Cleaning technology of generator rotor water cooling system

A generator rotor and water cooling system technology, applied in the field of cleaning technology, can solve problems such as energy loss, affecting cooling effect, and corrosion of hollow copper wires, so as to reduce operating temperature and temperature difference, improve wire heat exchange efficiency, and restore water flow capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

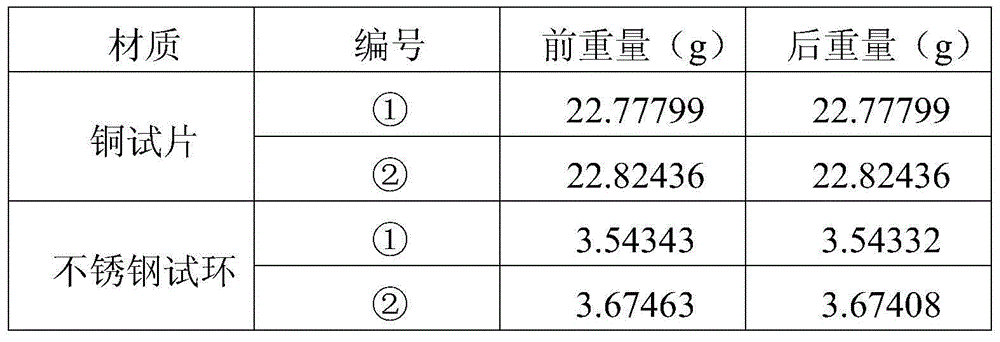

Embodiment 1

[0030] Take the coal-fired generator set QFS2-330-2 generator as an example:

[0031]Its cooling system is a double water cooling system, and the rotor winding of the double water internal cooling cooling method is water internal cooling. The factory test pressure of the internal cooling water system of the stator and rotor windings is 1MPa; the water pressure after installation is 0.75MPa.

[0032] 1.1 Cleaning process:

[0033] A cleaning process for the water-cooling system of the generator rotor. The water-cooling system of the generator rotor is cleaned in a forward and reverse cycle, and sequentially undergoes the washing process before preheating, system preheating, alkali washing, water washing after alkali washing, pre-slow release, pickling, The process of water washing after pickling, pre-filming, and water washing after pre-filming completes the cleaning of the water cooling system of the generator rotor.

[0034] Among them, the generator rotor water cooling sys...

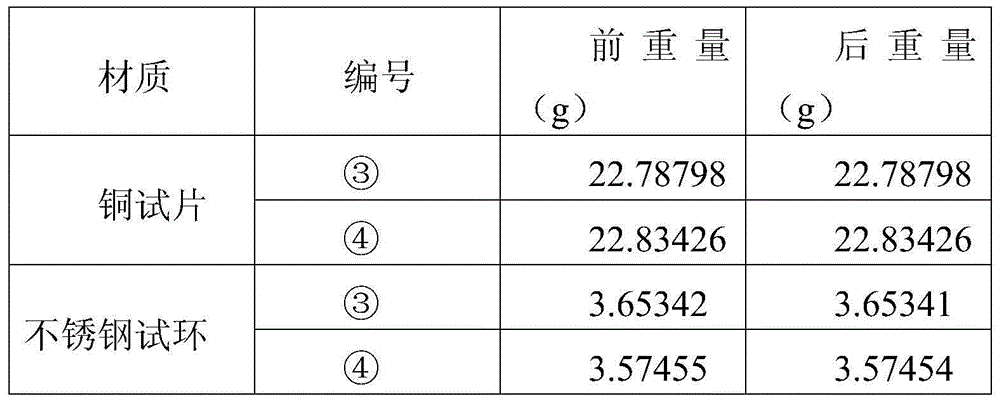

Embodiment 2

[0068] Take the coal-fired generator set QFS2-330-2 generator as an example:

[0069] Its cooling system is a double water cooling system, and the rotor winding of the double water internal cooling cooling method is water internal cooling. The factory test pressure of the internal cooling water system of the stator and rotor windings is 1MPa; the water pressure after installation is 0.75MPa.

[0070] 2.1 Cleaning process:

[0071] A cleaning process for the water-cooling system of the generator rotor. The water-cooling system of the generator rotor is cleaned in a forward and reverse cycle, and sequentially undergoes the washing process before preheating, system preheating, alkali washing, water washing after alkali washing, pre-slow release, pickling, The process of water washing after pickling, pre-filming, and water washing after pre-filming completes the cleaning of the water cooling system of the generator rotor.

[0072] Among them, the generator rotor water cooling sy...

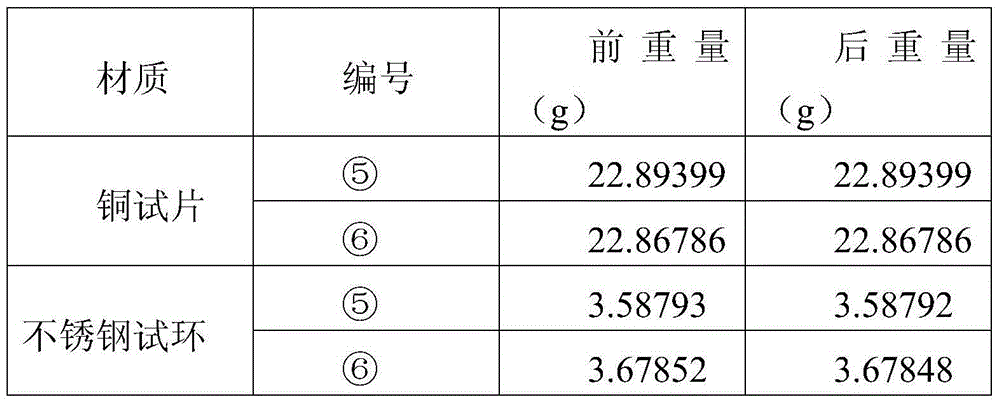

Embodiment 3

[0101] Take the coal-fired generator set QFS2-330-2 generator as an example:

[0102] Its cooling system is a double water cooling system, and the rotor winding of the double water internal cooling cooling method is water internal cooling. The factory test pressure of the internal cooling water system of the stator and rotor windings is 1MPa; the water pressure after installation is 0.75MPa.

[0103] 3.1 Cleaning process:

[0104] A cleaning process for the water-cooling system of the generator rotor. The water-cooling system of the generator rotor is cleaned in a forward and reverse cycle, and then undergoes system preheating, alkali cleaning, water washing after alkali cleaning, pre-sustained release, pickling, water washing after pickling, and pre-slow release. The process of water washing after film and pre-film completes the cleaning of the water cooling system of the generator rotor.

[0105] Among them, the generator rotor water cooling system includes the cooling wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com