Preparation method of ultralow-viscosity sodium carboxymethyl cellulose

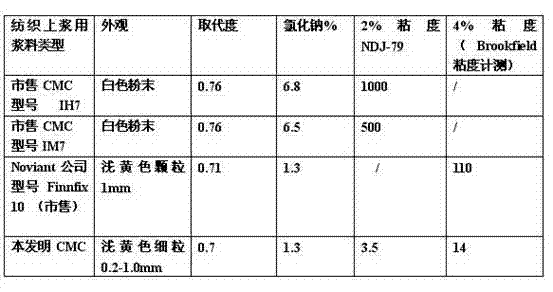

A technology of sodium carboxymethyl cellulose and viscosity, which is applied in fiber treatment, textiles and papermaking, etc., can solve the problem of high viscosity of sodium carboxymethyl cellulose, and achieve good water solubility, stable viscosity and good film-forming properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Add 1kg of cotton fiber that has been loosened, 1.45kg of 48% sodium hydroxide and 1.5kg of 90% ethanol to the kneader at the same time, then add 0.06kg of solid sodium perborate powder and 0.18kg of 30% hydrogen peroxide ethanol solution (ethanol accounts for 70%), add in 3 times, under stirring, heat up to 60°C, reduce viscosity for 60 minutes. Spray 0.9kg of ethanol solution of chloroacetic acid (the concentration of chloroacetic acid is 50%) into the kneader evenly, carry out carboxymethylation reaction, react at 76°C for 50 minutes, then cool down to 60°C, and then continue to add 50% 0.10kg of hydrogen peroxide ethanol solution, reduce viscosity for 60 minutes, add 0.7% (based on cotton fiber quality) sodium sulfite, react for 10 minutes, cool down and discharge, neutralize, wash, centrifuge, dry, and pulverize to obtain pure low-viscosity carboxymethyl Sodium cellulose. Substitution degree 0.84, type B (Brookfield) 4% viscosity 8.8cps, purity 97.7%, cmc solution...

Embodiment 2

[0026] Put 1kg of cotton fiber that has been opened, 1.35kg of 49% sodium hydroxide aqueous solution and 1.5kg of 90% ethanol into the kneader at the same time, and then add 0.20kg of 27% hydrogen peroxide ethanol solution (73% ethanol), divide into 3 Add it once, stir and heat up to 50°C, and reduce the viscosity for 60 minutes. Spray 0.75kg of ethanol solution of chloroacetic acid (the concentration of chloroacetic acid is 80%) evenly into the kneader for carboxymethylation reaction, react at 77°C for 40 minutes, then cool down to 50°C, and then continue to add 70% Hydrogen peroxide ethanol solution 0.08kg, reduce viscosity for 50 minutes, add 0.6% sodium sulfite powder (based on cotton fiber quality), react for 10 minutes, then neutralize, wash, centrifuge, dry, and pulverize to obtain pure low-viscosity carboxymethyl The degree of substitution of sodium cellulose is 0.75. Type B (Brookfield Viscosity) has a 4% viscosity of 12cps, a purity of 98.1%, and a clear cmc solutio...

Embodiment 3

[0028] Put 1kg of cotton fiber that has been loosened, 1.25kg of 47% sodium hydroxide aqueous solution and 1.5kg of 90% ethanol into the kneader at the same time, and then add 0.16kg of 50% hydrogen peroxide ethanol solution (50% of ethanol), divide into 3 Add it once, stir and heat up to 60°C, and reduce the viscosity for 40 minutes. Spray 0.65kg of ethanol solution of chloroacetic acid (60% concentration of chloroacetic acid) evenly into the kneader for carboxymethylation reaction, react at 78°C for 60 minutes, then cool down to 60°C, and then continue to add 68% Hydrogen peroxide ethanol solution 0.08kg, reduce viscosity for 60 minutes, add 0.6% sodium sulfite powder (based on cotton fiber quality), react for 10 minutes, then neutralize, wash, centrifuge, dry, and pulverize to obtain pure low-viscosity carboxymethyl The degree of substitution of sodium cellulose is 0.68. Type B (Brookfield Viscosity) has a 4% viscosity of 17cps, a purity of 97.6%, and a clear cmc solution....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com