Process for preparing furan through decarbonylation of furfural

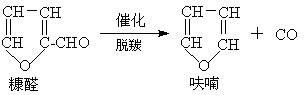

A technology for decarbonylation to furan and furfural purification, which can be used in metal/metal oxide/metal hydroxide catalysts, organic chemistry, physical/chemical process catalysts, etc., and can solve the problems of low yield and pollution, low furan selectivity, etc. , to achieve the effect of high purity, high yield and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

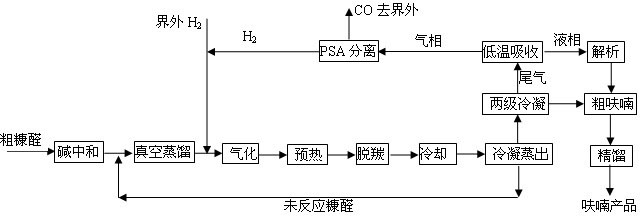

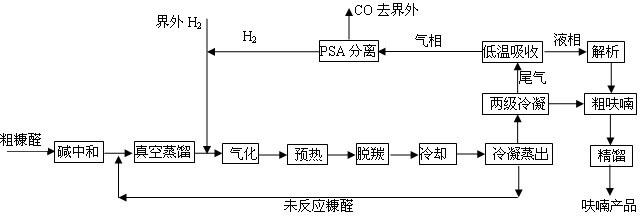

[0035] Embodiment 1: as figure 1 Shown, a kind of furfural decarbonylation furan process comprises the following steps:

[0036] A. Furfural refining: 100L crude furfural raw material is neutralized by 1% NaOH solution and then sent to furfural refining tower, where the furfural self-polymer is removed by vacuum distillation at an absolute pressure of 5KPa and 70-80°C;

[0037] B. Furfural gasification: send the refined furfural obtained in step A into the furfural intermediate tank, and send it to the vaporizer for gasification according to the molar ratio of 1:1 with hydrogen. The gasification temperature is 180°C and normal pressure;

[0038] C. Decarbonylation: send the gaseous mixture obtained in step B into a preheater to preheat to 250°C, and send the preheated gas into a decarbonylation reactor at a temperature of 250°C, and the volume space velocity of furfural liquid is 1h -1 , the catalytic decarbonylation reaction is carried out under normal pressure, and the cata...

Embodiment 2

[0042] Embodiment 2: as figure 1 Shown, a kind of furfural decarbonylation furan process comprises the following steps:

[0043] A. Furfural refining: 200L of crude furfural as raw material is neutralized by 2% KOH solution, then pumped into the furfural refining tower by a metering pump, and the furfural self-polymer is removed by vacuum distillation at an absolute pressure of 30KPa and 115-125°C;

[0044] B. Furfural gasification: send the refined furfural obtained in step A into the furfural intermediate tank, and send it to the vaporizer for gasification according to the molar ratio of 1:4 with hydrogen. The gasification temperature is 250°C and normal pressure;

[0045] C. Decarbonylation: send the gaseous mixture obtained in step B into a preheater to preheat to 350°C, and send the preheated gas into a decarbonylation reactor at a temperature of 350°C, and the volume space velocity of furfural liquid is 2h -1 , the catalytic decarbonylation reaction is carried out under...

Embodiment 3

[0049] Embodiment 3: as figure 1 Shown, a kind of furfural decarbonylation furan process comprises the following steps:

[0050] A. Furfural refining: 150L crude furfural as raw material is neutralized by 10% NaOH solution, then pumped into the furfural refining tower by metering pump, and the furfural self-polymer is removed by vacuum distillation at an absolute pressure of 15KPa and 97-107°C;

[0051] B. Furfural gasification: send the refined furfural obtained in step A into the furfural intermediate tank, and send it to the vaporizer for gasification according to the molar ratio of 1:0.5 with hydrogen. The gasification temperature is 220°C and normal pressure;

[0052] C. Decarbonylation: send the gaseous mixture obtained in step B into a preheater to preheat to 200°C, and send the preheated gas into a decarbonylation reactor at a temperature of 200°C, and the volume space velocity of furfural liquid is 0.5h -1 , under atmospheric pressure for catalytic decarbonylation re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com