Method for co-production of oligose and dietary fiber through wheat bran fermentation

A technology of dietary fiber and oligosaccharides, which is applied in the field of co-production of oligosaccharides and dietary fibers from fermented wheat bran, can solve problems such as environmental pollution and waste of resources, and achieve the effects of no environmental pollution, low production costs, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

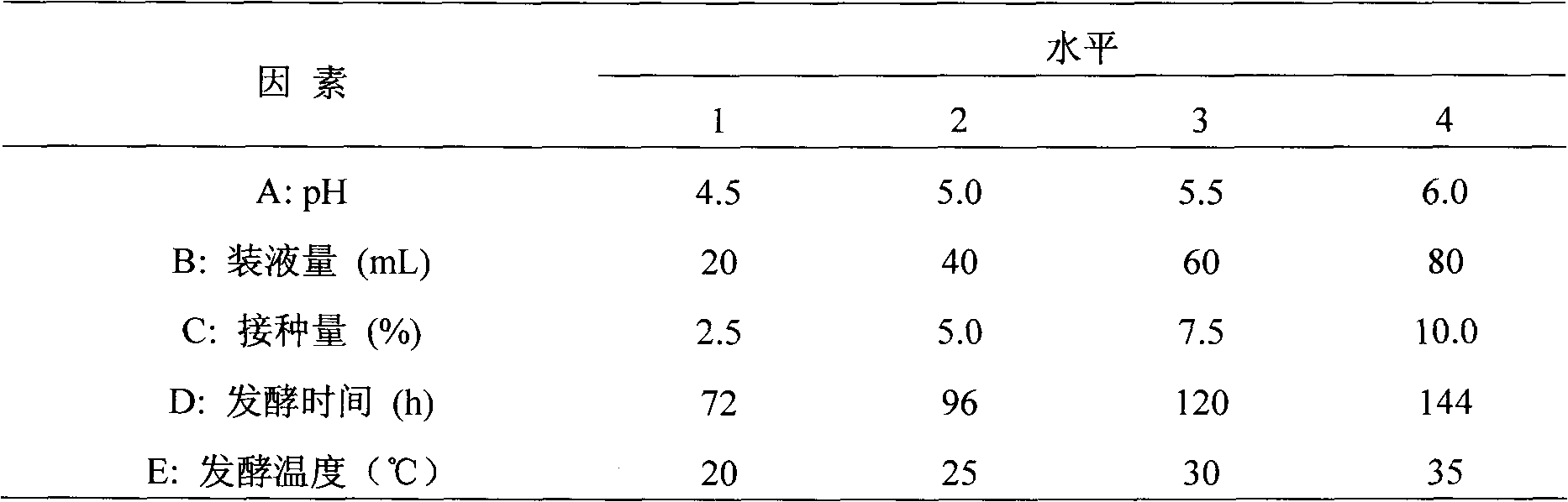

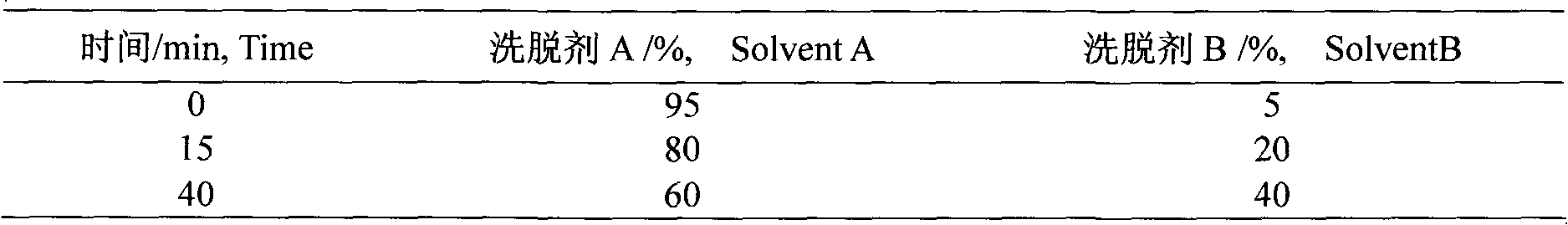

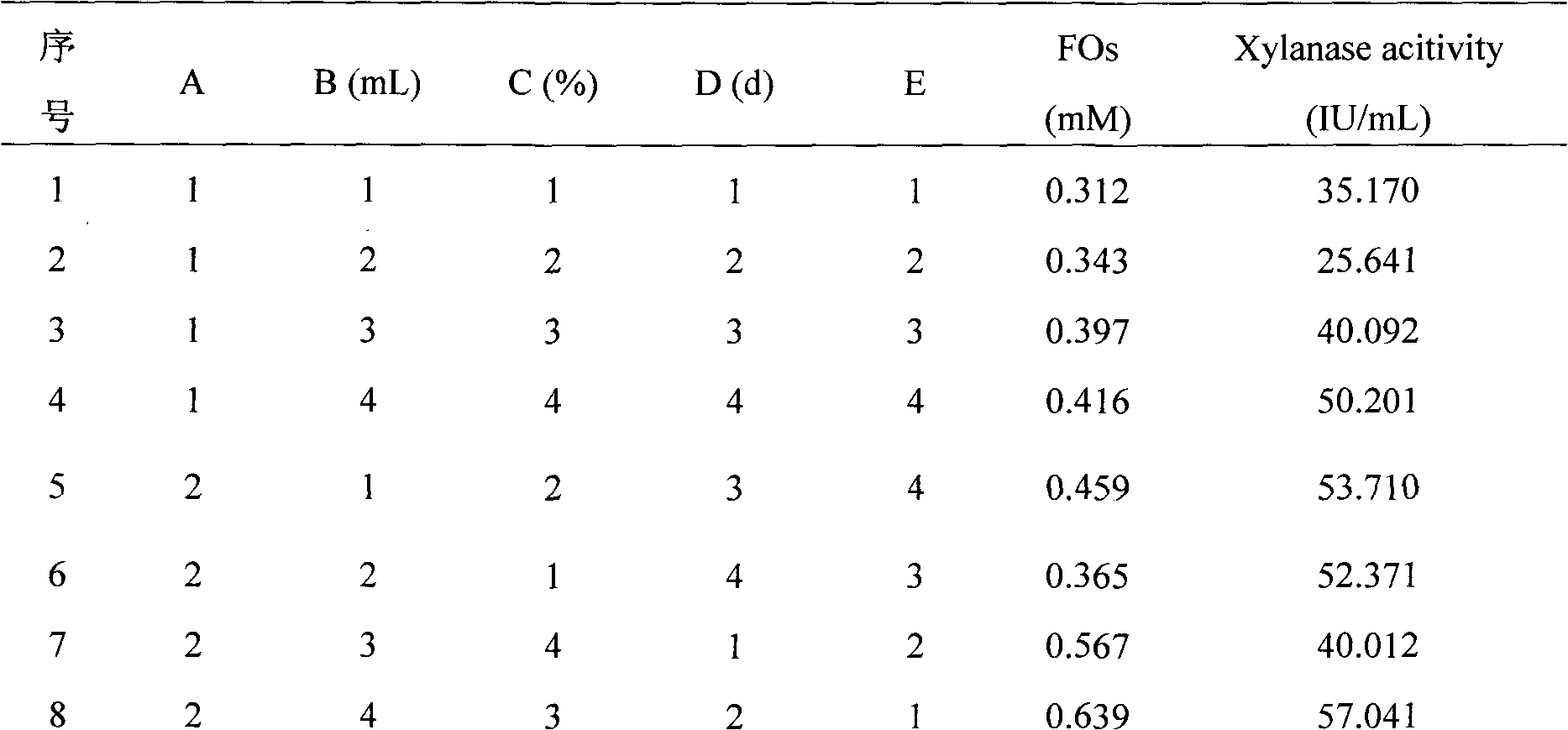

[0013] Embodiment 1 Aureobasidium pullulans produces feruloyl oligosaccharides fermentation process optimization

[0014] 1. Preparation of culture medium

[0015] Strain activation medium (g / L): potato 200 sucrose 20 peptone 5 agar powder 20pH natural distilled water 1000mL 0.103MPa sterilized for 20min;

[0016] Seed medium (g / L): sucrose 50Na 2 HPO 4 5.0 yeast extract 3.0 MgS04 7H 2 O 0.2 (NH 4 ) 2 SO 4 0.6NaCl0.1 pH6.0 distilled water 1000mL 0.103MPa sterilization for 20min;

[0017] Fermentation medium (g / L): wheat bran liquid 20KH 2 PO 4 1 MgSO 4 ·7H 2 O 1 V B1 0.1 0.103MPa sterilization for 20min.

[0018] 2. Strain culture

[0019] Cultivation of mother species: at a temperature of 28°C, a shaker speed of 180r / min, and a liquid volume of 50mL / 250mL in a conical flask, inoculate a block of mother species with a diameter of about 4mm, and cultivate for 3 days;

[0020] Fermentation conditions for determining culture conditions: Based on the previous sin...

Embodiment 2

[0045] The orthogonal test of embodiment 2 mixed bacteria fermentation production xylanase

[0046] Select the four factors of wheat bran particle size, wheat bran treatment method, wheat bran water content, and bacterial strain combination method, and use the orthogonal test table to carry out four-factor three-level orthogonal experiments (Table 5), and optimize the production of xylanase. The best mixed culture combination.

[0047] Table 5 Orthogonal experiment factors and levels

[0048] Table 5 Factors and levels in orthogonal experiment

[0049]

[0050] Table 6 Orthogonal experimental design

[0051] Table 6 Orthogonal experimental design

[0052]

[0053] It can be seen from Table 6 that the effect of xylanase produced by solid-state fermentation of mixed bacteria on wheat bran is as follows: In the single factor test of medium, the degree of influence is in the order of wheat bran treatment method>bacteria combination method>wheat bran particle size>wheat br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com