Organic biological feedstuff additive containing nano-selenium, zinc oxide, preparation and use method thereof

A feed additive, nano-zinc oxide technology, applied in zinc compounds, inorganic nano-selenium, adding organic trace element food elements, milk, and producing eggs rich in organic trace elements, can solve the problem of low conversion rate of inorganic selenium, complex process, The problem of high cost, to achieve the effect of no environmental pollution problem, easy availability of raw materials, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

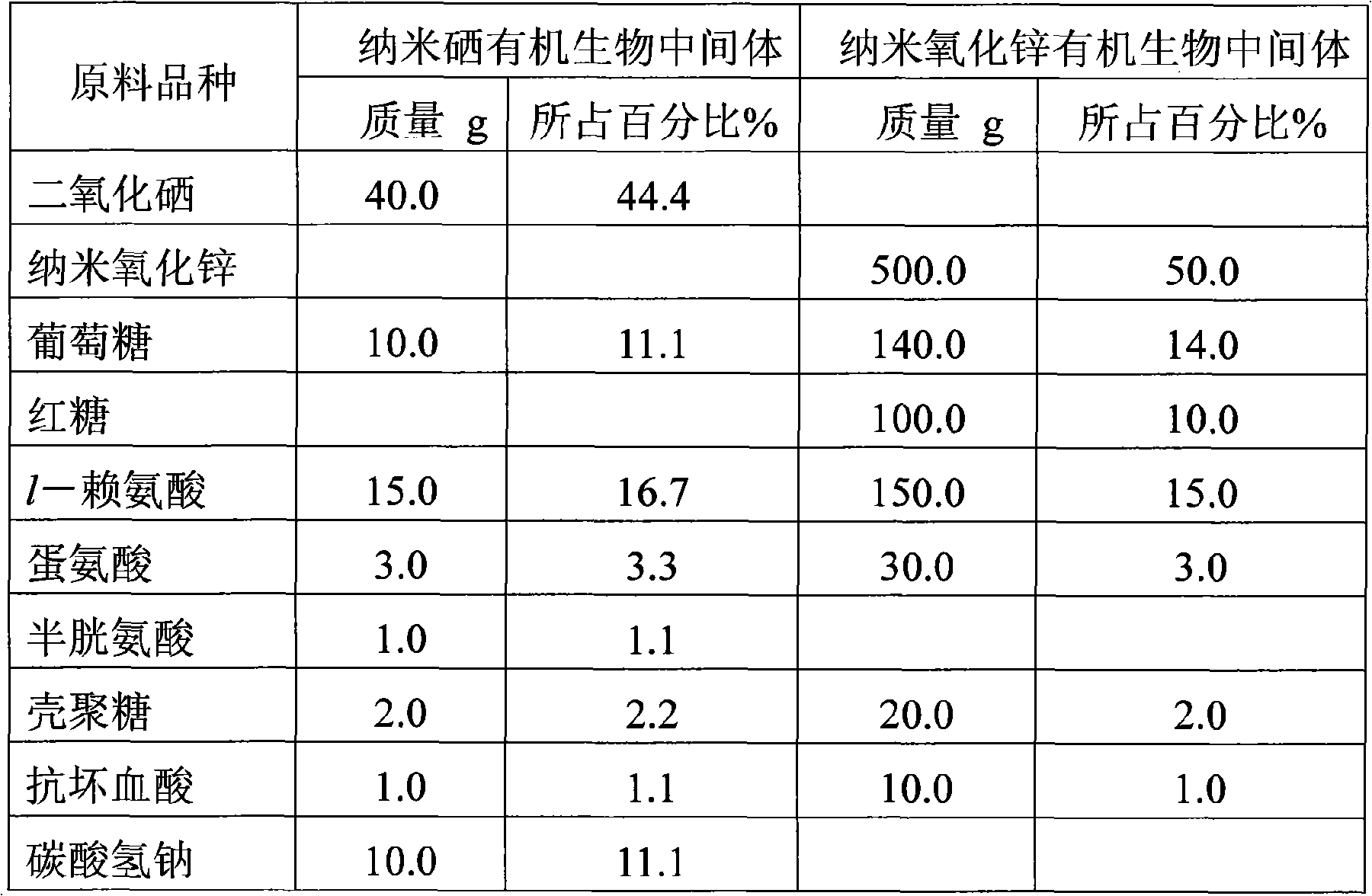

[0052] Preparation of nano selenium and zinc oxide organic biological feed additives containing 0.31% and 39.5% selenium and zinc respectively. The ratio and quality of raw materials used in its nano-selenium organic biological intermediate and nano-zinc oxide organic biological intermediate are as follows:

[0053]

[0054] (to be continued)

[0055] (Continued from table on previous page)

[0056]

[0057] Its preparation process is:

[0058] (1) Preparation of nano-selenium organic biological intermediate: Selenium dioxide, glucose, l-lysine, methionine, cysteine, chitosan, ascorbic acid are placed in a grinder and mixed Grind for 30 minutes, let stand for 24 hours, then mix with sodium bicarbonate, potassium dihydrogen phosphate, manganese sulfate monohydrate, magnesium sulfate heptahydrate, calcium chloride anhydrous, ferrous sulfate heptahydrate, add water, honey, EM original dew and stir evenly After sealing, it reacts for 10 days under the condition of light a...

Embodiment 2

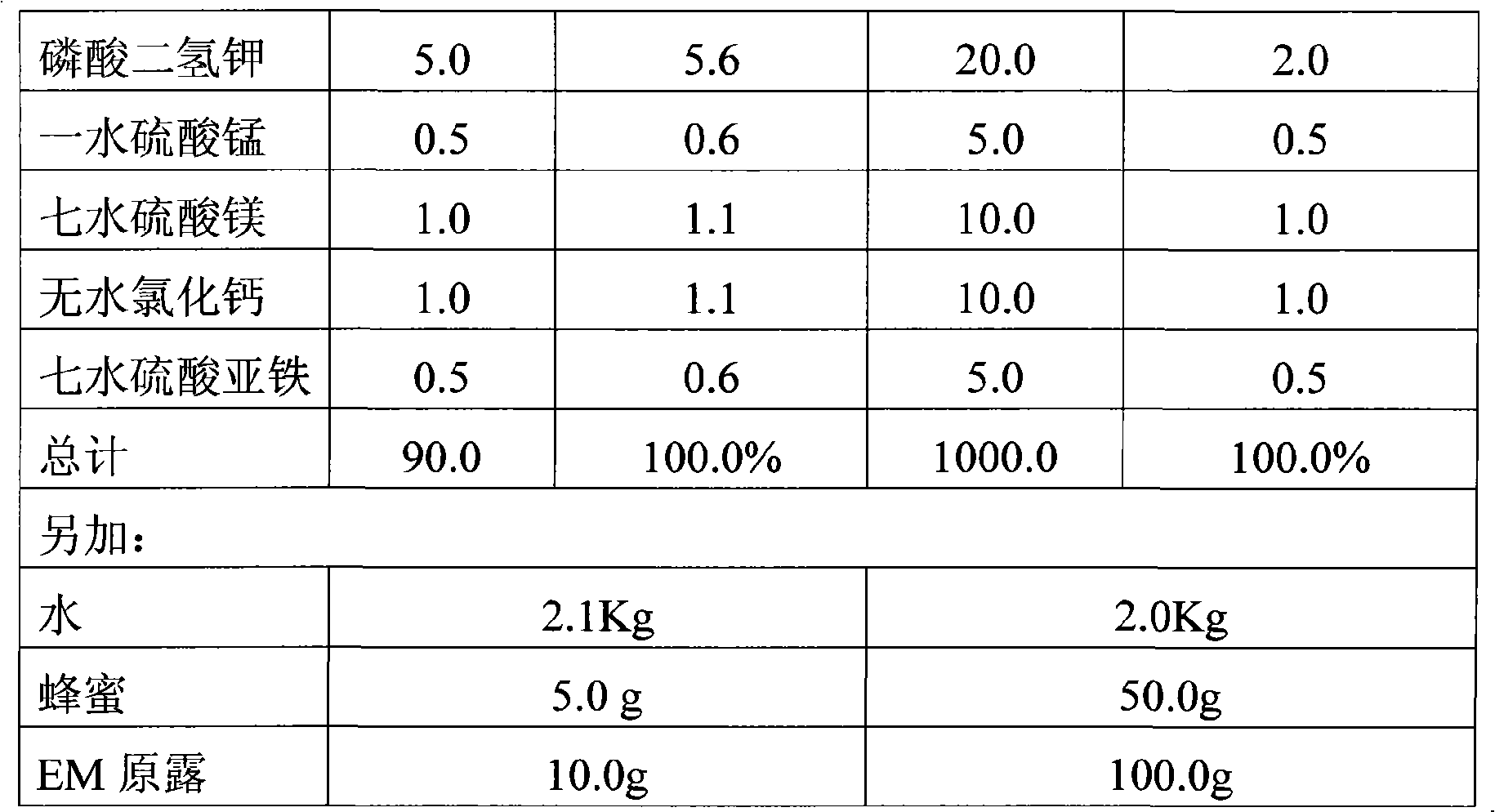

[0065] Preparation of nano-selenium and zinc oxide organic biological feed additives containing 0.28% and 35.75% of selenium and zinc respectively. The ratio and quality of raw materials used in its nano-selenium organic biological intermediate and nano-zinc oxide organic biological intermediate are as follows:

[0066]

[0067] (to be continued)

[0068] (Continued from table on previous page)

[0069]

[0070] The nano-selenium, zinc oxide organic biological feed additive dry powder prepared by the same method as in Example 1 has a selenium content and a zinc content of 0.28% and 35.75% respectively. Prepare the water preparation that obtains with the same method of embodiment 1, add feed, feed same number of laying hens, dairy cows and milk sheep, and the selenium content of obtained eggs, milk and sheep milk is respectively 0.357mg / Kg, 0.018mg / Kg and 0.020mg / Kg, which are 3.5 times, 3.6 times and 4.6 times of the control sample; the zinc content is 16.4mg / Kg, 3.0mg...

Embodiment 3

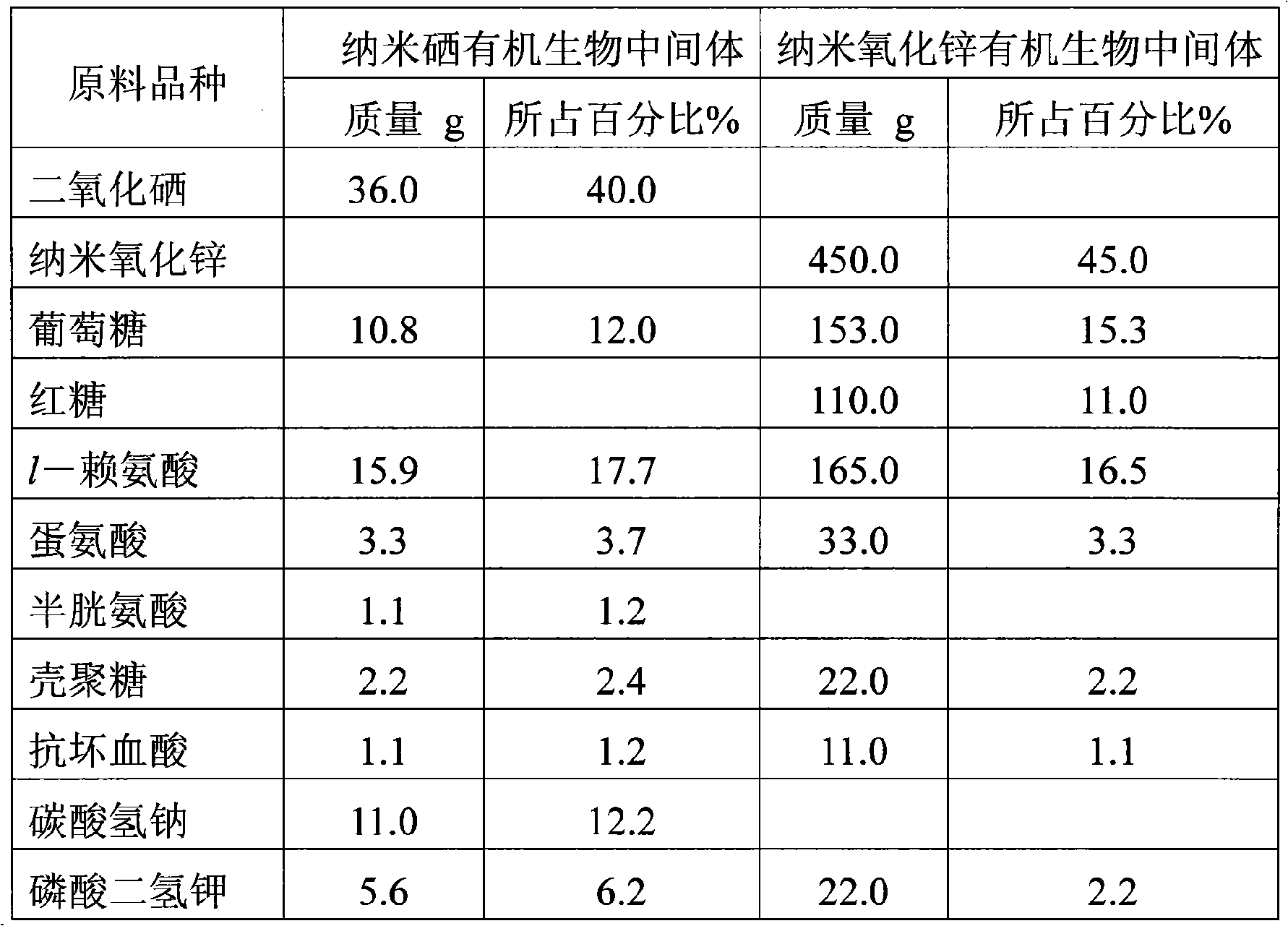

[0072] Preparation of nano-selenium and zinc oxide organic biological feed additives containing 0.35% and 43.80% of selenium and zinc respectively. The ratio and quality of raw materials used in its nano-selenium organic biological intermediate and nano-zinc oxide organic biological intermediate are as follows:

[0073]

[0074] (to be continued)

[0075] (Continued from table on previous page)

[0076]

[0077] The nano-selenium, zinc oxide organic biological feed additive dry powder prepared by the same method as in Example 1 has a selenium content and a zinc content of 0.35% and 43.80% respectively. Prepare the liquid that obtains with the same method of embodiment 1, add feed, feed same number of laying hens, dairy cows and dairy sheep, and the selenium content of obtained eggs, milk and goat milk is respectively 0.485mg / Kg, 0.024mg / Kg and 0.028mg / Kg, which are 4.6 times, 4.8 times and 5.6 times of the control sample; the zinc content is 20.2mg / Kg, 3.8mg / Kg and 4.2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com