Micro-nano channel structure tetragonal phase batio 3 The preparation method of /ha hollow microspheres

A technology of pore structure and hollow microspheres, which is applied in the field of bioceramic materials, can solve the problems of reduced flexural strength and fracture toughness, HA fracture toughness, and mechanical properties of flexural strength, which cannot be satisfied, and achieve excellent biocompatibility , Degradation rate ideal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

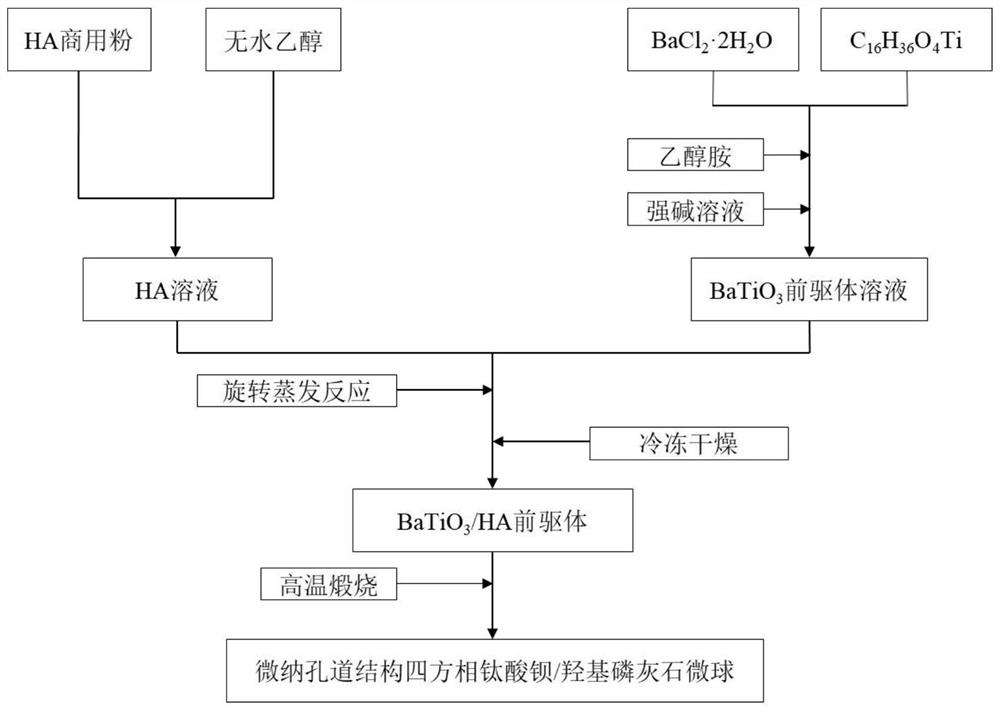

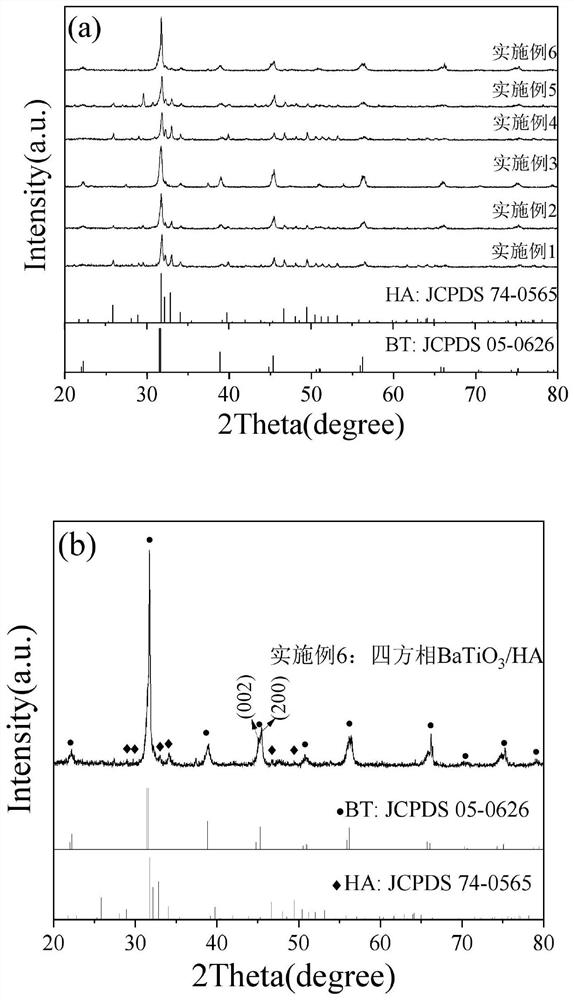

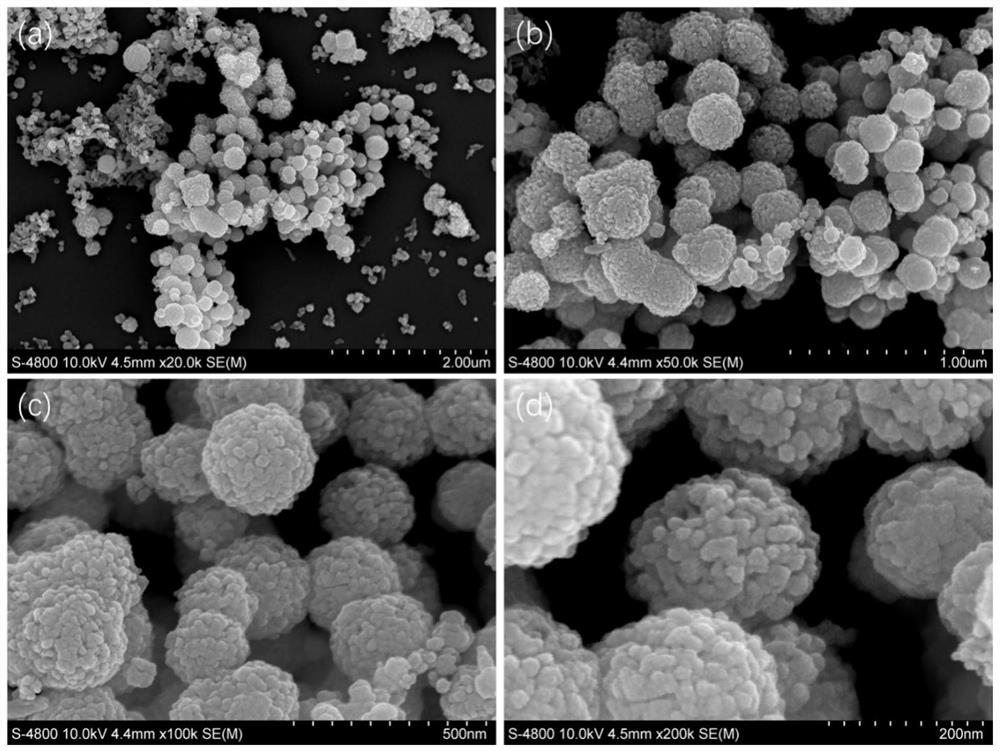

[0031] see Figure 1-4 , the present invention provides a technical solution: tetragonal BaTiO with micro-nano pore structure 3 / HA hollow microsphere preparation method, such as figure 1 As shown in the process flow chart, the specific operation steps are as follows:

[0032] Step 1, Formulation of BaTiO 3 Precursor solution: BaCl 2 ·2H 2 O and C 16 H 36 O 4 Ti is used as raw material, ethanolamine is used as reaction chelating agent, and BaTiO is obtained by reaction under high-concentration alkaline conditions 3 Precursor solution; the BaCl 2 ·2H 2 The weight of O is 1.8-10.5g, C 16 H 36 O 4 The weight of Ti is 3.5-21g, the weight of ethanolamine is 0.6-3.6g, the high-concentration alkaline condition selects NaOH aqueous solution, and the weight of NaOH is 2.5-25g;

[0033] Step 2, prepare HA solution: commercial HA nano-powder is dispersed in dehydrated alcohol to obtain HA solution; the weight of described commercial HA nano-powder is 10g, and the volume of d...

Embodiment 1

[0039] Step 1, Formulation of BaTiO 3 Precursor solution: first weigh 1.8g BaCl 2 ·2H 2 Add 10 mL of deionized water and stir until completely dissolved, and add 0.6 g of ethanolamine by weighing and stir to obtain a barium salt solution; then weigh 3.5 g of C 16 H 36 O 4 Dissolve Ti in 5 mL of absolute ethanol, stir evenly to obtain a titanium salt solution; finally weigh 2.5 g of NaOH and slowly dissolve it in 10 mL of deionized water to obtain a strong alkali solution; mix the barium salt solution, titanium salt solution and strong alkali solution. , a white turbid liquid is obtained, which is BaTiO 3 presomatic solution;

[0040] Step 2, prepare HA solution: take 10g of commercial HA nanopowder and dissolve it in 50mL absolute ethanol, stir to obtain HA solution;

[0041] Step 3, prepare PVA binder: according to the weight ratio of PVA and deionized water is 1:100, weigh 1 g of PVA into a beaker and add 100 mL of deionized water, and stir under heating in a water bat...

Embodiment 2

[0046] Step 1, Formulation of BaTiO 3 Precursor solution: first weigh 7.5g BaCl 2 ·2H 2 Add 30 mL of deionized water and stir until completely dissolved, and add 1.8 g of ethanolamine to it, and stir to obtain a barium salt solution; then weigh 10.5 g of C 16 H 36 O 4 Dissolve Ti in 15 mL of absolute ethanol, stir evenly to obtain a titanium salt solution; finally weigh 7.5 g of NaOH and slowly dissolve it in 30 mL of deionized water to obtain a strong alkali solution; mix and stir the barium salt solution, titanium salt solution and strong alkali solution evenly , a white turbid liquid is obtained, which is BaTiO 3 presomatic solution;

[0047] Step 2, prepare HA solution: take 10g of commercial HA nanopowder and dissolve it in 50mL absolute ethanol, stir to obtain HA solution;

[0048] Step 3, prepare PVA binder: according to the weight ratio of PVA and deionized water is 1:100, weigh 1 g of PVA into a beaker and add 100 mL of deionized water, and stir under heating in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com