Plasma-generating source comprising a belt-type magnet, and thin-film deposition system using same

A technology of plasma and generating source, applied in the field of plasma generating source, can solve the problems of reducing plasma density, weakening process reliability, reducing microwave transmittance, etc., and achieves the effect of improving the mean free path and improving the straightness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

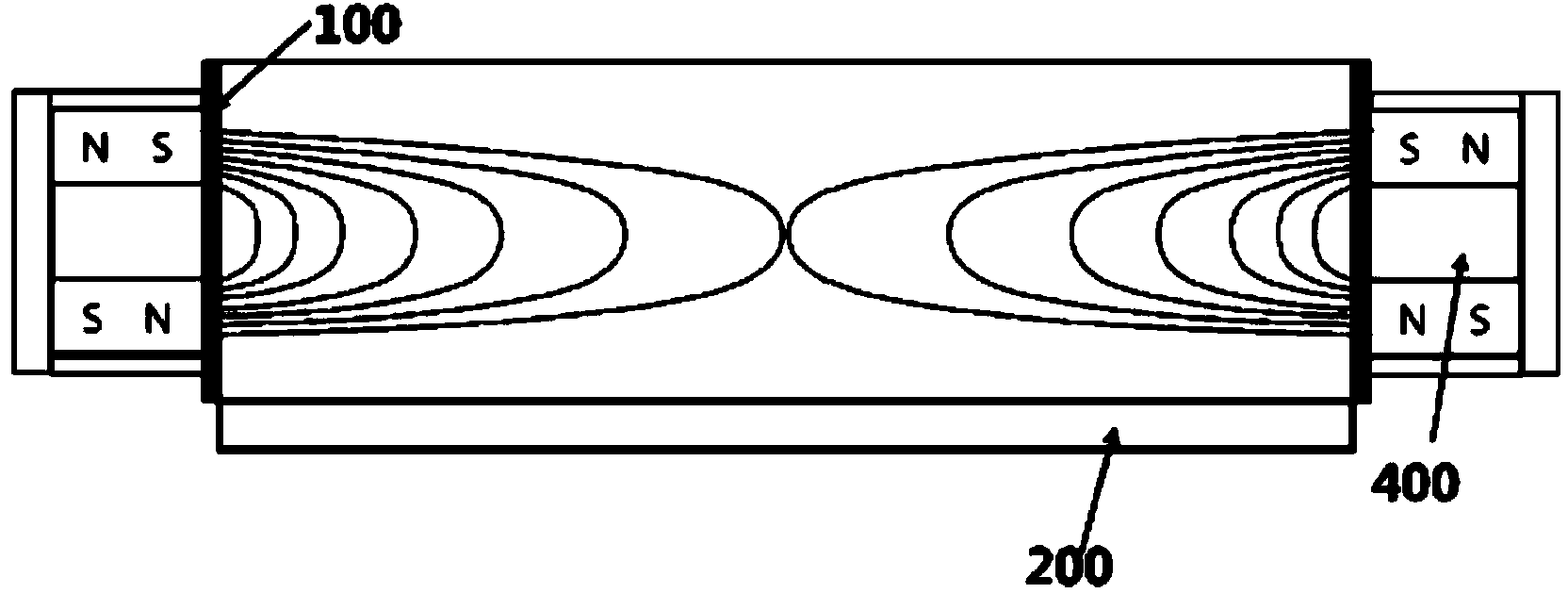

[0084] Below, the detailed description is based on Figure 1a to Figure 1d The modified embodiment of the plasma generation source and the sputtering device, neutral particle beam generation source and thin film deposition system based on its application.

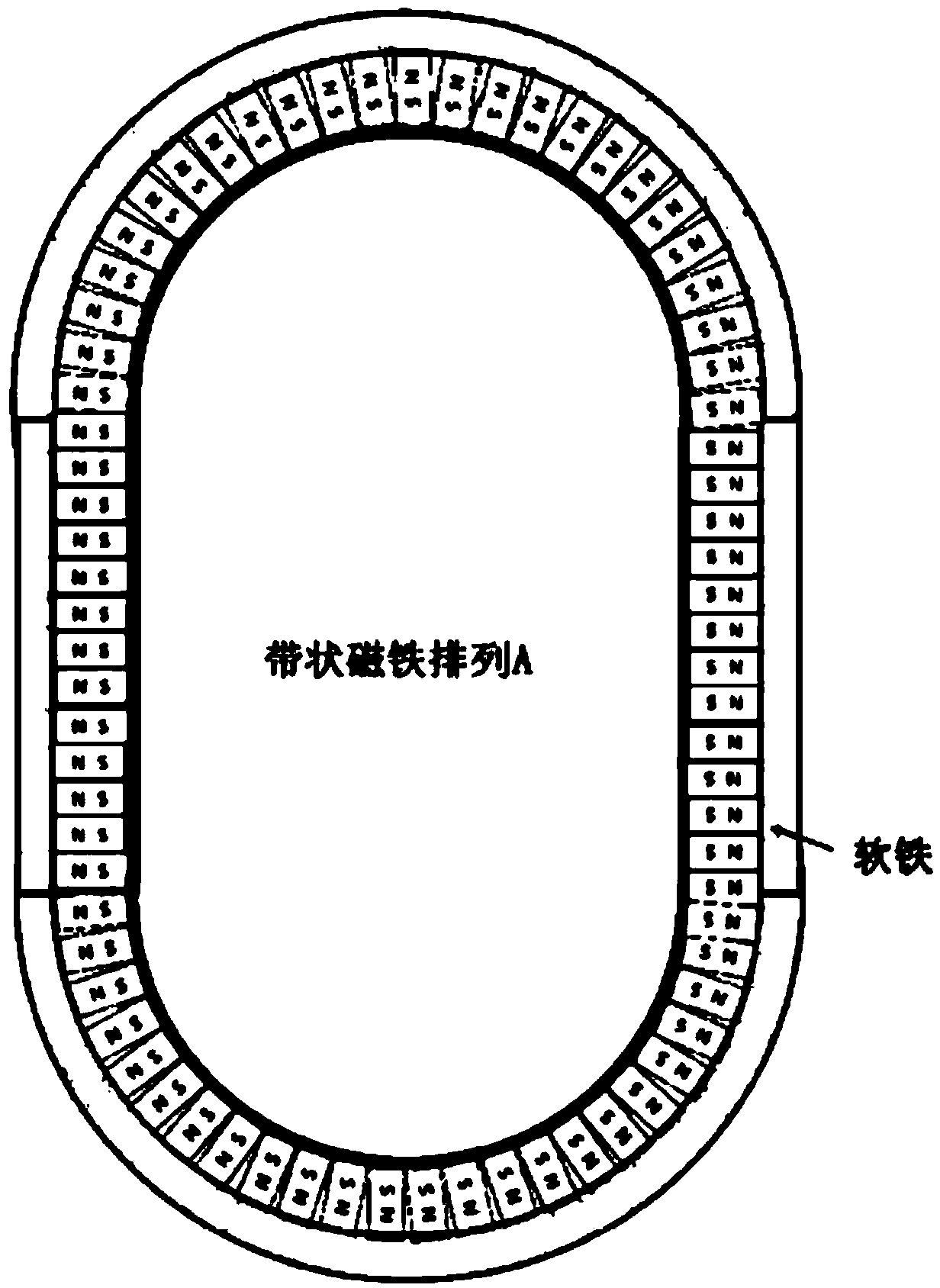

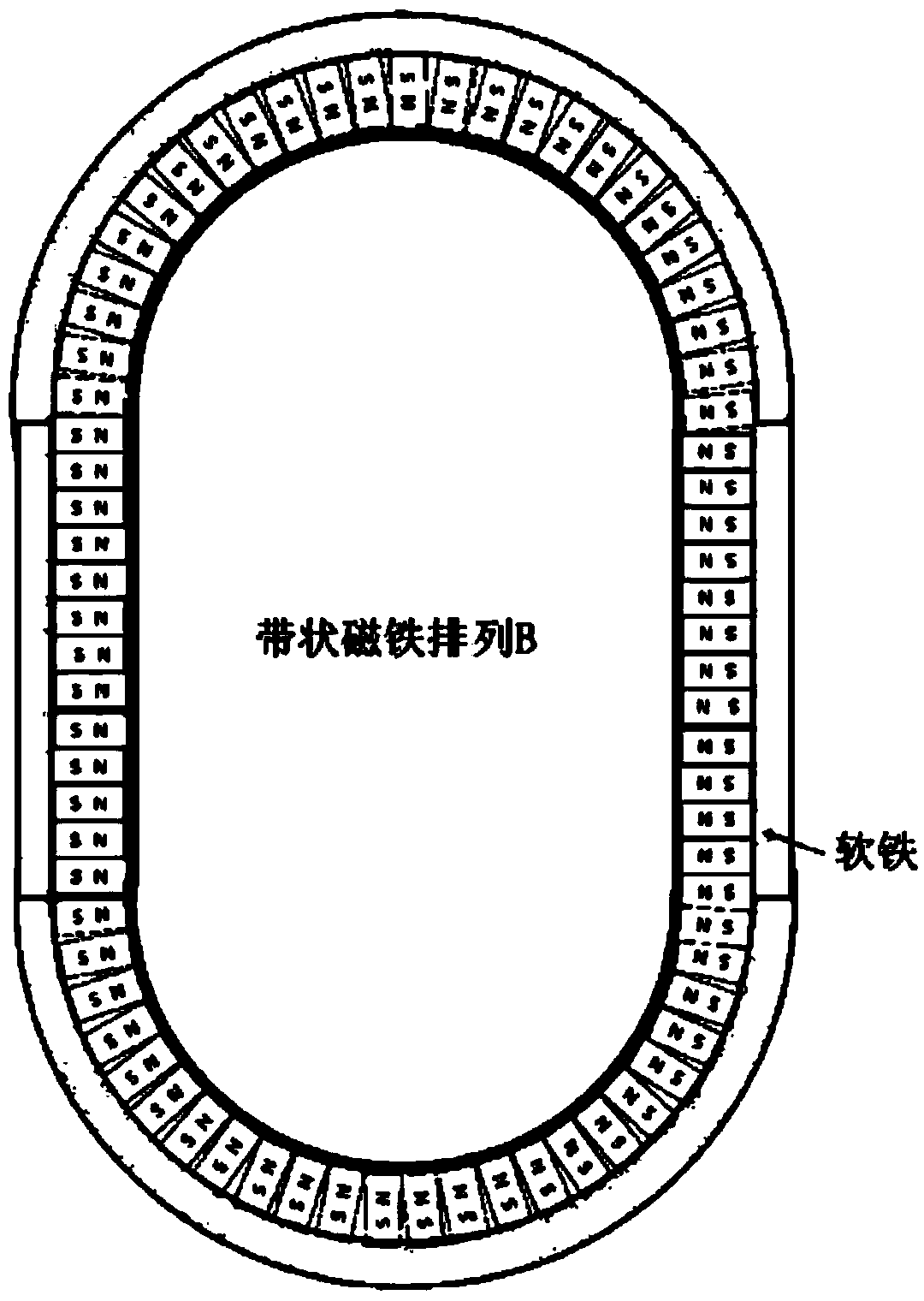

[0085] observation from above Figure 1a and Figure 1d When the microwave irradiation device 200 is irradiated, it takes a shape such as a circle, an ellipse, an orbital shape using a circle, an ellipse, or a quadrilateral. figure 2 shows the situation where the slit 250 is formed on the microwave irradiation device 200, image 3 A case where a slit is formed in a circular microwave irradiation device 200 is shown in , Figure 4 A quadrangular or cylindrical microwave irradiation device 200 is shown, and a plurality of such microwave irradiation devices 200 may be provided to enhance output.

[0086] refer to Figure 5 , shows a sputtering device 800 using the plasma generation source. The sputtering device 800 is ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com