Method and appts. for reducing discharge of nitrogen oxide in selective catalytic reduction system

A technology of equipment and reducing agent, which is applied in the direction of chemical instruments and methods, separation methods, mechanical equipment, etc., can solve the problems of solidified storage tank liner pumps, damage, unacceptable evaporative emissions, etc., and achieve the effect of eliminating the loss of reducing agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

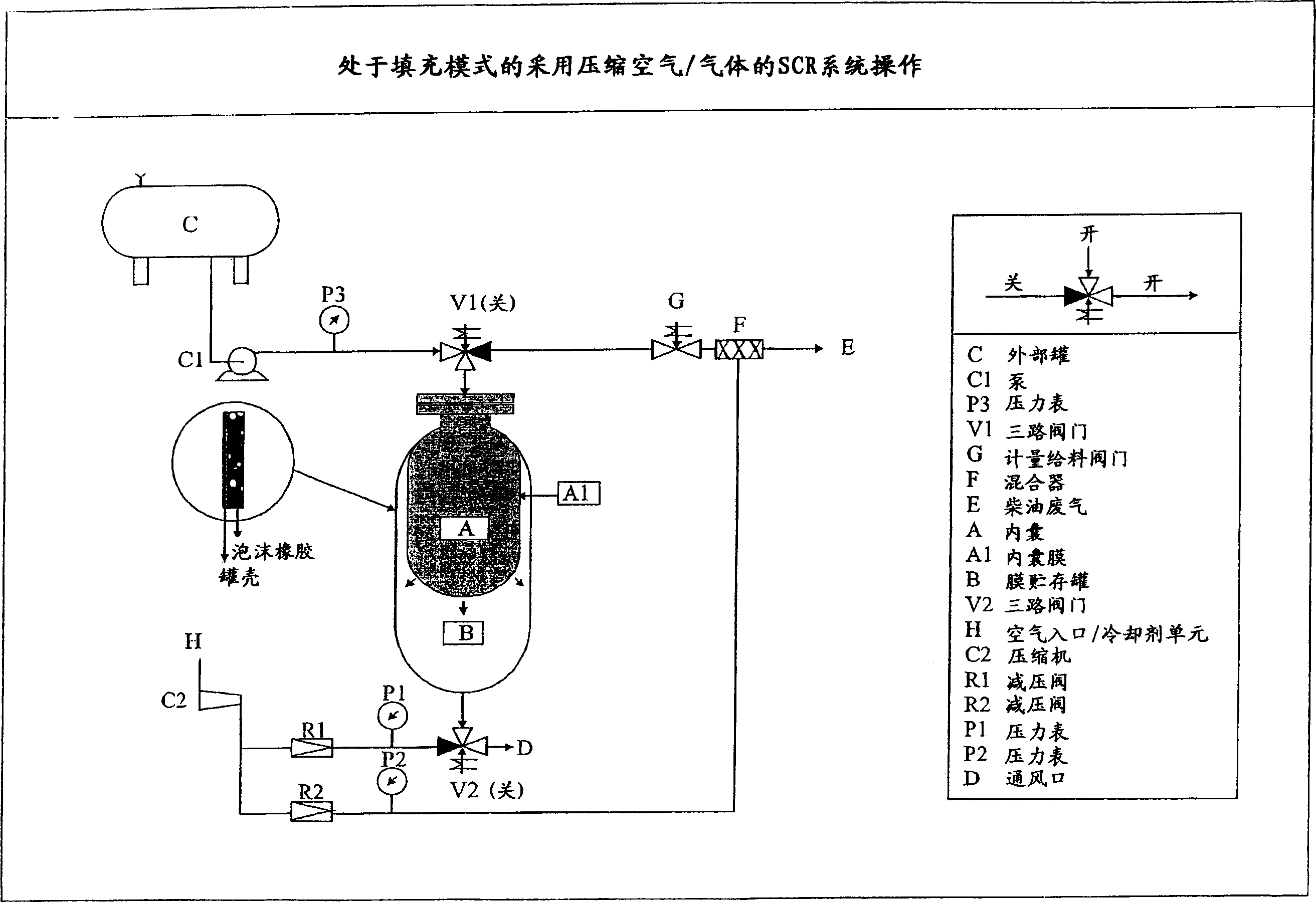

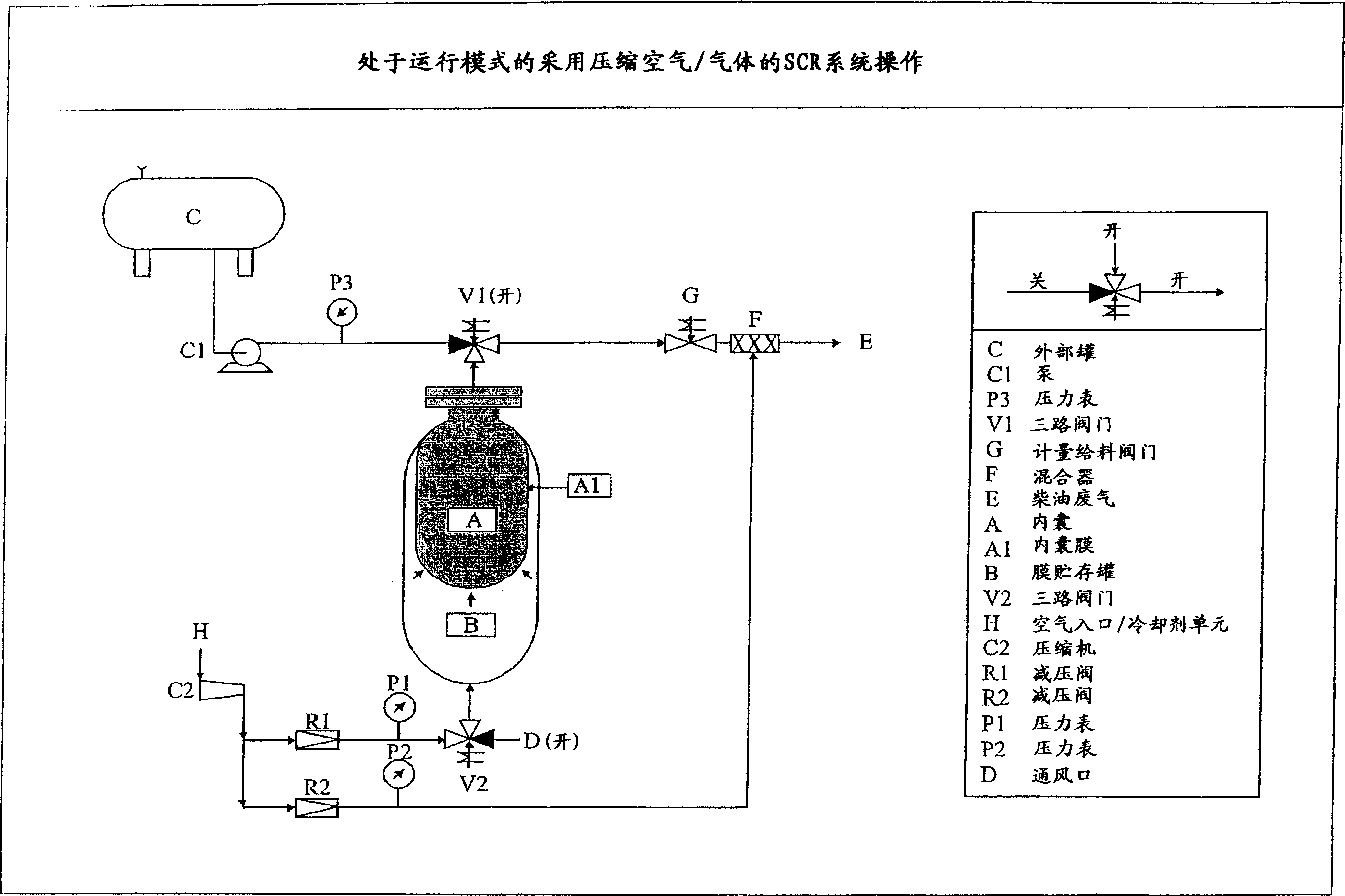

[0068] Build and test a system as described above. The inner capsule A was filled with a 32.5 wt / wt% aqueous urea solution. Turn valves V1 and V2 to "open" position (running mode). Adjust the pressure regulator R1 to 2 bar (2×10 5 Pa). The carrier air entering the mixer F is adjusted to 1 bar (1×10 5 Pa). By actuating the dosing valve G, a constant urea flow into the exhaust gas E is established. Example 2

Embodiment 2

[0069] Fill inner capsule A with 25% ammonia water instead of urea solution. The pressure setting is identical to Example 1. A constant ammonia flow is established by actuating the dosing valve G.

Embodiment 3

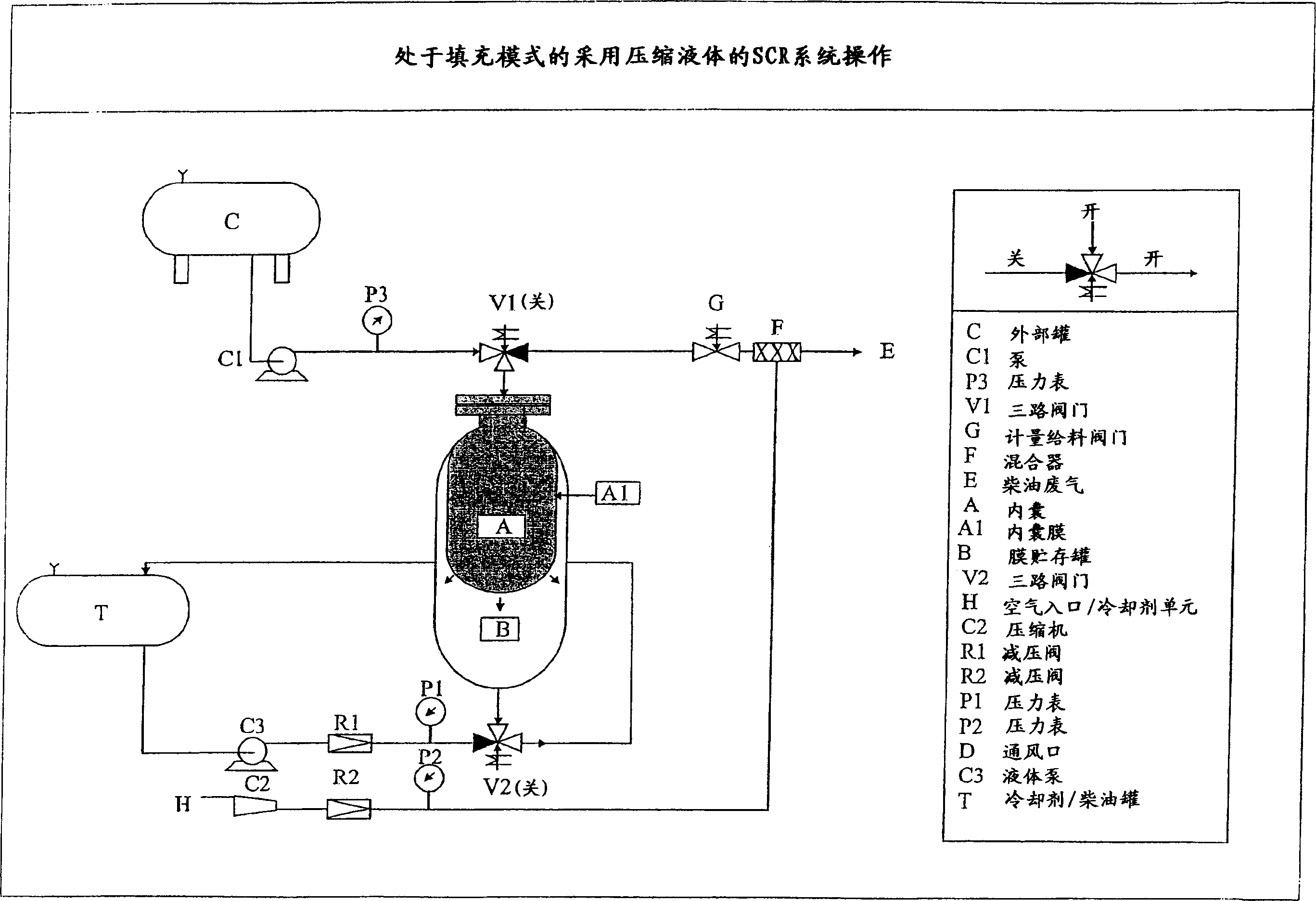

[0071] As Example 1, but in this case coolant liquid from tank T is used instead of compressed air. The coolant is pumped out via pump C3. On the pressure reducing valve R1, adjust the flow pressure to 2 bar (2×10 5 Pa). Liquid flow is delivered to tank B through V2 in the "on" position. Compress the urea contained in inner capsule A to 2 bar (2×10 5 Pa) equivalent pressure. As in Example 1, the flow of urea into mixer F was established.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com