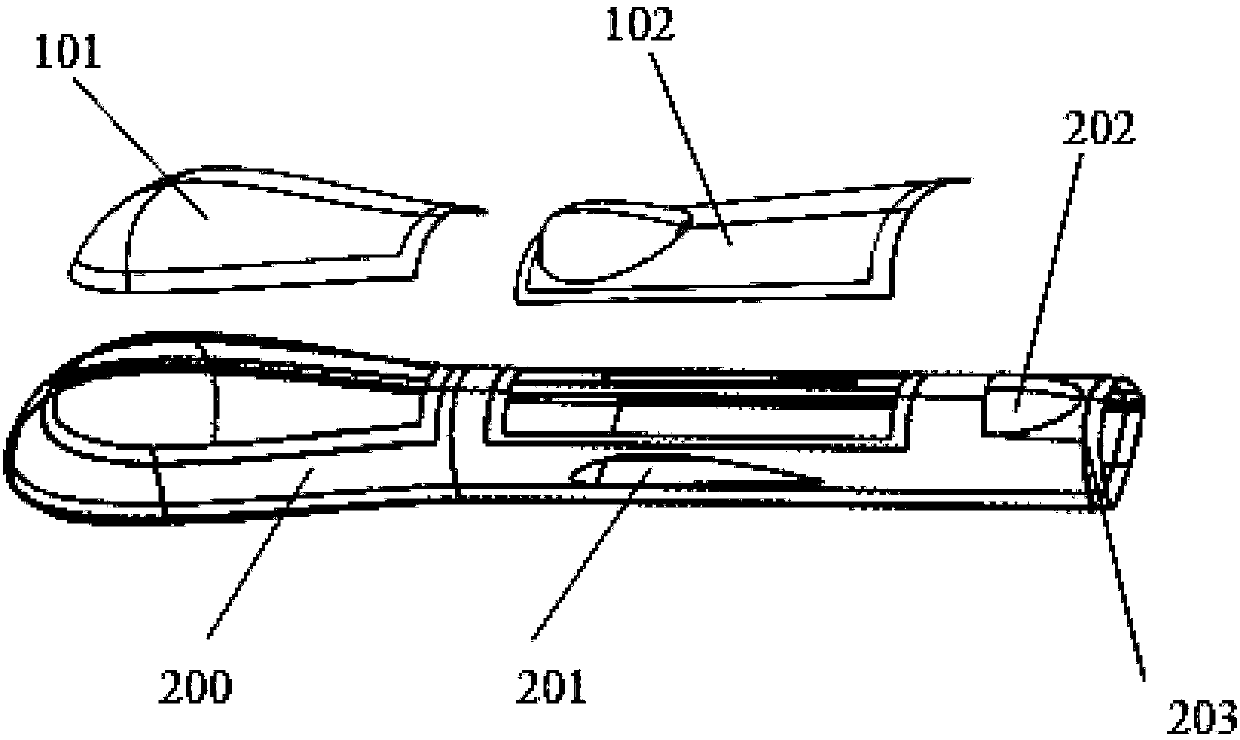

[0043] figure 1The carbon fiber composite unmanned aerial vehicle fuselage prepared for the present invention includes a front cover 101, a rear cover 102 and a fuselage shell 200, and the fuselage shell 200 is provided with a wing opening 201, an air inlet 202 and a tail section 203. Using carbon fiber unidirectional prepreg, carbon fiber fabric prepreg and lightweight foam as raw materials, the prepreg 2 is laid on the inner surface of the mold 1 by lap joint overall lay-up technology, and finally the autoclave molding technology is used to manufacture Obtained carbon fiber composite drone fuselage.

[0044] In this example:

[0045] Carbon fiber unidirectional prepreg: Jiangsu Hengshen / EM101-35%-A3-U-180gsm is used specifically, with a single layer thickness of 0.15mm. The carbon fiber unidirectional prepreg includes unidirectional carbon fiber, epoxy resin, and toughening agent equal components, the weight percentage of epoxy resin in the carbon fiber unidirectional prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com