Beta phase polyvinylidene fluoride composite film and preparation method thereof

A technology of polyvinylidene fluoride and composite film, which is applied in the field of β-phase polyvinylidene fluoride composite film and its preparation, to achieve good temperature stability and increase the effect of content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

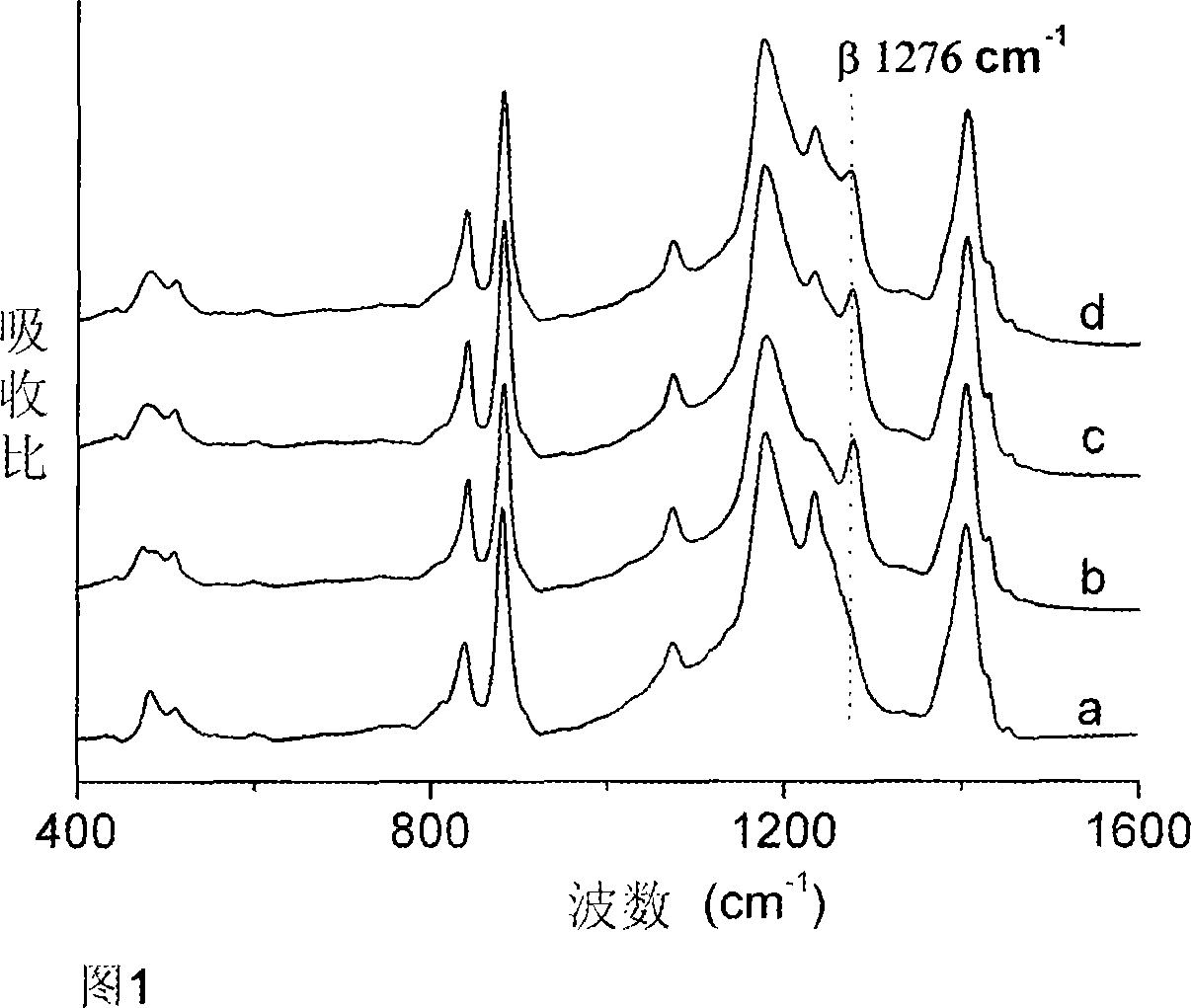

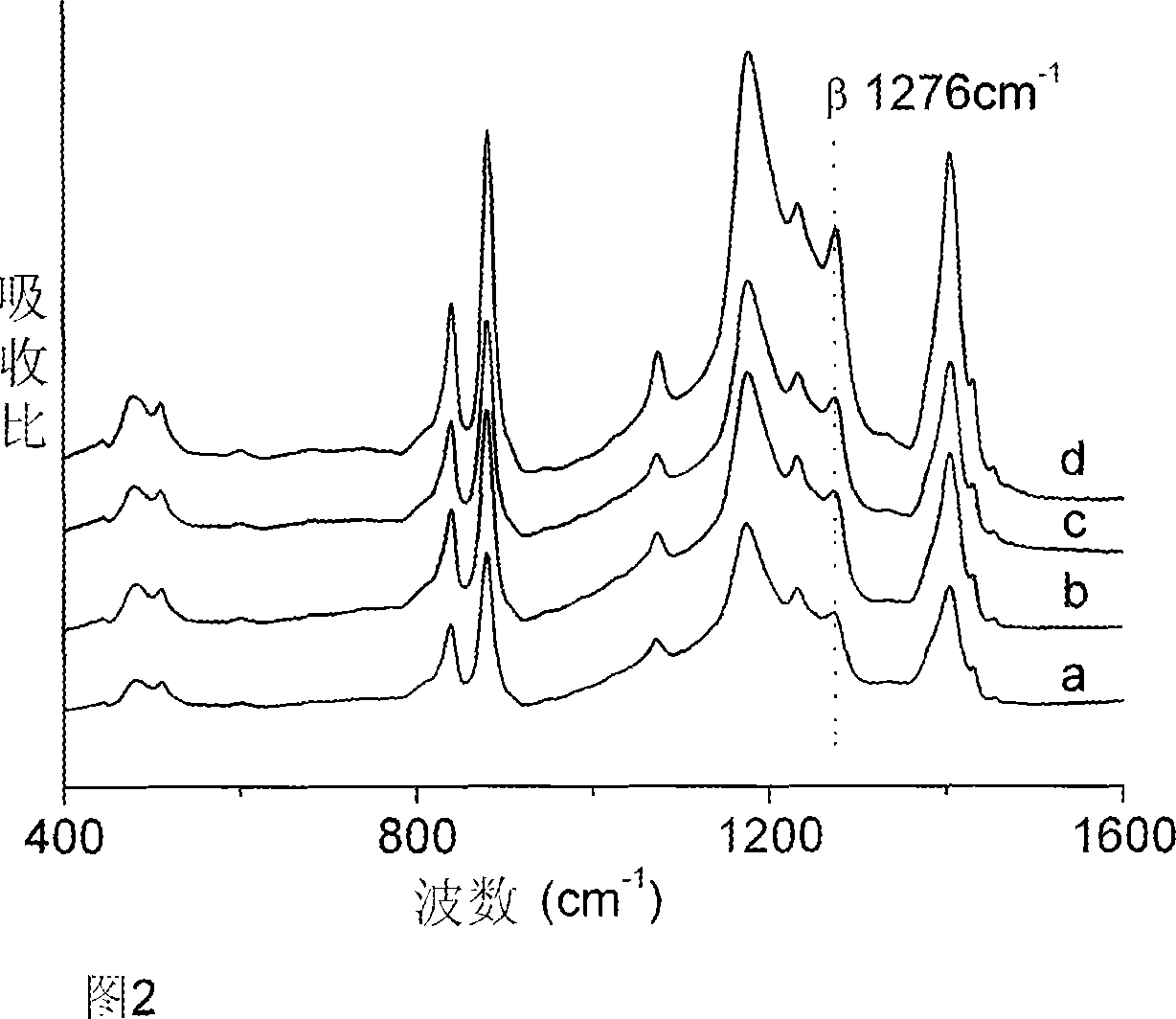

Embodiment 1

[0017] Fe(NO 3 ) 3 9H 2 O and PVDF-HFP with a mass percentage concentration of 95% were dissolved in DMF, and a solution with a mass percentage concentration of 20% was prepared. The solution was stirred, mixed evenly, spin-coated on a glass substrate, and crystallized and evaporated at 60 ° C for 24 hours. A β-phase PVDF film was obtained. The test results are shown in Figure 1.

Embodiment 2

[0019] Concentration by mass percentage is 5% Fe(NO 3 ) 3 9H 2 O and PVDF-HFP with a mass percentage concentration of 95% were dissolved in DMF, and a solution with a mass percentage concentration of 20% was prepared. The solution was stirred, mixed evenly, spin-coated on a glass substrate, and crystallized and evaporated at 60 ° C for 24 hours. A β-phase PVDF film was obtained. The results are reported in Figure 1.

Embodiment 3

[0021] Co(NO 3 ) 2 ·6H 2 O and PVDF-HFP with a mass percentage concentration of 95% were dissolved in DMF to prepare a solution with a mass percentage concentration of 20%. On the substrate, crystallize and evaporate at 60°C for 24 hours to obtain a β-phase PVDF film. The results are reported in Figure 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com