Cement barrel cleaning equipment for construction site

A technology for cleaning construction sites and barrels, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., and can solve the problems of time-consuming and labor-intensive cleaning process and the inability to clean cement barrels, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

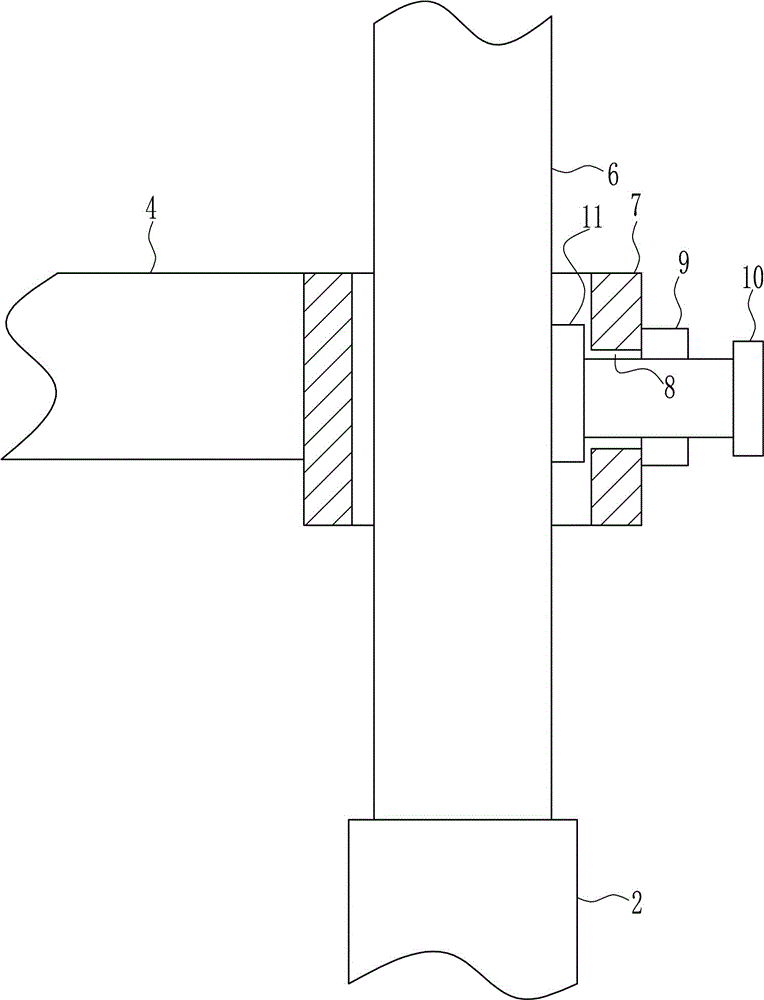

[0039] A cement bucket cleaning equipment for a construction site, such as Figure 1-7 As shown, it includes a bottom plate 1, a support rod 2, a fixing device 3, a first guide rail 4 and a cleaning device 5 in the bucket. In the device 3, a first guide rail 4 is installed on the left side of the upper side of the support rod 2 by welding, and the first guide rail 4 is provided with a cleaning device 5 in the bucket.

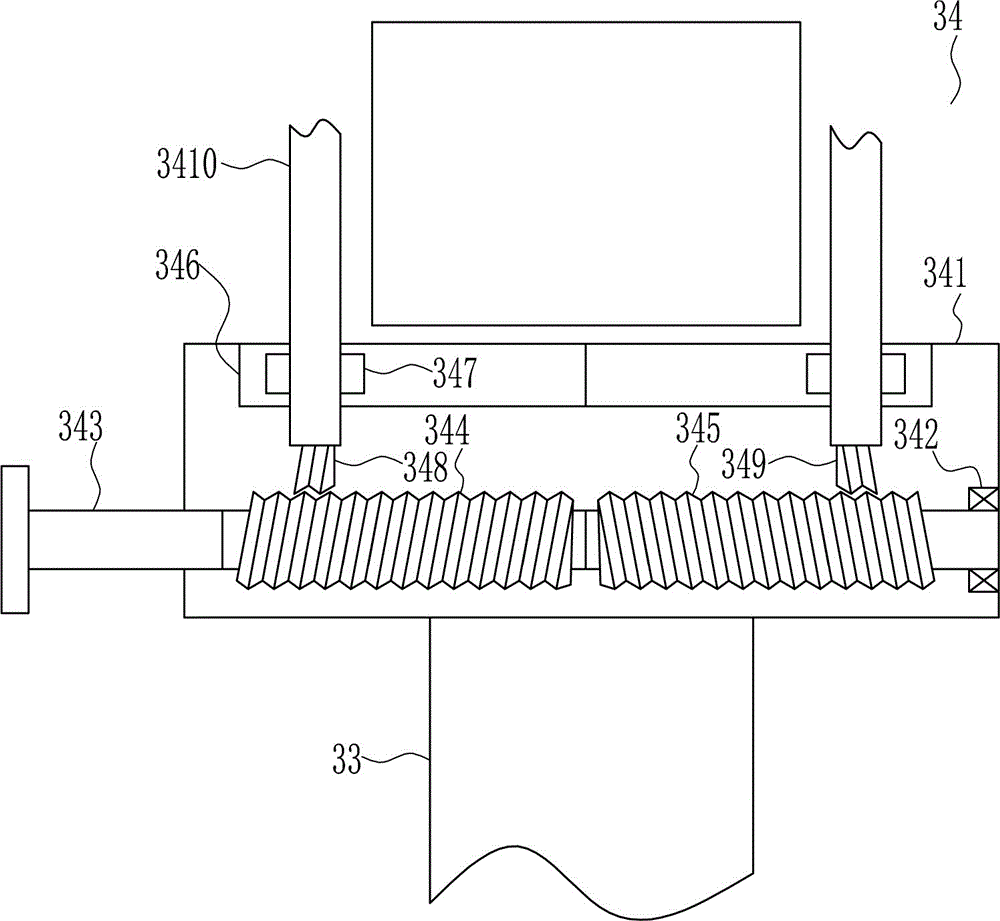

[0040] The fixing device 3 includes a first support plate 31, a first bearing seat 32, a first rotating rod 33, a fixed seat 34, a first gear 35, a first motor 36, a second gear 37, a pulley 38, a fixed plate 341, a first Two bearing housings 342, the second rotating rod 343, the forward screw screw 344, the reverse screw screw 345, the first slide rail 346, the first slide block 347, the forward thread block 348, the reverse thread block 349 and the pressing plate 3410 support rod 2 The first support plate 31 is installed on the left side of the lower side by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com