Helical motion type pipeline surface cleaning mechanical arm

A surface cleaning and moving technology, applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of high cost, time-consuming and low efficiency of equipment and use, and achieve convenient and easy installation , clean up thoroughly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

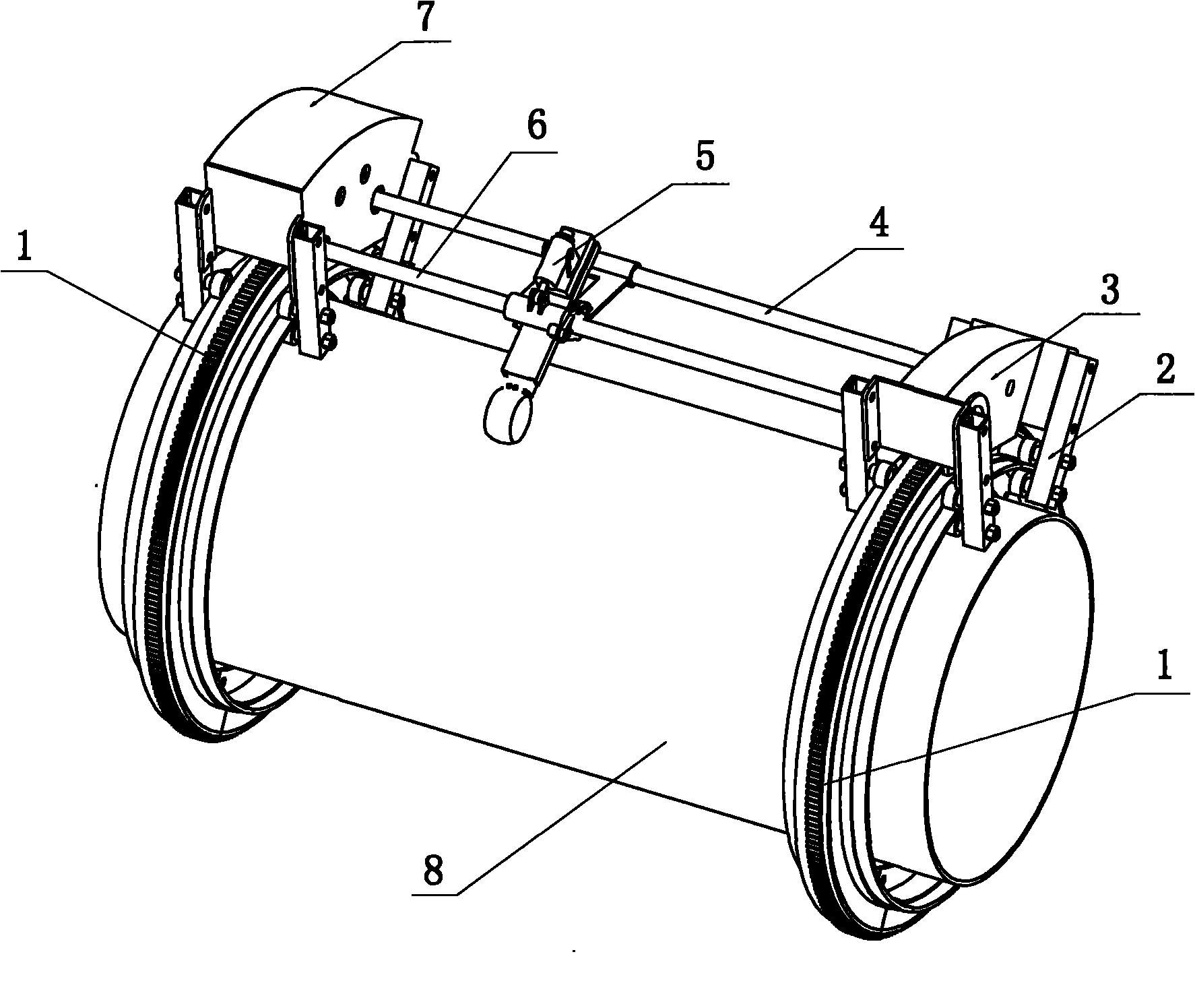

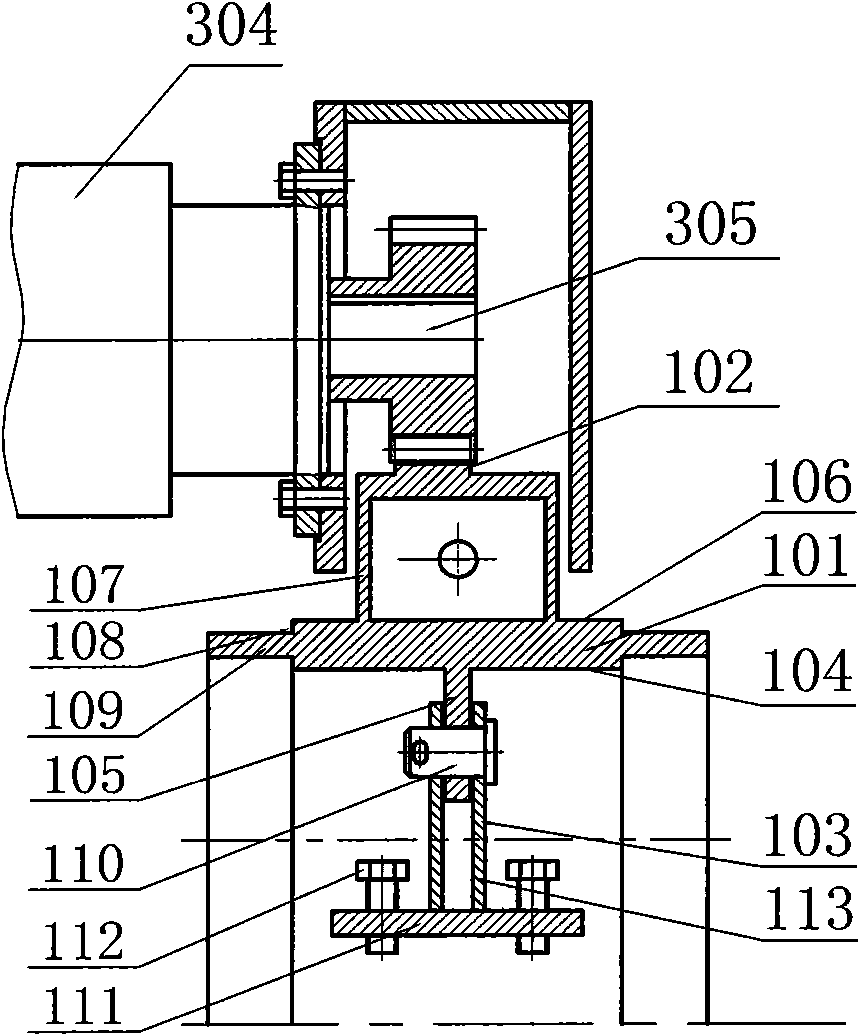

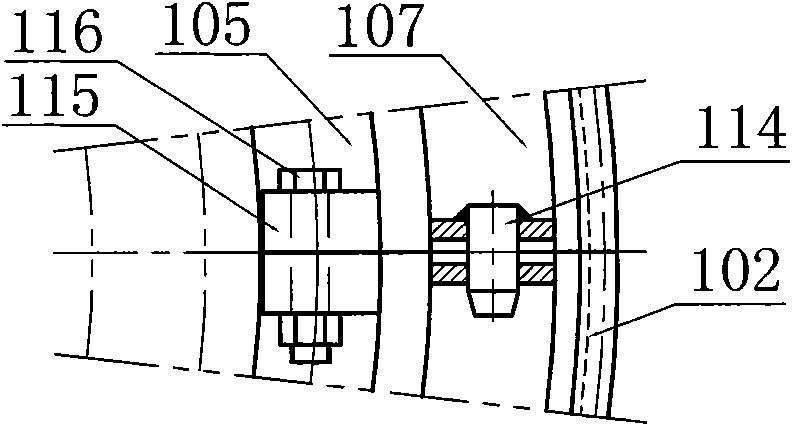

[0044] Embodiment 1: as Figure 1 ~ Figure 4 As shown, the present invention includes ring gear track 1, support 2, driving box 3, driven box 7, lead screw 6, feed rod 4, working device 5 and power supply device 9, and described ring gear track 1 is two, respectively Fixed on the pipeline by bolts, the active box 3 and the driven box 7 are respectively supported on the ring gear track 1 through the bracket 2 with rollers, the first gear in the active box 3 connected with the output shaft of the motor reducer is installed on the light The second gear at one end of the bar and the fourth gear on the input shaft in the driven box 7 mesh with the ring gear track 1 respectively, and rotate relatively along the ring gear track 1. The other end of the light rod 4 is connected with the input shaft of the driven box 7. One end of the leading screw 6 is connected with the output shaft of the driven box, and the other end is supported on the casing of the driving box. The leading screw 6...

Embodiment 2

[0054] Embodiment 2: The overall structure of this embodiment is the same as that of Embodiment 1, the difference is that the steel brush wheel 505 described in this embodiment is a steel brush. There are 3 adjusting legs on the ring gear track 1, which are evenly distributed on the ring plate 105 of the inner wall 104 of the track frame; the ring track 901 legs 910 of the power supply device 9 are 4, which are evenly distributed on the ring connecting plate 906 superior.

Embodiment 3

[0055] Embodiment 3: The overall structure of this example is the same as that of Embodiment 1, the difference is that in this example, there are 5 adjusting legs on the ring gear track 1, which are evenly distributed on the annular plate 105 of the inner wall 104 of the track frame; There are five supporting legs 314 of the power supply device 305 in the box 3, which are evenly distributed on the annular connecting plate 313 thereof.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com