Liquid wax for polished bonding sheet, preparation thereof and process of polished bonding sheet

A liquid wax and sticky sheet technology, applied in polishing compositions, chemical instruments and methods, etc., can solve the problems of environmental pollution, air bubbles, and inequality, and achieve the effects of no environmental pollution and simple cleaning process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

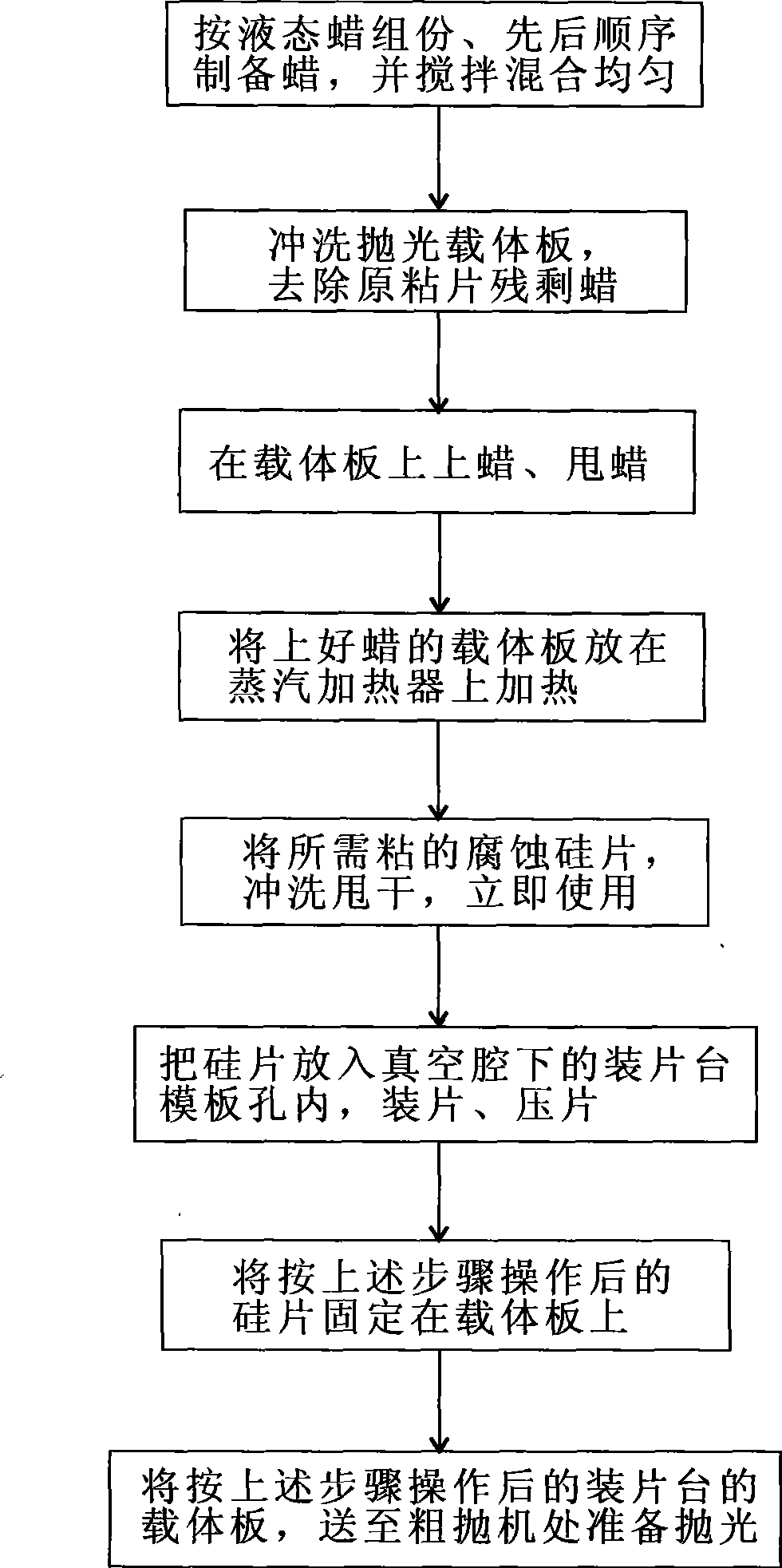

Method used

Image

Examples

Embodiment approach 1

[0033] The liquid wax for polishing adhesive sheet contains the following components (by 10,000 grams by weight):

[0034] Polyethylene glycol 662.3

[0035] Paint flakes 198.5

[0036] Isopropanol 548.7

[0037] 25% ammonia 307.0

[0038] 18 trillion deionized water 2347.8

[0039] 8030 resin 5913.1

[0040] Preparation of liquid wax for polishing adhesive sheet, its preparation steps are as follows:

[0041] (1), a wax bucket with a capacity of 10 liters is placed on the weighing balance, and the weighing balance is placed in the fume hood;

[0042] (2) Pour polyethylene glycol, paint flakes, isopropanol, 25% ammonia water, 18 trillion deionized water, and 8030 resin into the wax mixing bucket in sequence and mass fraction until the requirements are reached up to the reading;

[0043] (3) Slowly mix the ingredients by magnetic stirring for at least 3 hours; after stirring, let stand for 3 hours;

[0044] (4) When storing, the lid of the wax barrel should be tightly c...

Embodiment approach 2

[0056] The liquid wax for polishing adhesive sheet contains the following components (by 10,000 grams by weight):

[0057] Polyethylene glycol 664.0

[0058] Paint flakes 200.0

[0059] Isopropanol 550.0

[0060] 25% ammonia 308.4

[0061] 18 trillion deionized water 2350.6

[0062] 8030 resin 5927.0

[0063] Preparation of liquid wax for polishing adhesive sheet, its preparation steps are as follows:

[0064] (1), a wax bucket with a capacity of 10 liters is placed on the weighing balance, and the weighing balance is placed in the fume hood;

[0065](2) Pour polyethylene glycol PEGE-200, paint flakes, isopropanol, 25% ammonia water, 18 trillion deionized water, and 8030 resin into the wax mixing bucket in sequence and mass fraction, until the required reading is reached;

[0066] (3) Slowly mix the ingredients by magnetic stirring for at least 3 hours; after stirring, let stand for 3 hours;

[0067] (4) When storing, the lid of the wax barrel should be tightly closed;...

Embodiment approach 3

[0079] The liquid wax for polishing adhesive sheet contains the following components (by 10,000 grams by weight):

[0080] Polyethylene glycol 665.7

[0081] Paint flakes 201.5

[0082] Isopropanol 551.2

[0083] 25% ammonia 309.7

[0084] 18 trillion deionized water 2353.4

[0085] 8030 resin 5940.8

[0086] Preparation of liquid wax for polishing adhesive sheet, its preparation steps are as follows:

[0087] (1), a wax bucket with a capacity of 10 liters is placed on the weighing balance, and the weighing balance is placed in the fume hood;

[0088] (2) Pour polyethylene glycol PEGE-200, paint flakes, isopropanol, 25% ammonia water, 18 trillion deionized water, and 8030 resin into the wax mixing bucket in sequence and mass fraction, until the required reading is reached;

[0089] (3) Slowly mix the ingredients by magnetic stirring for at least 3 hours; after stirring, let stand for 3 hours;

[0090] (4) When storing, the lid of the wax barrel should be tightly closed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com