Monocrystal texturing cleaning machine and technological method therefor

A cleaning machine and single crystal technology, applied in chemical instruments and methods, sustainable manufacturing/processing, crystal growth, etc., can solve the problems of unprovided equipment and automatic cleaning, and achieve safe and stable operation, saving labor costs, High cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

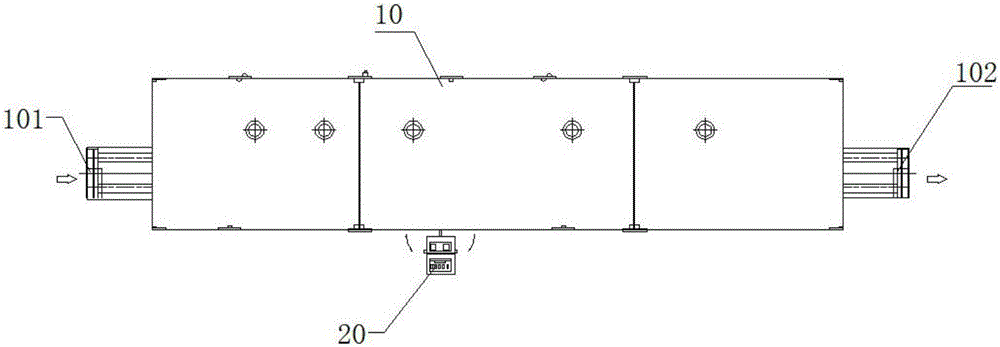

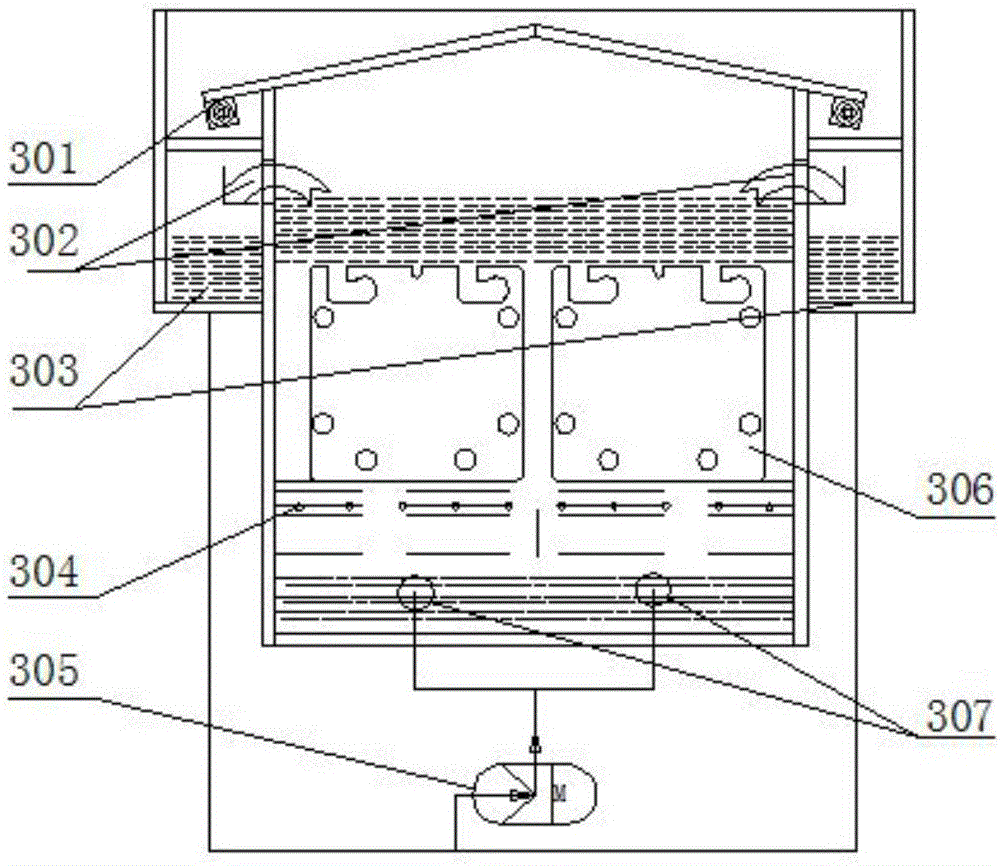

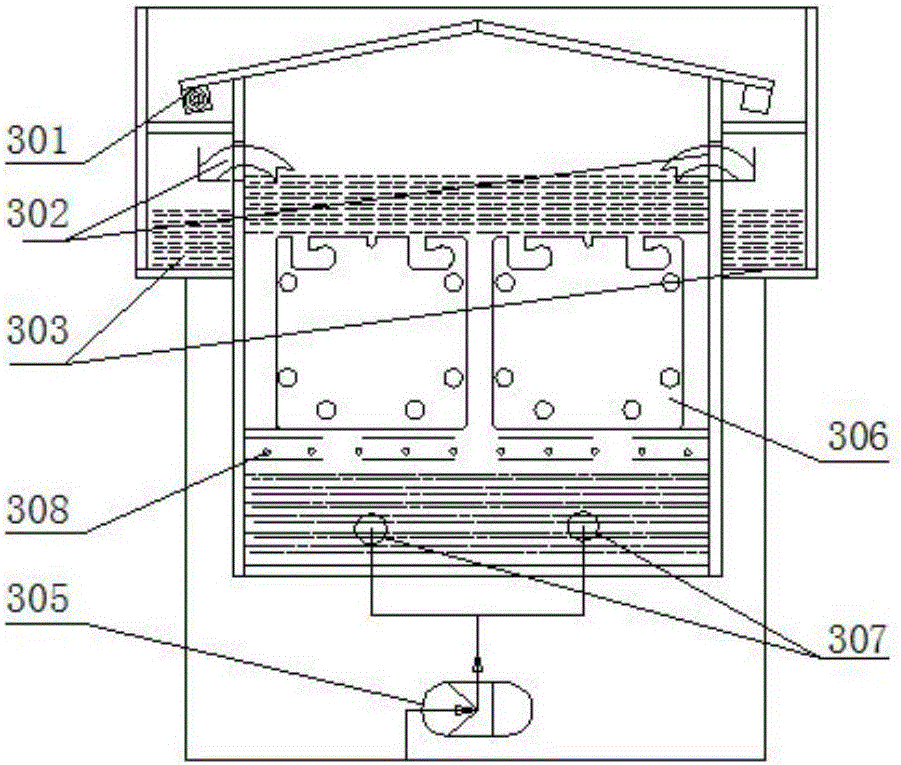

[0034] Such as figure 1 As shown, a single crystal texturing cleaning machine includes a cleaning body 10. The cleaning body 10 includes three boxes. The positions of the feed port 101 and the discharge port 102 are respectively provided with a conveyor belt, and a plurality of manipulators for grabbing materials are arranged above the conveyor belt. One side of the cleaning body 10 is provided with a cleaning process for regulating and controlling the cleaning process in the cleaning body 10, and the cleaning process is carried out. The control cabinet 20 for real-time monitoring, the upper cover of the cleaning body 10 is provided with an air outlet, and the cleaning body 10 is also provided with a cashmere tank, pickling tank, water washing tank, pre-dehydration tank and drying tank, each tank body A heating device and a temperature sensor are provided, and a liquid dispensing and replenishing system connected to each tank body is also provided in the cleaning body 10 .

...

Embodiment 2

[0042] This embodiment provides a single crystal texturing cleaning process, which specifically includes the following steps:

[0043] S1. Put the silicon wafers into the flower basket, send it to the feeding port through the conveyor belt, and grab the flower basket by the manipulator and send it to the texturing tank, pickling tank, water washing tank, pre-dehydration tank and drying tank in turn;

[0044] S2. The processes of pre-cleaning, warm water rinsing, texturing corrosion, pure water rinsing, pickling, pre-dehydration and drying are respectively carried out by the texturing tank, pickling tank, water washing tank, pre-dehydration tank and drying tank;

[0045] S3. After being processed by the texturing tank, pickling tank, water washing tank, pre-dewatering tank and drying tank, the flower basket is picked up by the manipulator, placed on the conveyor belt, and sent to the discharge port.

[0046] In this embodiment, it is set to include real-time monitoring of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com