ERW welding pipe on-line external burr removing technique

An external burr and welded pipe technology is applied in the field of on-line external burr removal technology for ERW welded pipes, which can solve the problems of reduced yield and increased production cost, and achieve the effect of easy operation and simple removal process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

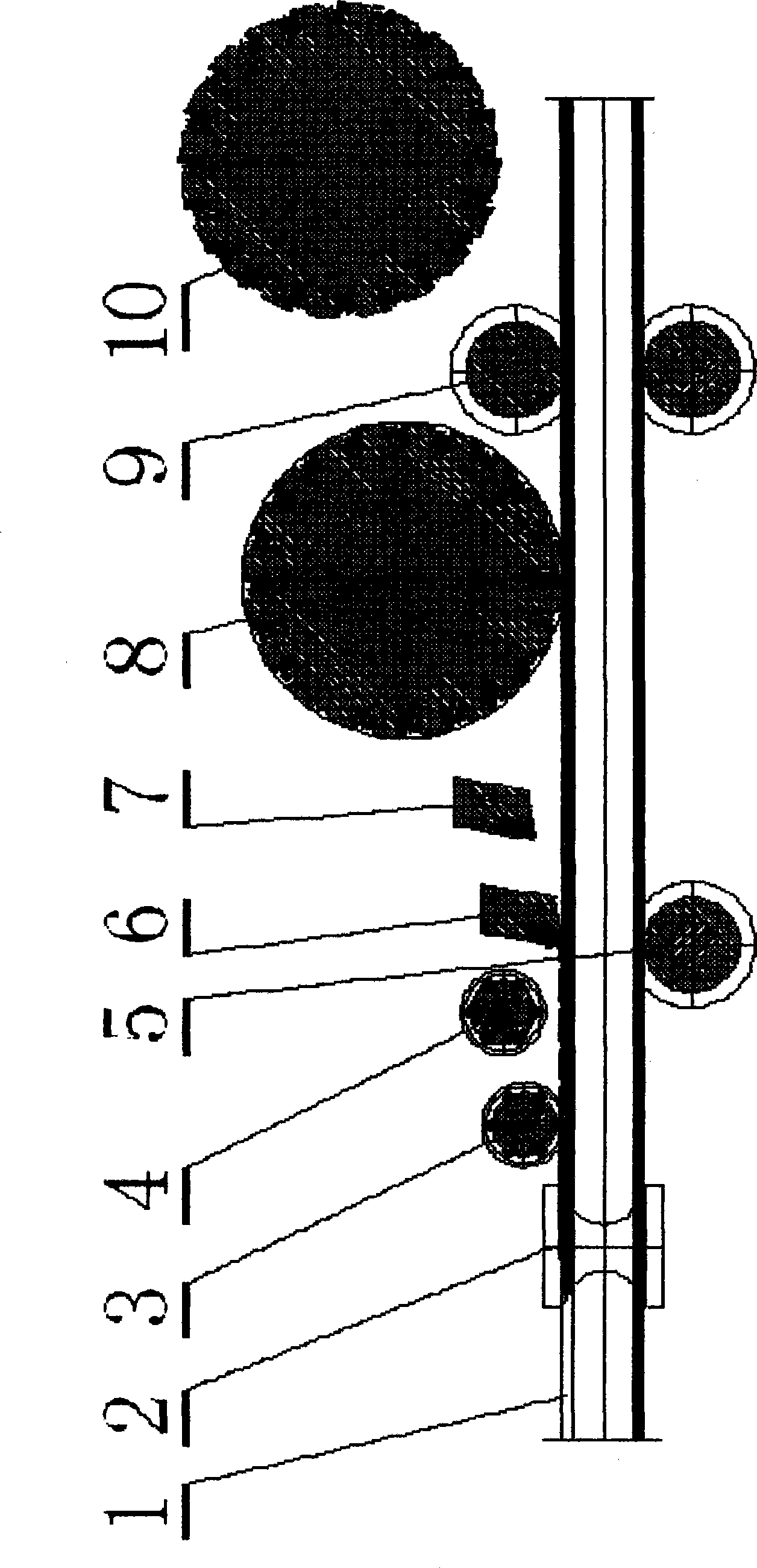

[0009] The specific embodiment and technical requirements of the present invention will be further described below in conjunction with the accompanying drawings.

[0010] An ERW welded pipe on-line external burr removal process is installed with external burr scoring rollers 3, 4, external burr planing devices 6, 7, external burr milling devices 8, 9, and scoring Roller, planing device, and milling device are all one-use and one-standby, and cooperate with idler roller 5, pressure roller 9, adjustment device, power system, hydraulic pressure and pneumatic system to realize the uninterrupted removal of burrs outside the weld seam throughout the length.

[0011] The outer diameter of the scoring roller is between Φ40~Φ300mm, and the outer diameter of the scoring is determined according to the size of the welded pipe production line. 3~18 scoring knives are evenly arranged on each scoring roller. The scoring roller does not need power, the scoring roller is pressed on the pipe, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com