Adhesive gum special for sheet metal and preparation thereof

A metal sheet and adhesive technology, applied in the field of adhesives, can solve the problems of insufficient bonding between the colloid and the metal plate, weak peeling resistance, and unenvironmental protection, so as to achieve outstanding shock absorption and sound absorption effects, and reduce adhesive bonding. Destruction, performance-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

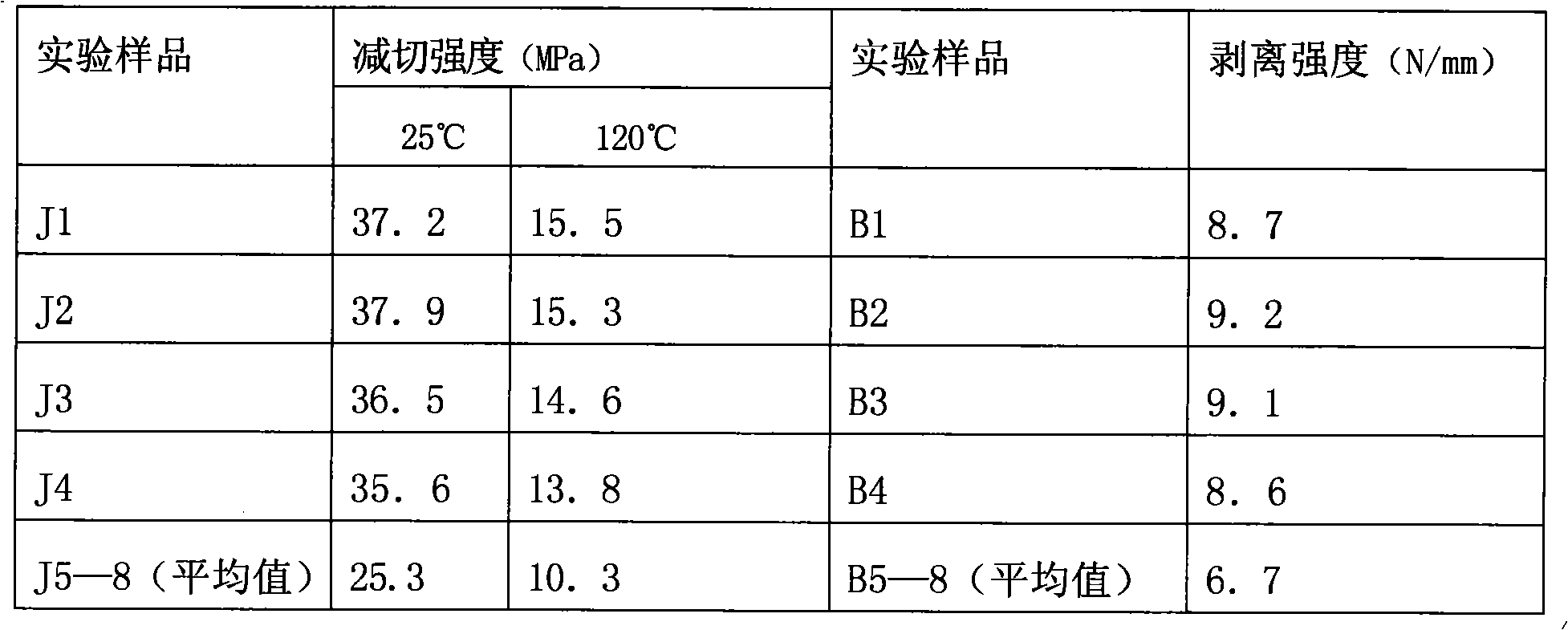

Embodiment 1

[0021] Example 1: Dissolve 2 parts (each weight is 50g, the same below) of γ-aminopropyltriethoxysilane in ethyl acetate at a ratio of 1:5, and mix 5 parts of nanometer Silica powder and 5 parts of nano-alumina powder were added to the above-mentioned silane coupling agent solution, treated with ultrasonic waves for 30 minutes, then distilled under reduced pressure to remove ethyl acetate, and dried to obtain active filler powder; the temperature was controlled at At 90°C, pour the active filler powder and 50 parts of epoxy resin into the reaction kettle of the vacuum disperser, and stir at a high speed of 1350rpm for 20 minutes to obtain a mixture of epoxy resin-active filler; then mix 100 parts of epoxy resin according to the proportion Pour one part of amino-terminated liquid nitrile rubber (with acrylonitrile content of 18) and 50 parts of ethyl acetate into the reaction kettle of the vacuum disperser, stir at a low speed of 350 rpm for 35 minutes, then control the temperat...

Embodiment 2

[0022] Example 2: Dissolve 1 part (each weight is 50g, the same below) of γ-aminopropyltriethoxysilane in ethyl acetate at a ratio of 1:5, and mix 7 parts of nanometer Silica powder and 6 parts of nano-alumina powder are added to the above-mentioned silane coupling agent solution, treated with ultrasonic waves for 30 minutes, then the ethyl acetate is removed by distillation under reduced pressure, and dried to obtain the active filler powder; the temperature is controlled at At 90°C, pour the active filler powder and 40 parts of epoxy resin into the reaction kettle of the vacuum disperser, and stir at a high speed of 1350rpm for 20 minutes to form the mixture of epoxy resin-active filler; then mix 90 parts of epoxy resin according to the proportion Pour amino-terminated liquid nitrile rubber (acrylonitrile content: 26%) and 55 parts of ethyl acetate into the reaction kettle of the vacuum disperser, stir at a low speed of 350 rpm for 35 minutes, then control the temperature at ...

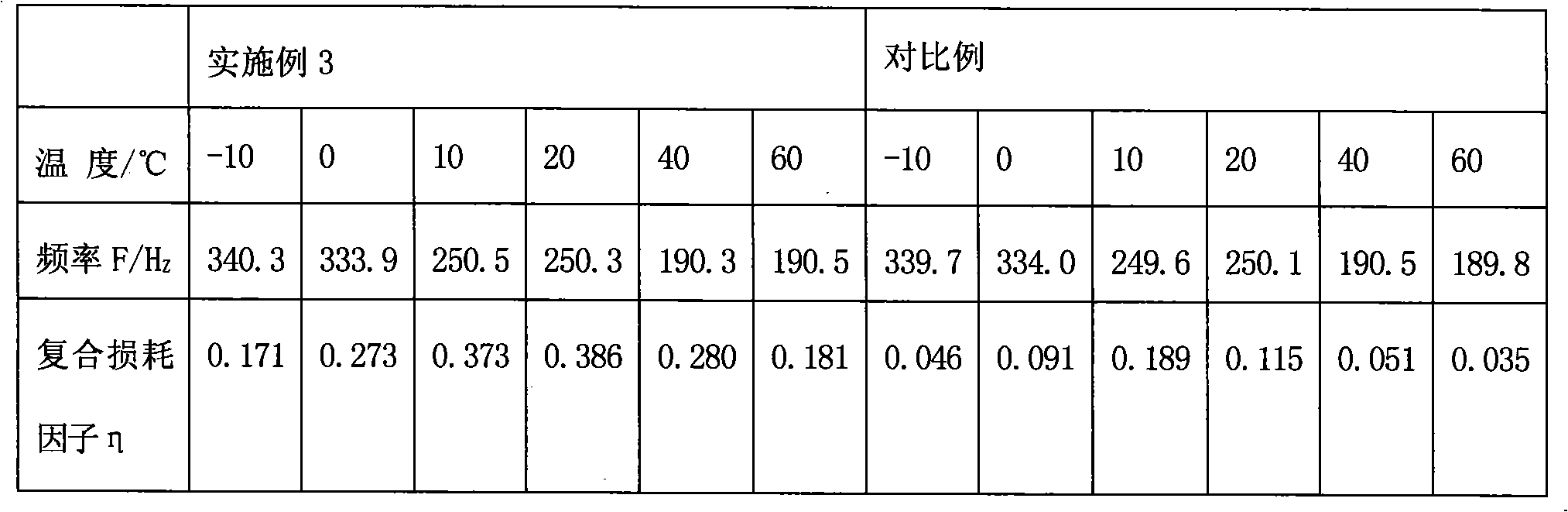

Embodiment 3

[0023] Example 3: Dissolve 2 parts (each weight is 50g, the same below) of γ-aminopropyltriethoxysilane in ethyl acetate at a ratio of 1:5, and mix 6 parts of nanometer Silicon oxide powder and 7 parts of nano-alumina powder were added to the above-mentioned silane coupling agent solution, treated with ultrasonic waves for 30 minutes, then distilled under reduced pressure to remove ethyl acetate, and dried to obtain active filler powder; the temperature was controlled at At 90°C, pour the active filler powder and 45 parts of epoxy resin into the reaction kettle of the vacuum disperser, and stir at a high speed of 1350rpm for 20 minutes to obtain a mixture of epoxy resin-active filler; then mix 95 parts of epoxy resin according to the proportion Pour 60 parts of amino-terminated liquid nitrile rubber (acrylonitrile content is 18) and 60 parts of ethyl acetate into the reaction kettle of the vacuum disperser, stir at a low speed for 35 minutes at a speed of 350 rpm, then control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com