Patents

Literature

32results about How to "Excellent osteoinductive properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bone matrix material containing various proteins secreted by umbilical cord mesenchymal stem cells and preparation method thereof

ActiveCN103480040AStrong osteoinductive activityGood osteoinductive functionSkeletal/connective tissue cellsProsthesisBone tissueTissue engineered bone

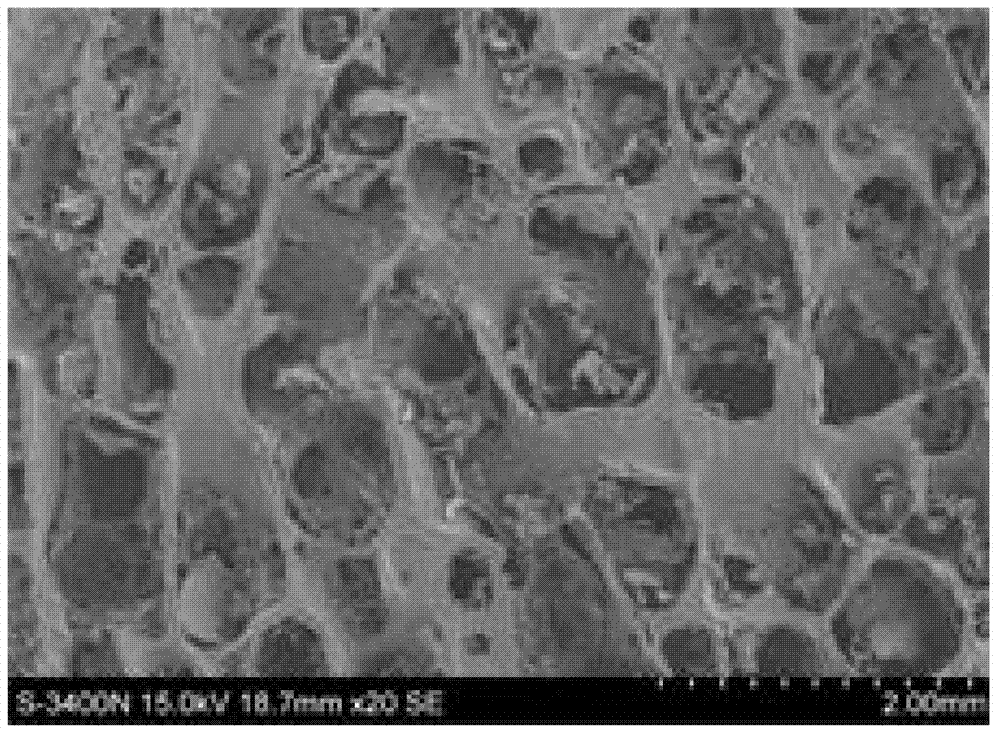

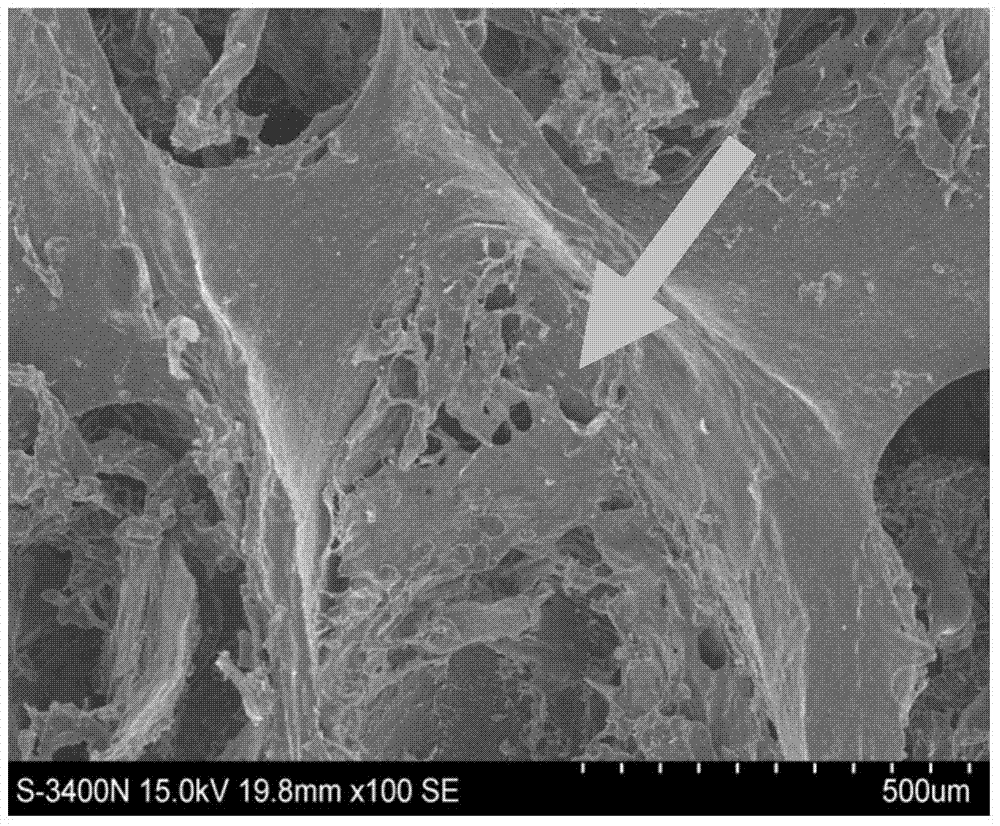

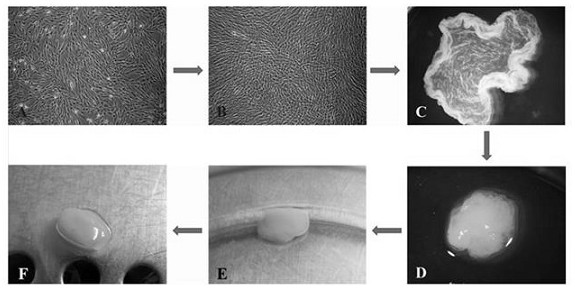

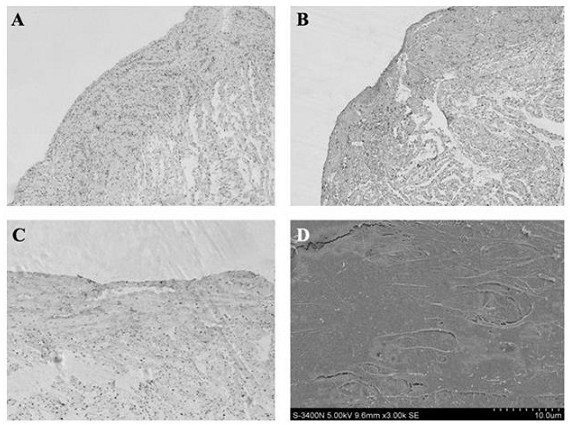

The invention relates to a bone matrix material containing various proteins secreted by umbilical cord mesenchymal stem cells and a preparation method thereof. The material is an animal bone matrix material with the umbilical cord mesenchymal stem cells inoculated on the surface of a decalcified bone matrix and used for secreting osteogenic induction function proteins to promote osteogenesis. The bone matrix material has natural structures and characteristics of bone tissues and a good osteogenic induction effect, has a better osteogenesis promoting effect in a bone defect repair process, and is helpful for large-scale preparation and clinical application of tissue-engineered bones.

Owner:THE FIRST AFFILIATED HOSPITAL OF THIRD MILITARY MEDICAL UNIVERSITY OF PLA

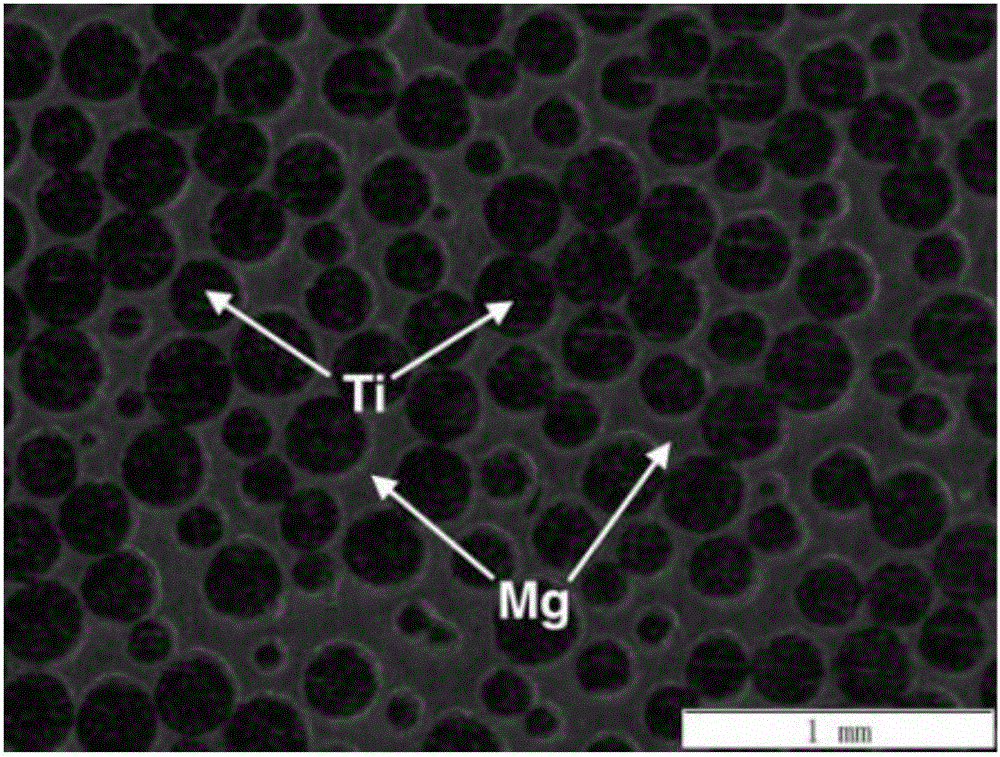

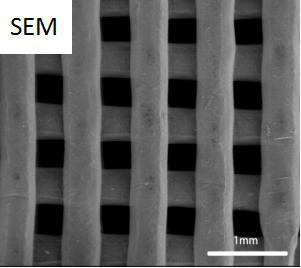

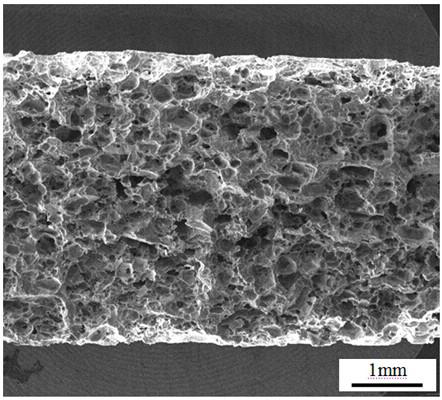

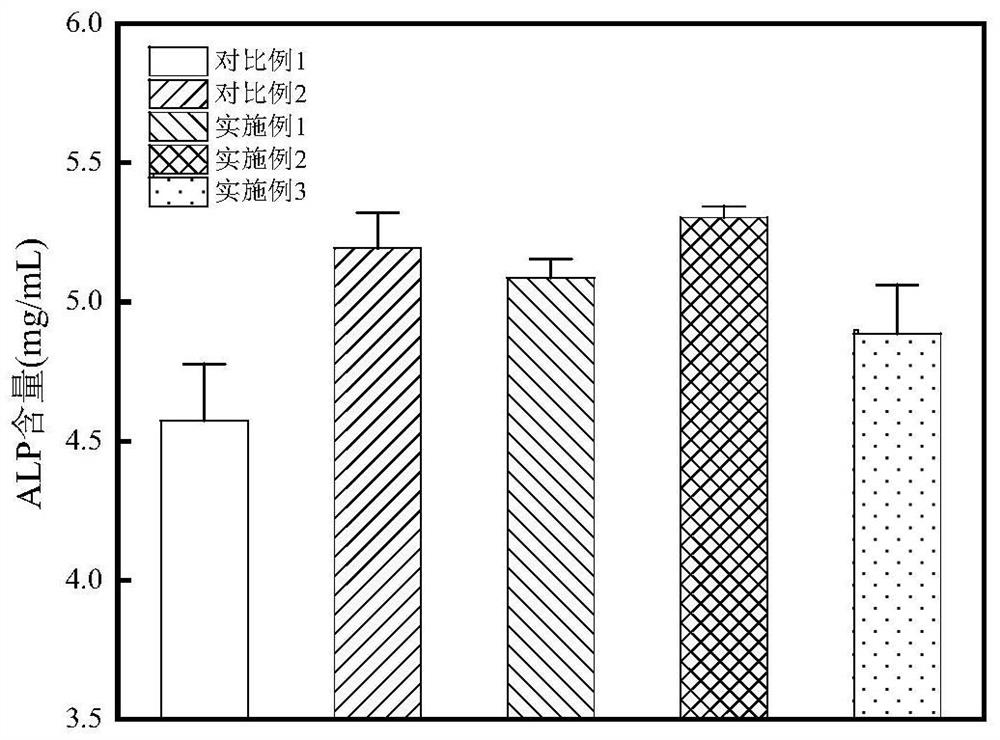

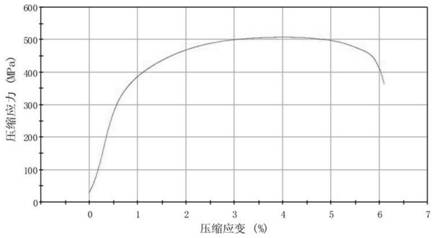

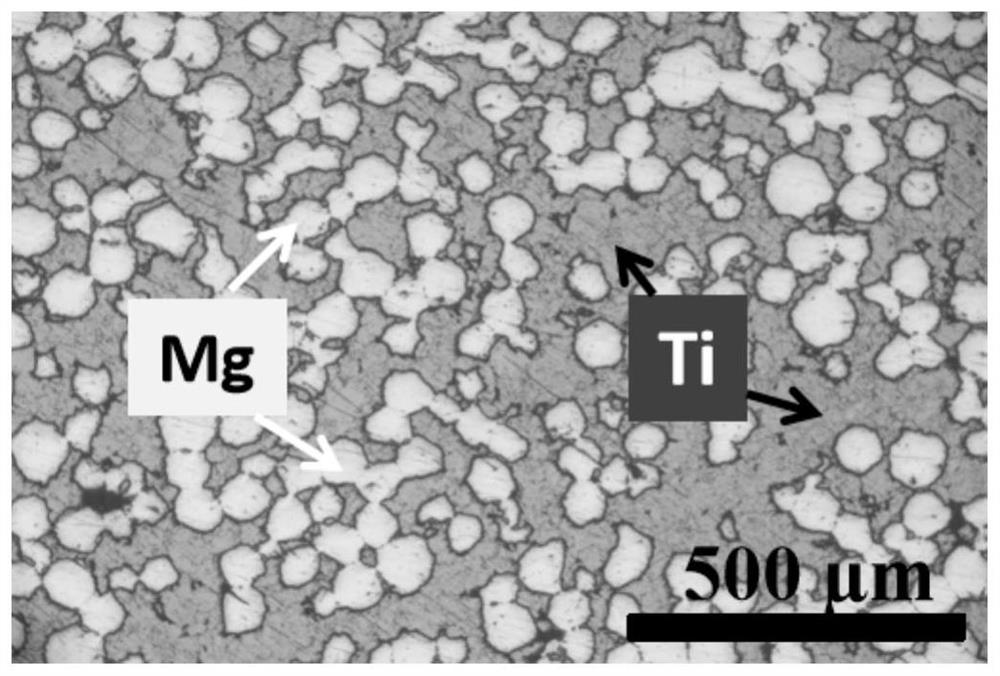

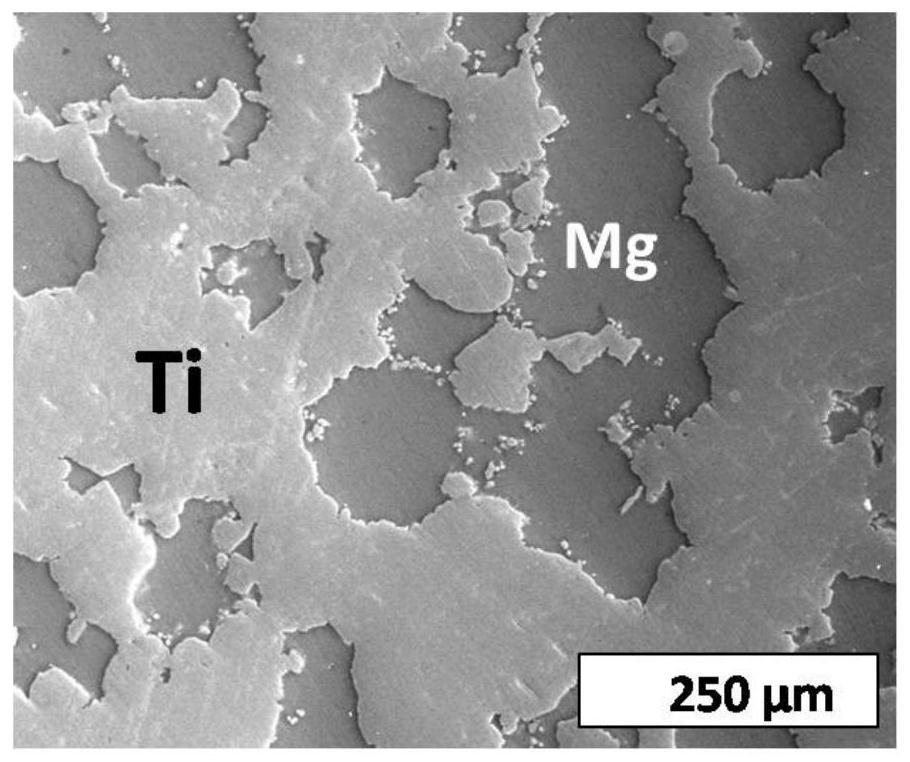

Preparation method for titanium-magnesium double-metal composite of double-communication netted structure

ActiveCN106670464APromote bone growthExcellent osteoinductive propertiesLow elastic modulusStress shielding

The invention relates to a preparation method for a titanium-magnesium double-metal composite of a double-communication netted structure to solve the problems of stress shielding and poor bioactivity caused by a high elasticity modulus of traditional biochemical metal materials such as stainless steel and a titanium alloy. The preparation method comprises the steps that a magnesium alloy with a low elasticity modulus and good osteogenic induction performance is permeated into porous titanium with a low elasticity modulus through a permeation method after being melted; and the titanium-magnesium double-metal composite of the double-communication netted structure is prepared through cooling. The preparation method is used for preparing the titanium-magnesium double-metal composite of the double-communication netted structure.

Owner:HARBIN INST OF TECH

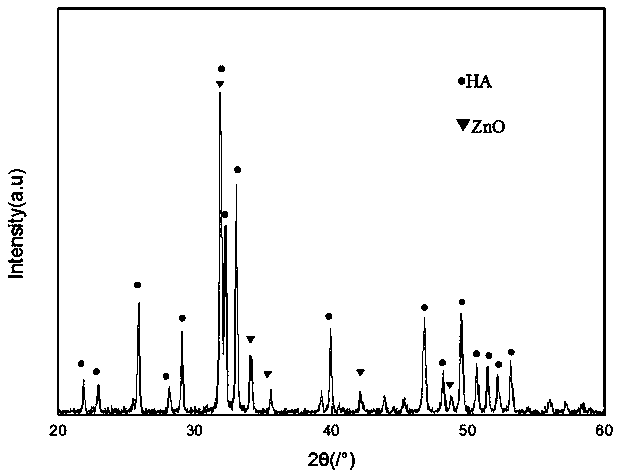

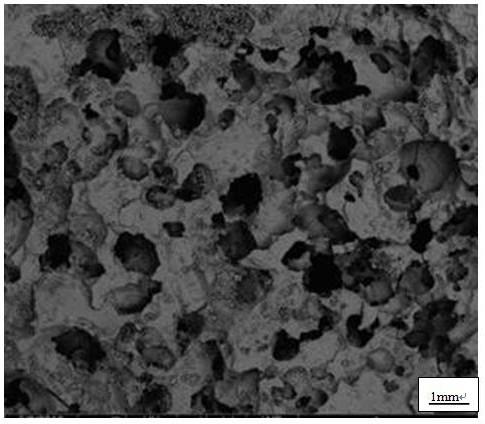

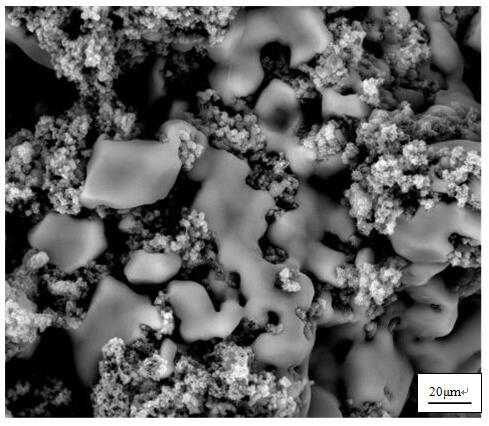

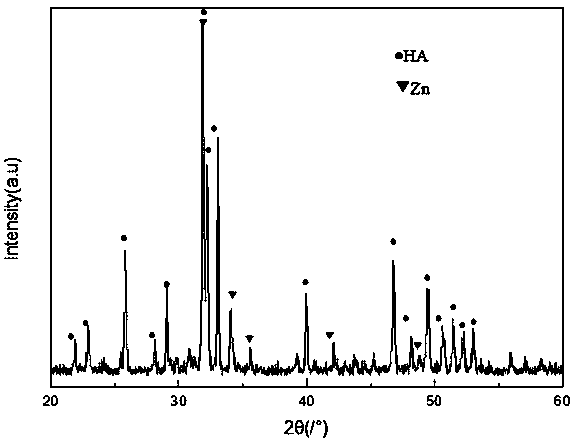

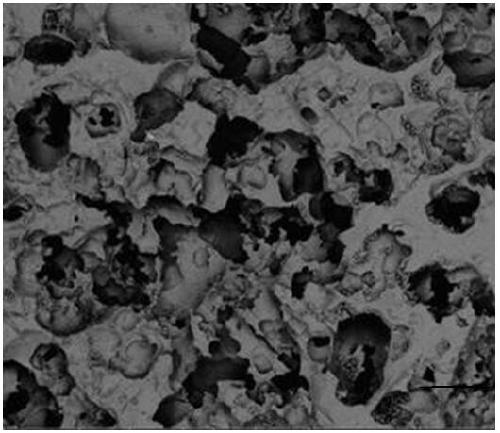

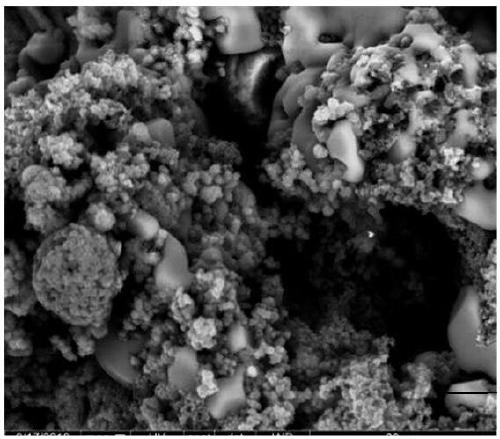

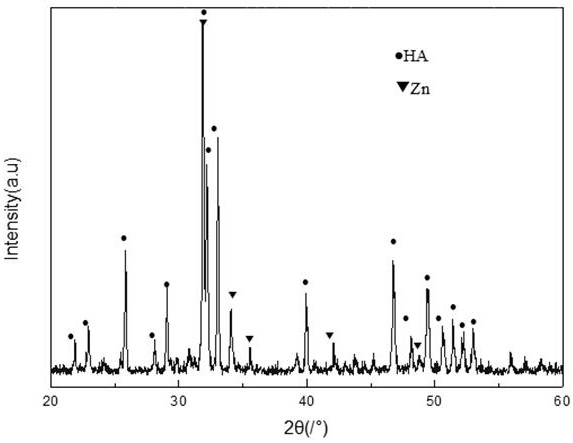

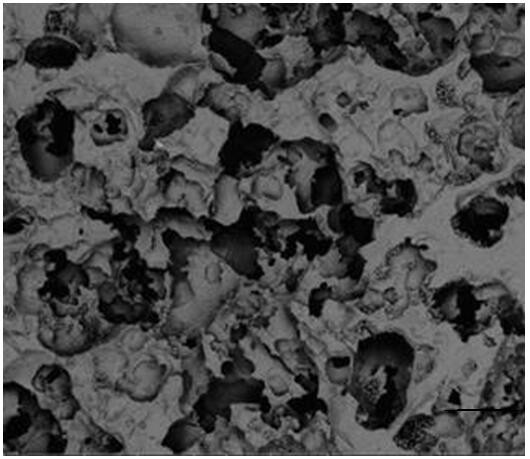

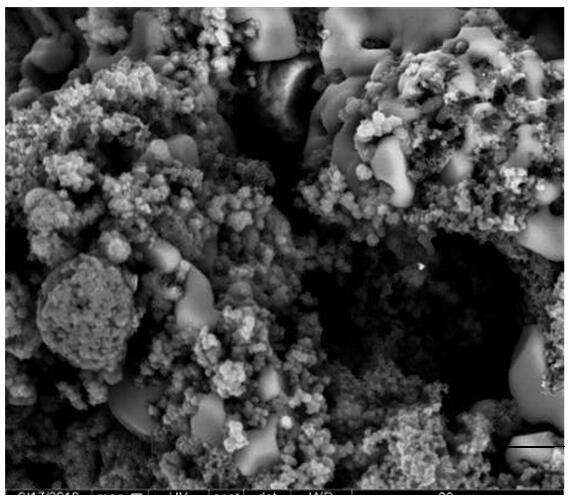

Preparation method of nano-zinc oxide-doped hydroxyapatite porous ceramic

ActiveCN110054491APure ingredientsAvoid churnPharmaceutical delivery mechanismTissue regenerationApatiteZno nanoparticles

The invention relates to a preparation method of a nano-zinc oxide-doped hydroxyapatite porous ceramic and belongs to the technical field of preparation of biomedical materials. The preparation methodtakes nano-zinc powder and hydroxyapatite powder as the raw materials and comprises weighing out ZnO and HA (hydroxyapatite) at a weight ratio of 1-7%:99%-93%, performing ball milling to obtain composite powder, uniformly mixing and pressing the composite powder and a pore forming agent of ammonium bicarbonate to obtain a blank, and then preparing the nano-zinc oxide-doped hydroxyapatite porous ceramic through a spark plasma sintering method. The prepared nano-zinc oxide-doped hydroxyapatite porous ceramic is pure in composition and achieves a controllable porosity of 40-70%, and added nano-zinc oxide can improve the osteogenic induction capacity of the nano-zinc oxide-doped hydroxyapatite porous ceramic and further improve the bone-forming capacity of parts around an implanted part; by controlling the porosity of the nano-zinc oxide-doped hydroxyapatite porous ceramic, the preparation method can prepare biological ceramics which meet different requirements and are applied to bone scaffold, filling and repair materials.

Owner:KUNMING UNIV OF SCI & TECH

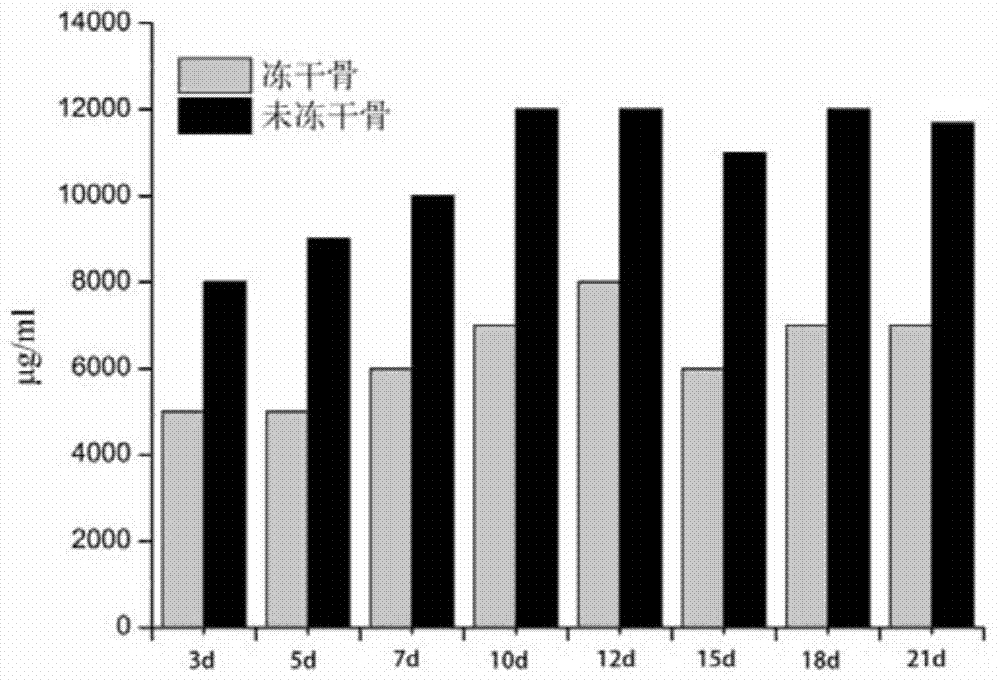

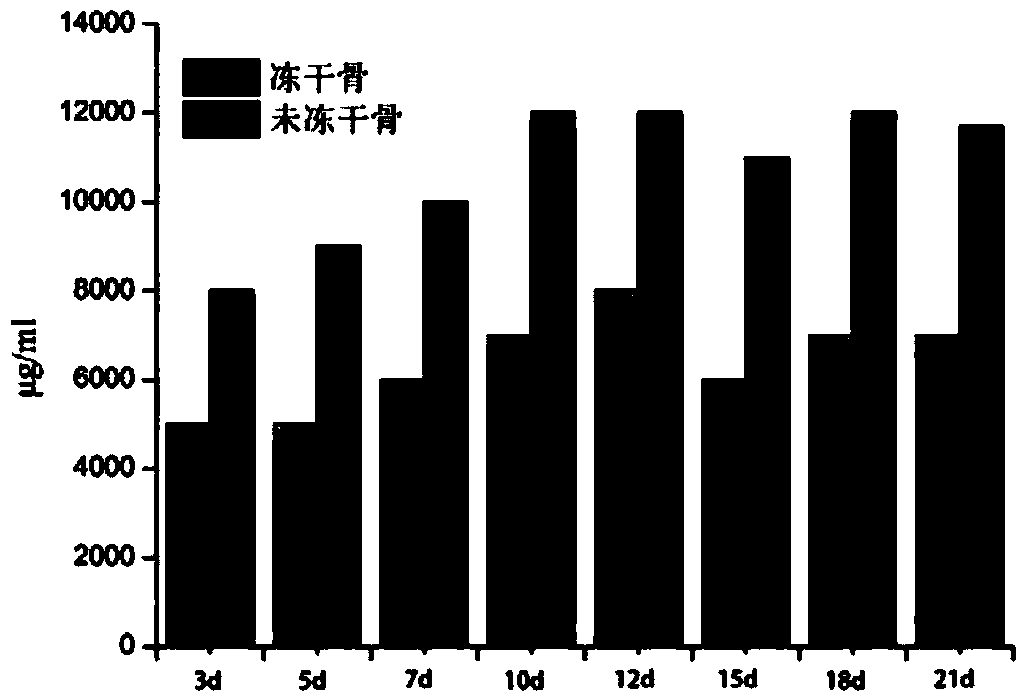

Preparation method of bovine cortical bone grafting material

The invention discloses a method for preparing a bovine cortical bone grafting material, comprising the following steps: degreasing and decalcifying a cleaned bovine cortical bone block, immersing the bovine cortical bone block in an inhibitor of a bone morphogenetic protein degrading enzyme, then performing deproteinization, and finally obtaining the bovine cortical bone grafting material by freezing and drying. The preparation method has the advantages of simple steps, wide material source, low cost, low antigenicity of the obtained bone grafting material, strong bone formation inducibility, high biomechanical strength.

Owner:胡懿郃

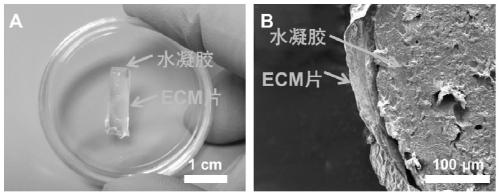

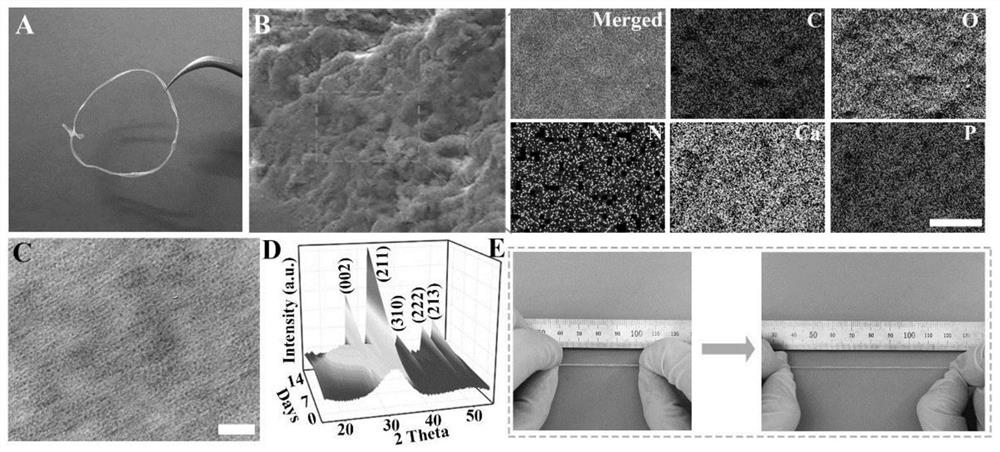

Bionic periosteum, periosteum-bone substitute and preparation method

PendingCN111518755APromote regenerationRepair defectCell culture supports/coatingSkeletal/connective tissue cellsCell-Extracellular MatrixSomatic cell

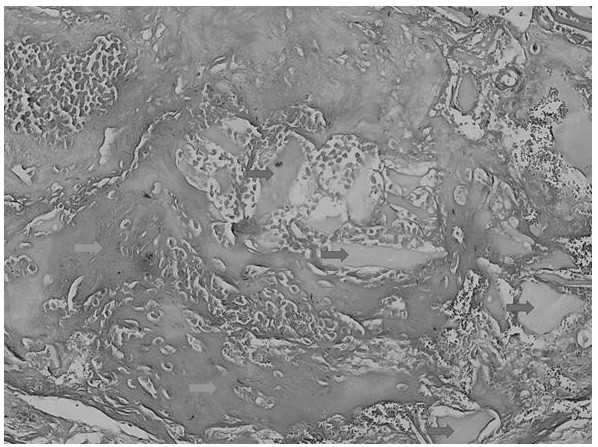

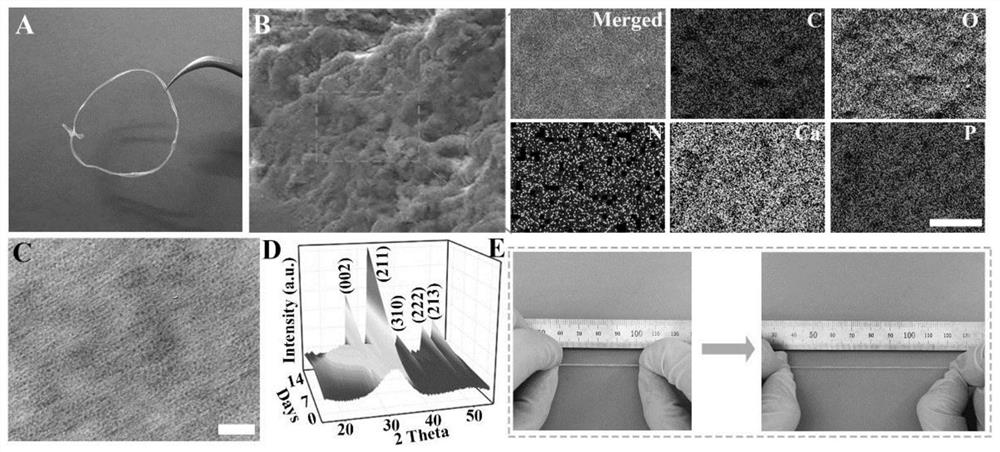

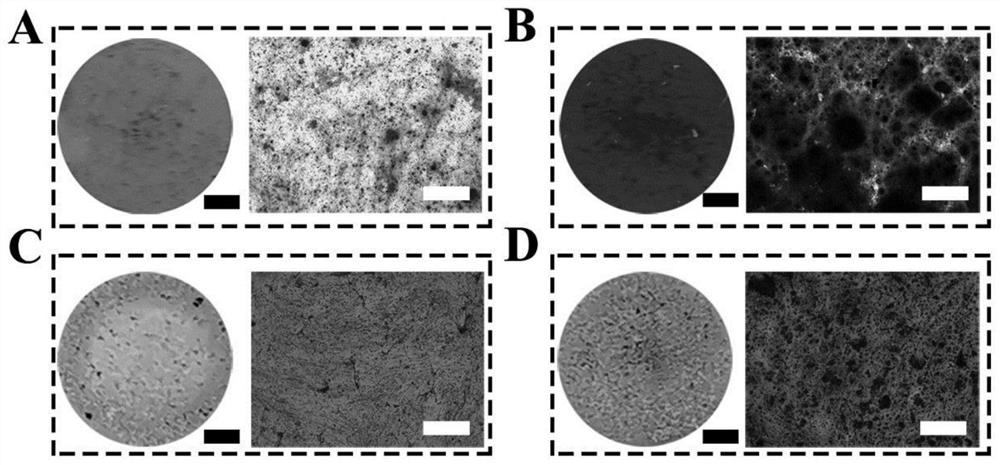

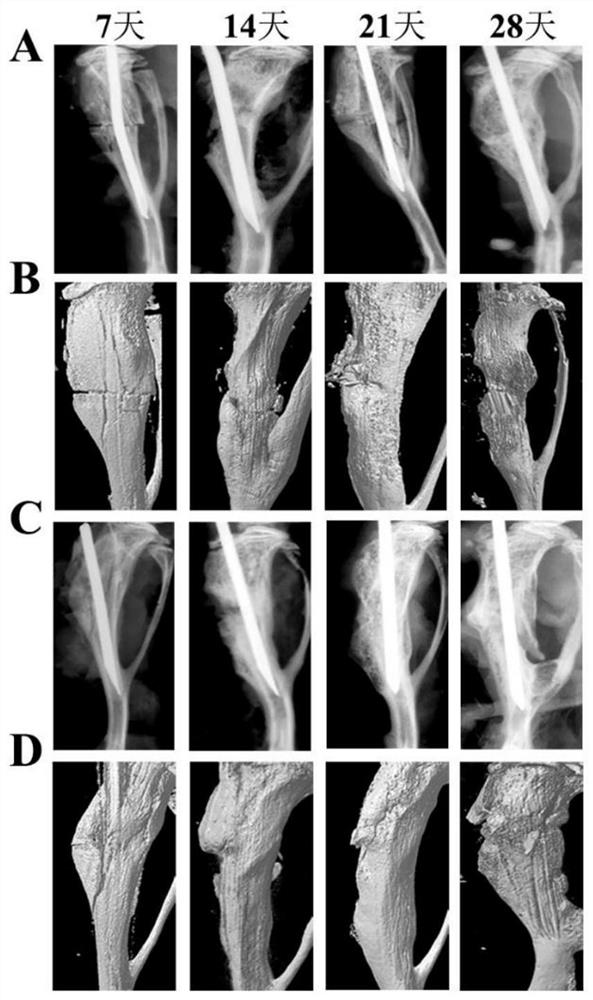

The invention discloses a bionic periosteum for repairing a segmental bone defect, a periosteum-bone substitute and a preparation method. The bionic periosteum is prepared by culturing osteogenic precursor cells on the surface of polydimethylsiloxane, and removing the cells after forming a cell sheet to obtain an extracellular matrix (ECM) sheet. The bionic periosteum winds the surface of a degradable bone scaffold material to form the periosteum-bone substitute. The prepared osteogenic precursor cell-derived ECM sheet not only has biological activity, but also shows a bone induction effect invitro and in vivo. In addition, the ECM sheet has a chemotactic effect on mesenchymal stem cells. Through combination of the cell-derived ECM sheet and the degradable bone scaffold material, an existing membrane induction technique for repairing the large-area segmental bone defect in clinic can be improved; the preparation method is simple; and the periosteum-bone substitute can be used as an excellent periosteum-bone substitute material.

Owner:SUZHOU UNIV

Injectable bone grafting material, preparation method and use method

ActiveCN105641748AGood bone conduction and bone formation abilityLow antigenicityPharmaceutical delivery mechanismTissue regenerationInjectable boneIntervertebral space

The invention relates to the technical field of medical bone repair materials, in particular to an injectable bone grafting material, a preparation method and a use method. The bone grafting material is characterized by being prepared from, by weight, 6-10 parts of decalcified bone matrix, 0.8-1.5 parts of PRP, 0.5-2 parts of autologous hemocyte growth factors, 0.5-2 parts of Radix Salviae Miltiorrhizae injection, 0.05-0.2 part of doxycycline and 0.001-0.005 part of scopolamine, decalcified bone matrix, PRP, autologous hemocyte growth factors, doxycycline and scopolamine are mixed in real time during surgery, the mixture is arranged in a 10 ml syringe and compounded into an injectable mixture, and the bone grafting material is injected in an intraoperative bone defect part or the part (such as an intervertebral space) needing bone fusion enhancement, and has the advantages of being good in union effect, resistant to infection, high in osteogenic induction capacity, high in osteogenic strength, and the like.

Owner:THE WENDENG OSTEOPATH HOSPITAL

Preparation method of nano zinc loaded hydroxyapatite porous bioceramic

The invention discloses a preparation method of nano zinc loaded hydroxyapatite porous bioceramic and belongs to the technical field of biomecial material preparation. The method includes: weighing nano hydroxyapatite (99-93%) and nano zinc powder (1-7%) according to a mass ratio, ball-milling to obtain compound powder, mixing the compound powder with a pore former ammonium hydrogen carbonate, pressing after well mixing to obtain a blank, and utilizing discharging plasma sintering technology to prepare the nano zinc loaded hydroxyapatite porous bioceramic. The porous bioceramic prepared by themethod is uniform and pure in composition, porosity is controllable between 40-70%, compressive strength is 82-162Mpa, and pore size is 50-600um; by adding zinc, osteogenic inducing ability of the porous bioceramic is improved remarkably, and degradation rate is matched with osteogenesis rate; the porous bioceramic is suitable for bone stents and filling and repairing materials.

Owner:KUNMING UNIV OF SCI & TECH

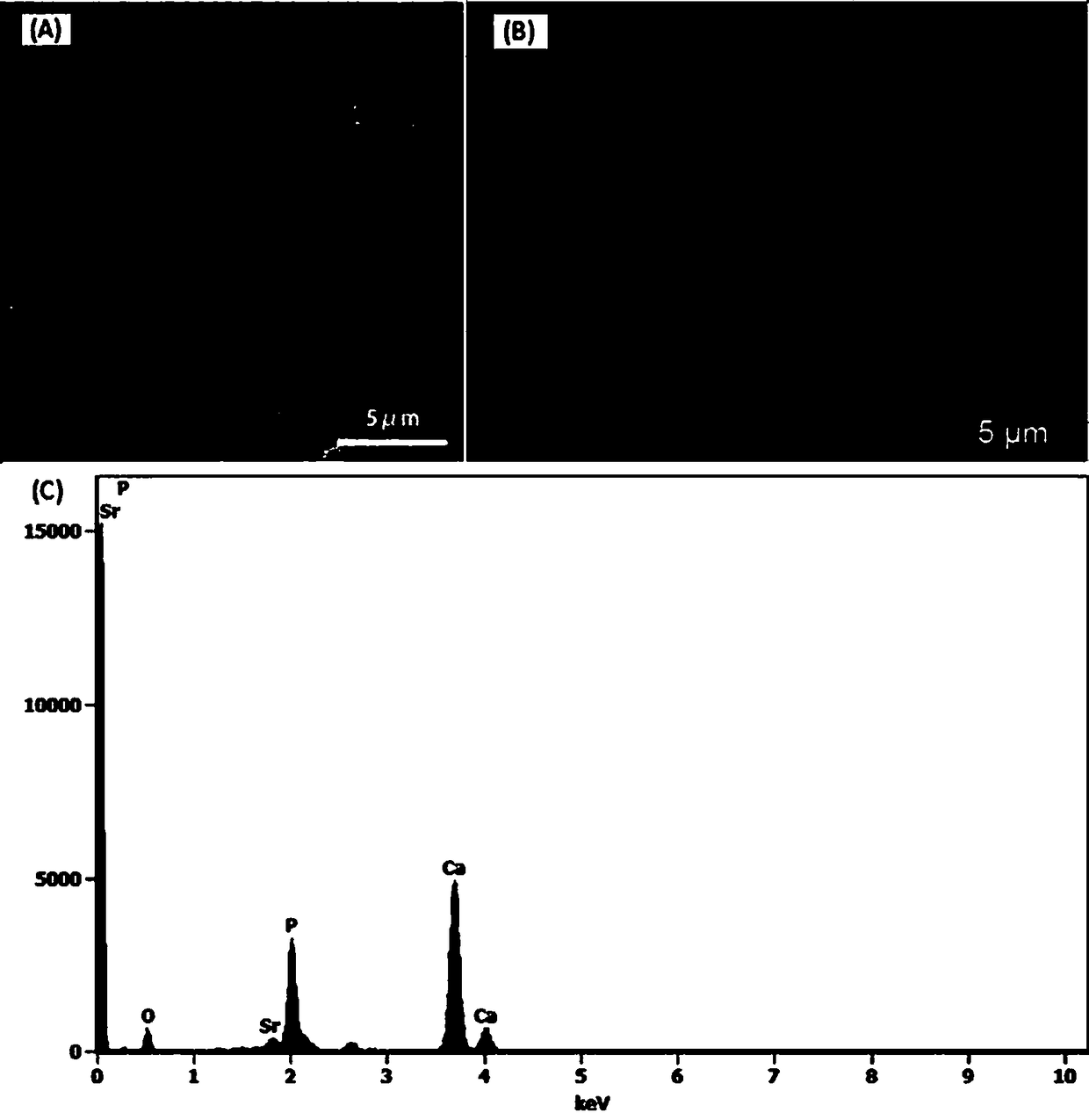

Method for preparing strontium-containing biological composite material based bone bracket

InactiveCN109279885AGood biocompatibilityAppropriate degradation rateAdditive manufacturing apparatusCeramic shaping apparatusChemistryRepair material

The invention relates to the technical field of 3D printing and particularly relates to a method for preparing a strontium-containing biological composite material based bone bracket. The method comprises the specific steps: (1) preparing a sodium alginate solution; (2) adding biological inorganic material powder into the sodium alginate solution in multiple times, and carrying out homogeneous dispersion, so as to obtain a biological inorganic material-sodium alginate suspension; and (3) subjecting the biological inorganic material-sodium alginate suspension obtained in the step (2) to crosslinking for 1min or more with a solution containing strontium ions while controlling the crosslinking temperature to 4 DEG C to 80 DEG C, thereby obtaining a strontium-containing biological composite material. According to the strontium-containing biological composite material and the preparation method therefor, provided by the invention, the porous strontium-containing biological composite material for bone repair has good biocompatibility, appropriate degradation rate and good osteogenesis induction capability, the clinical requirements of bone-defection regeneration repair materials on performance are met, and the clinical application of the strontium-containing biological composite material is promoted.

Owner:NANCHANG UNIV

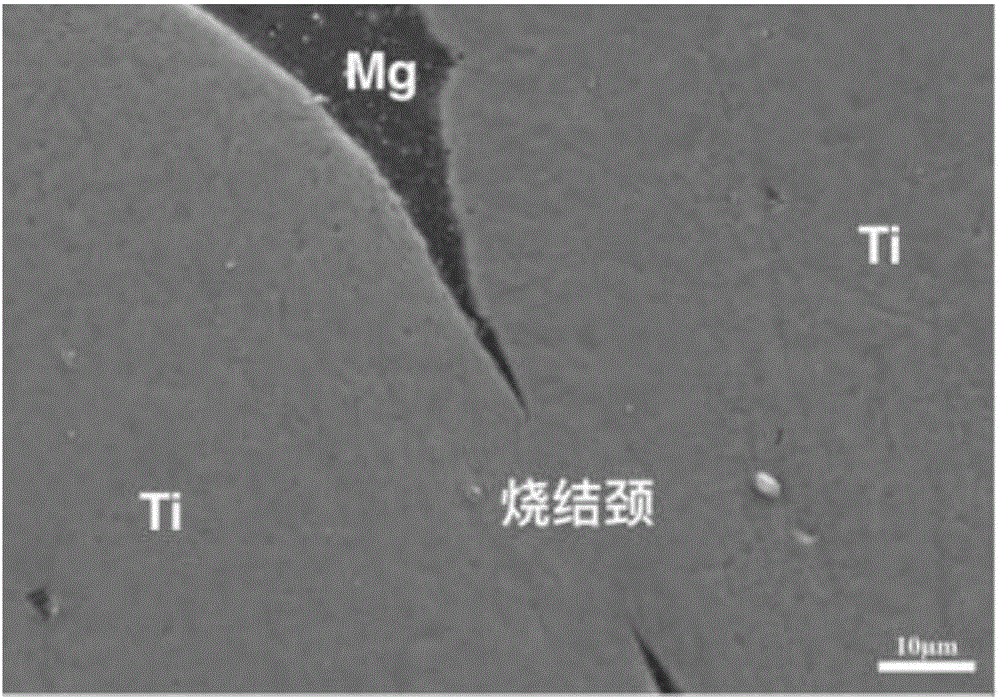

A kind of preparation method of double connected network structure titanium-magnesium bimetallic composite material

ActiveCN106670464BLow elastic modulusExcellent osteoinductive propertiesNetwork structureStress shielding

The invention relates to a preparation method for a titanium-magnesium double-metal composite of a double-communication netted structure to solve the problems of stress shielding and poor bioactivity caused by a high elasticity modulus of traditional biochemical metal materials such as stainless steel and a titanium alloy. The preparation method comprises the steps that a magnesium alloy with a low elasticity modulus and good osteogenic induction performance is permeated into porous titanium with a low elasticity modulus through a permeation method after being melted; and the titanium-magnesium double-metal composite of the double-communication netted structure is prepared through cooling. The preparation method is used for preparing the titanium-magnesium double-metal composite of the double-communication netted structure.

Owner:HARBIN INST OF TECH

Injectable strengthened phosphate lime/hydrogel microcapsule tissue engineering bone as well as preparation method and application thereof

The invention discloses an injectable strengthened phosphate lime / hydrogel microcapsule tissue engineering bone which is prepared from the following components in percentage by weight: 20-75% of calcium phosphate cement, 20-75% of chitosan, 1-10% of PLGA electric spin and 3-155 of hUCMSCs hydrogel microcapsule. The invention also discloses a preparation method of the tissue engineering bone and application of the tissue engineering bone as a bone defect repairing material. The tissue engineering bone not only maintains original good biocompatibility and osteogenesis inducing property of phosphate lime, but also obviously improved mechanical properties and capability for carrying seed cells. The tissue engineering bone can be used for treating bone defect or bone deficiency caused by various diseases and has the characteristics of easy operation, convenient molding, maximum wound reduction, operation difficulty reduction, patient pain alleviation, less infection danger, less scar formation and the like.

Owner:赵亮

Tissue-engineered alveolar bone tissue and preparation method thereof

InactiveCN112076349APromote mineralizationImprove plasticityAdditive manufacturing apparatusArtificial cell constructsCell-Extracellular MatrixBone tissue

The invention discloses a tissue-engineered alveolar bone tissue and a preparation method thereof. The tissue-engineered alveolar bone tissue comprises a cell polymer containing seed cells and an extracellular matrix and a scaffold material for promoting bone formation through 3D customization. The tissue-engineered alveolar bone tissue can form a new alveolar bone tissue structure in vivo to recover the horizontal or vertical bone height of the alveolar bone. The tissue-engineered alveolar bone tissue has advantages of simple preparation method, shapeability, availability of a variety of seedcells, a large amount of extracellular matrix, and short in vitro culture and preparation period. Compared with other types of alveolar bone technologies existing at present, the tissue-engineered alveolar bone tissue has better biological activity and good biological safety, and can remarkably shorten time for new bone formation.

Owner:西安交通大学口腔医院

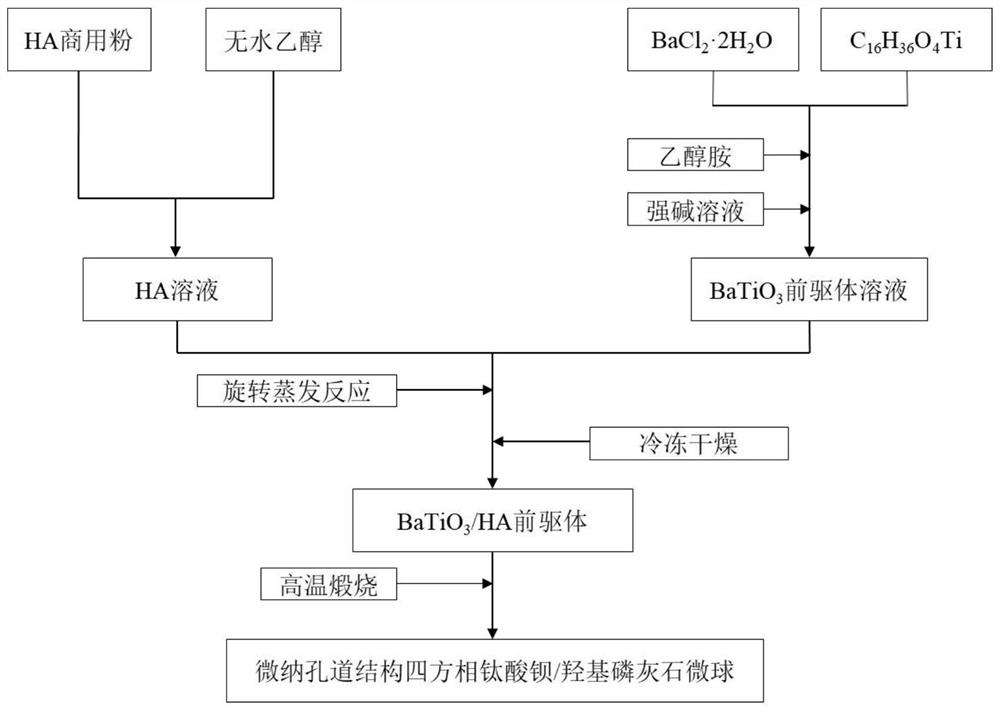

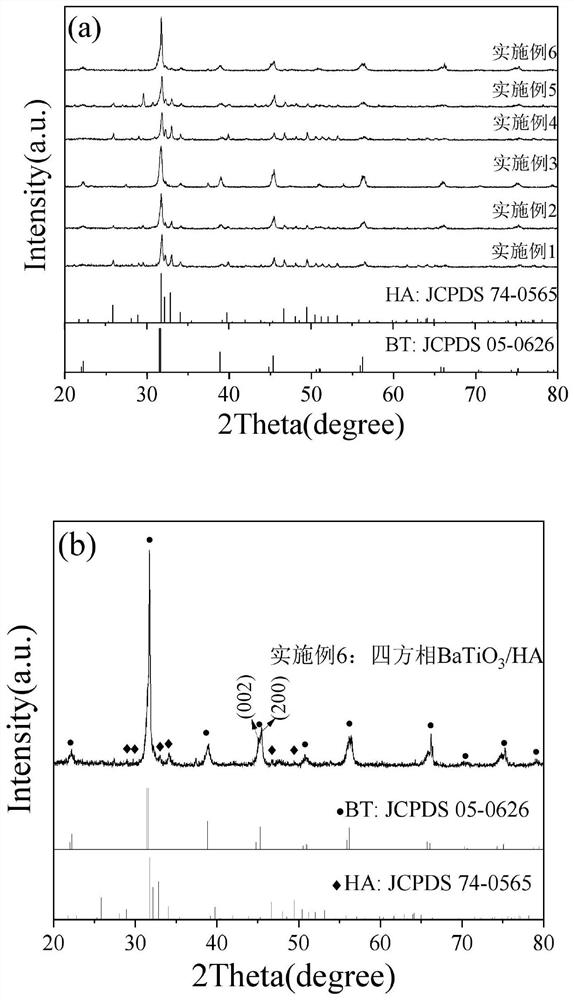

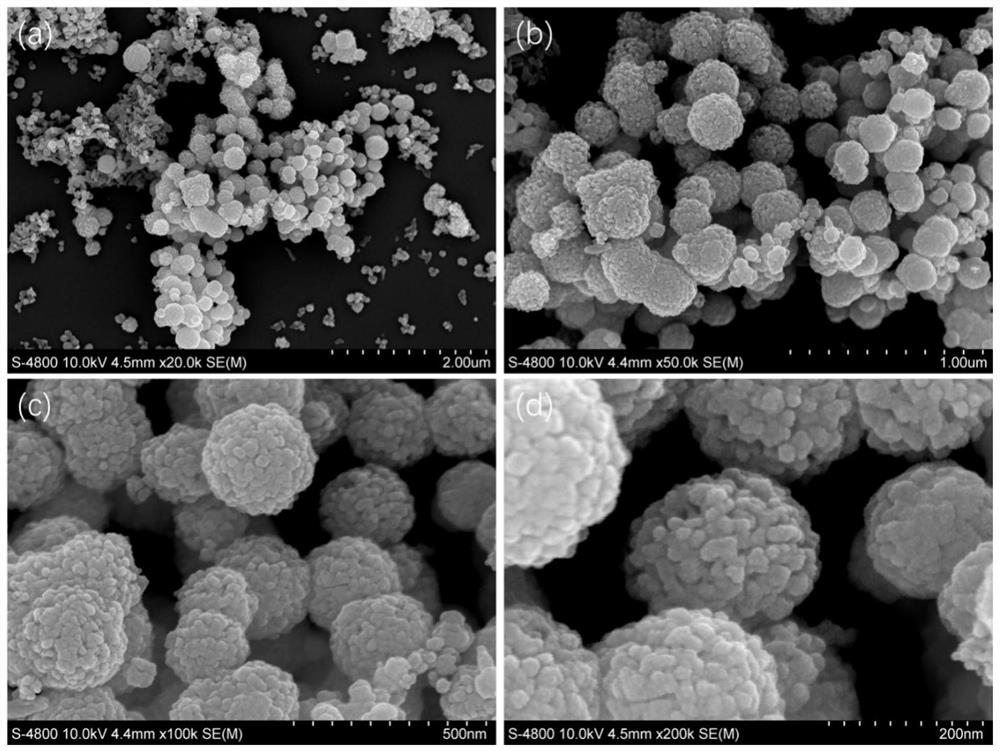

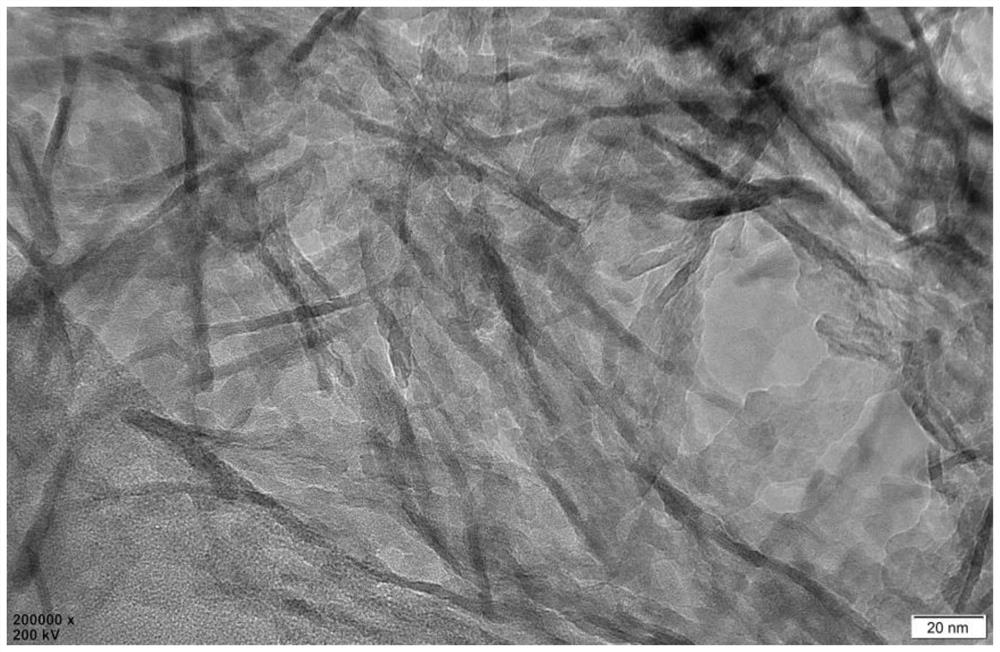

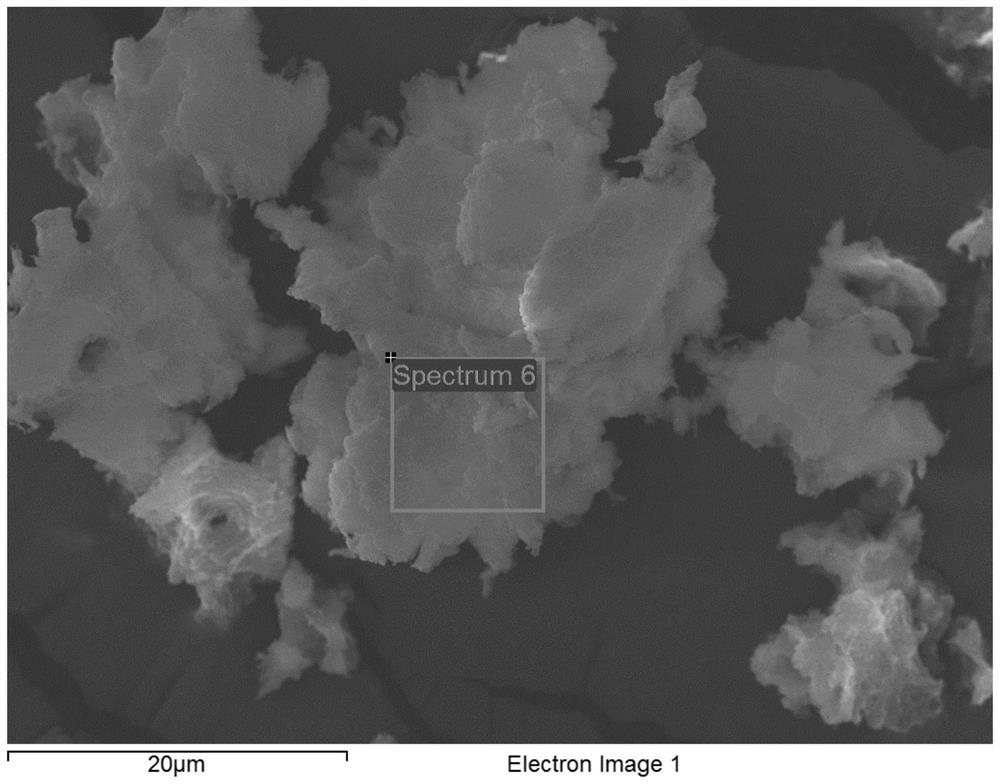

Micro-nano channel structure tetragonal phase batio 3 The preparation method of /ha hollow microspheres

ActiveCN113372131BPiezoelectric activityBiologically activeInorganic non-active ingredientsGranular deliveryInorganic saltsFluid phase

The invention discloses a tetragonal phase BaTiO with micro-nano channel structure 3 The invention discloses a method for preparing / HA hollow microspheres, belonging to the technical field of bioceramic materials. In this method, the BaTiO 3 Complete the atomic-scale mixing with HA and fix it in the form of a liquid precursor, and then the precursor powder after rotary evaporation is subjected to liquid nitrogen wet freeze molding, and after freeze-drying, it is successfully prepared through a high-temperature calcination process. Tetragonal BaTiO 3 / HA microspheres. In the synthesis process of the present invention, common inorganic salts and simple reagents are mainly used, and the cost is low, simple and easy, and the repeatability is good. The synthesized micro-nano channel structure tetragonal BaTiO 3 / HA microspheres have high performance and good stability, are suitable for large-scale production, and can promote the commercialization of bioceramic materials.

Owner:XIAN UNIV OF TECH

A magnetic magnesium-loaded artificial bone and a method for preparing a magnetic magnesium-loaded artificial bone using 3D printing

ActiveCN110384828BImprove biological activityPromote degradationAdditive manufacturing apparatusTissue regenerationSelective laser sinteringComputer printing

The invention discloses a magnetic magnesium-loaded artificial bone and a method for preparing the magnetic magnesium-loaded artificial bone by 3D printing. The artificial bone includes the following components in parts by weight: PLA 6-10, β‑TCP 0.8-1.2, MgSO 4 0.3~0.7, Fe 3 o 4 0.3~0.7. The method uses computer-aided design software to carry out bionic design on the model of the bone scaffold, and then according to the principle of component bionics, PLA, β-TCP, MgSO 4 , Fe 3 o 4 The four raw materials were mixed according to the ratio of 8:1:0.5:0.5, and the obtained powder was centrifuged, washed, dried, and ground to obtain a composite powder. The obtained composite powder was sintered with a 3D printer to prepare a magnetic magnesium-loaded artificial bone.

Owner:THE SECOND XIANGYA HOSPITAL OF CENT SOUTH UNIV

Active element doped mineralized collagen nanofiber and preparation method thereof

PendingCN113913961AAchieve bone regenerationGood bone compatibilityMonocomponent protein artificial filamentArtifical filament manufactureChemistryHydroxyapatite crystal

The invention provides active element doped mineralized collagen nanofiber and a preparation method thereof. The mineralized collagen nanofiber is composed of collagen fiber and needle-like hydroxyapatite crystals; and part of calcium elements in crystal lattices of the hydroxyapatite crystals are substituted by positive ions containing active elements, and / or, part of phosphate radicals in the crystal lattices of the hydroxyapatite crystals are substituted by negative ions containing active elements. The preparation process is simple and easy to implement, and a product obtained by compounding the obtained mineralized collagen nanofiber and a high polymer material (collagen, PCL and the like) can obviously improve the strength and rigidity of an original high polymer material. In addition, a plurality of active element doping schemes are adopted to meet the requirement of a tumor inhibition, anti-infection and immunoregulation cell microenvironment provided by material degradation in a bone repair process. A good thought is provided for design and development of the high-molecular bone repair material, and greater economic benefits are brought to human health and social development.

Owner:TSINGHUA UNIV

A kind of small size calcium phosphate fiber and its preparation method and application

ActiveCN113577103BEasy to operateRaw materials are easy to getInorganic phosphorous active ingredientsSkeletal disorderFiberCalcium biphosphate

Owner:ZHEJIANG UNIV

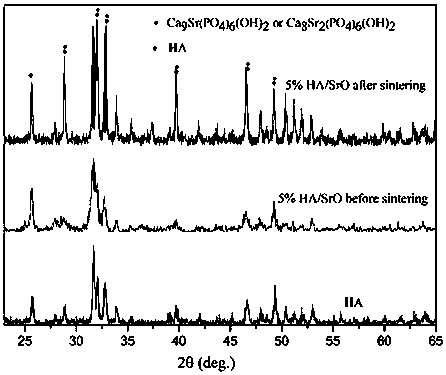

Preparation method of a porous hydroxyapatite/strontium oxide composite bone repair material

ActiveCN105712736BNo decompositionGood biocompatibilityCeramic shaping apparatusTissue regenerationPorosityBall mill

The invention relates to a preparation method of a porous hydroxyapatite and strontium oxide composite bone repair material, and belongs to the technical field of biomedical material preparation. The method comprises the steps that 88%-99% by mass of hydroxyapatite and 12%-1% by mass of strontium oxide ceramic powder are weighed and ball-milled, and mixed powder is obtained; 40%-70% by mass of the mixed powder and 60%-30% by mass of ammonium bicarbonate pore-forming agent powder are mixed to be uniform and mechanically pressed into a block pressed blank; the pressed blank is put into a graphite mold, then the graphite mold is put into a discharging plasma sintering furnace for sintering, the sintered mold is naturally cooled to room temperature along with the furnace, demolding is conducted, and the porous hydroxyapatite and strontium oxide composite bone repair material is obtained. According to the porous hydroxyapatite and strontium oxide composite bone repair material prepared through the preparation method, any binding agent and templating agent do not need to be added, the components are pure, harmful impurities do not exist, the porosity is controllable between 20% and 50%, the degradation rate is appropriate, good osteogenic induction capacity is achieved, the technology is simple and easy to carry out, and the porous hydroxyapatite and strontium oxide composite bone repair material can be used for a bone defect repair material for hard tissue regeneration or reconstruction of organisms.

Owner:KUNMING UNIV OF SCI & TECH +1

A slow-release antibacterial composite bone graft material and its preparation method

ActiveCN107469155BLong local release timeImprove the bactericidal effectAntibacterial agentsInorganic active ingredientsMedicineMicrosphere

The invention discloses a sustained-release antibacterial compound bone grafting material and a preparation method thereof. The sustained-release antibacterial compound bone grafting material is mainly prepared by mixing nanosilver / TMC-207 sustained release microspheres, nano-hydroxyapatite and calcium phosphate cement powder. The preparation method comprises the following steps: firstly, preparing the nanosilver / TMC-207 sustained release microspheres by an O / O emulsion-solvent evaporation method, wherein PLGA is used as a carrier material; secondly, mixing the nanosilver / TMC-207 sustained release microspheres, the nano-hydroxyapatite and the calcium phosphate cement powder, and blending an obtained mixture with deionized water to obtain paste; setting and drying the paste to obtain the slow-release antibacterial compound bone grafting material. The sustained-release antibacterial compound bone grafting material disclosed by the invention has the advantages of long local drug release time, obvious sterilizing effect and high bone repairing capability. The preparation method has the advantages of being simple and convenient to operate and lower in cost.

Owner:XIANGYA HOSPITAL CENT SOUTH UNIV

A kind of injectable bone graft material and preparation method thereof

ActiveCN105641748BGood bone conduction and bone formation abilityLow antigenicityPharmaceutical delivery mechanismTissue regenerationInjectable boneIntervertebral space

The invention relates to the technical field of medical bone repair materials, in particular to an injectable bone grafting material, a preparation method and a use method. The bone grafting material is characterized by being prepared from, by weight, 6-10 parts of decalcified bone matrix, 0.8-1.5 parts of PRP, 0.5-2 parts of autologous hemocyte growth factors, 0.5-2 parts of Radix Salviae Miltiorrhizae injection, 0.05-0.2 part of doxycycline and 0.001-0.005 part of scopolamine, decalcified bone matrix, PRP, autologous hemocyte growth factors, doxycycline and scopolamine are mixed in real time during surgery, the mixture is arranged in a 10 ml syringe and compounded into an injectable mixture, and the bone grafting material is injected in an intraoperative bone defect part or the part (such as an intervertebral space) needing bone fusion enhancement, and has the advantages of being good in union effect, resistant to infection, high in osteogenic induction capacity, high in osteogenic strength, and the like.

Owner:THE WENDENG OSTEOPATH HOSPITAL

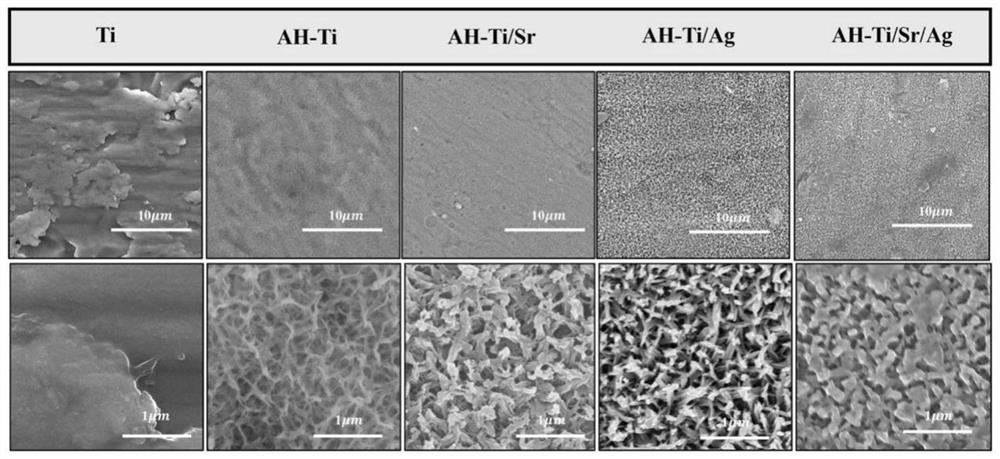

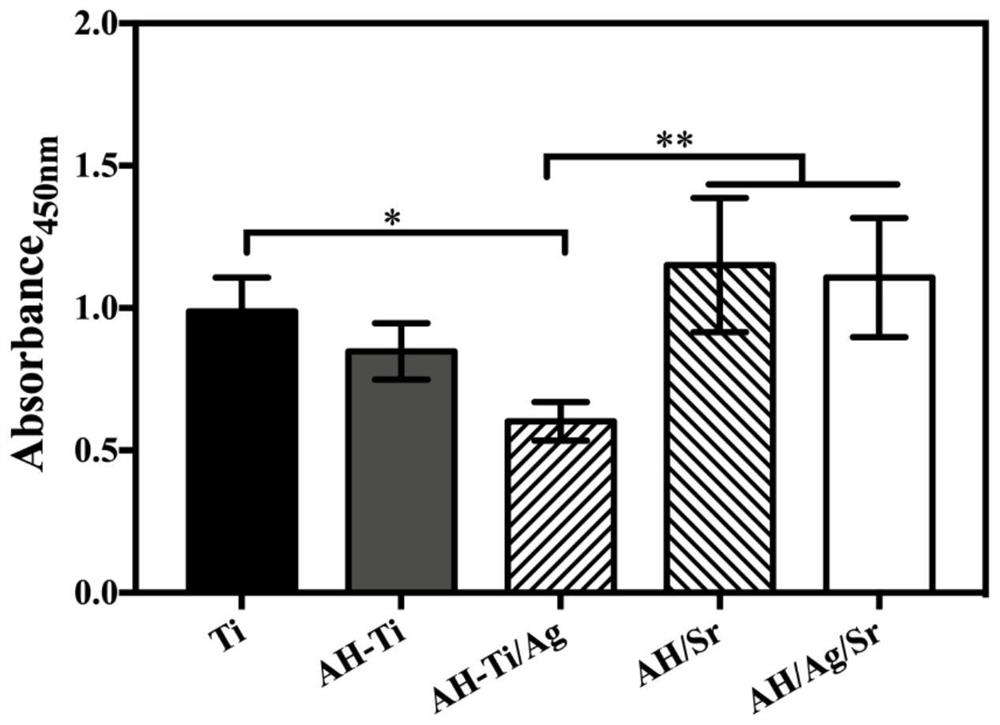

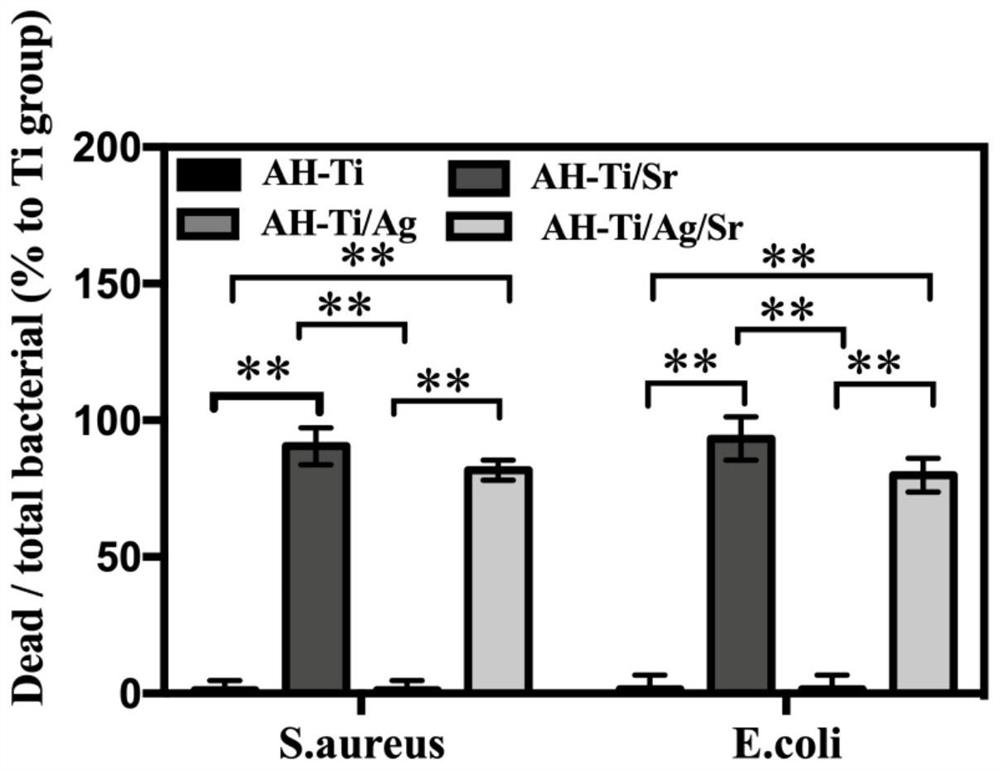

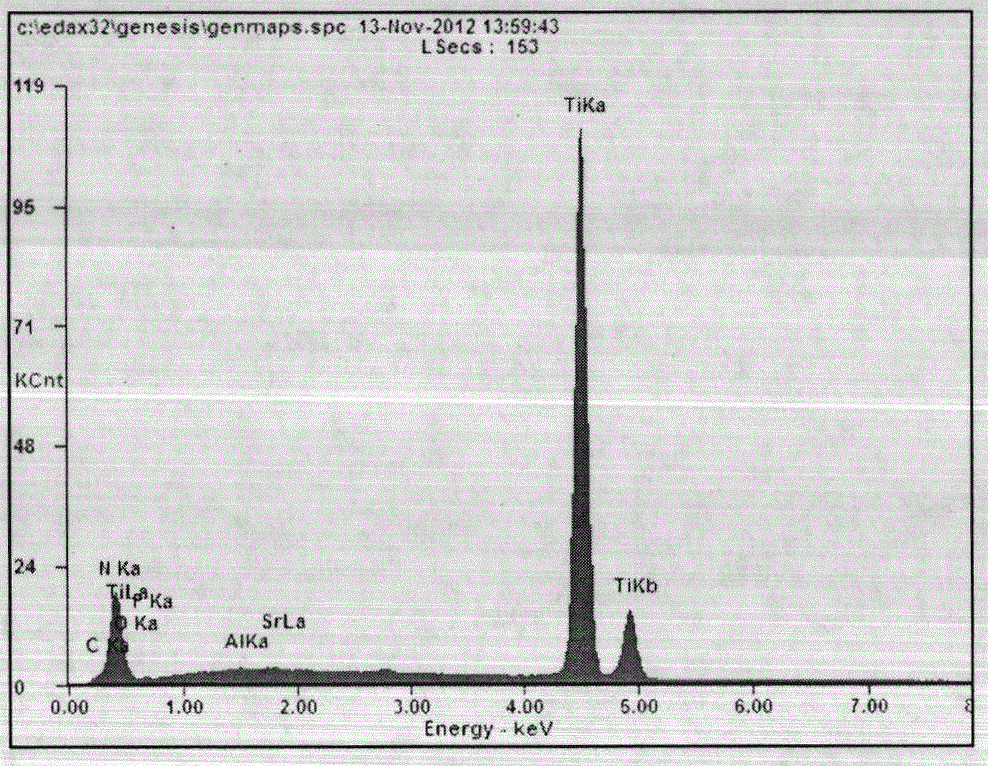

Preparation method of strontium/silver nano-coating modified bone bionic titanium implant

InactiveCN111821506APromote formationImprove osseointegrationVacuum evaporation coatingPharmaceutical delivery mechanismMatrix damageTitanium implant

The invention discloses a preparation method of a strontium / silver nano-coating modified bone bionic titanium implant. The method comprises the following steps of carrying out modification and hot alkali treatment on the surface of a titanium material by a magnetron sputtering method, and sequentially coating the surface with a nano-sized two-layer film containing silver element and strontium element, thereby obtaining the bone bionic titanium implant with good biocompatibility, osteogenic induction promoting function and good antibacterial property. The magnetron sputtering method provided bythe invention has the advantages of simple process method, small matrix damage and the like.

Owner:温州医科大学附属口腔医院

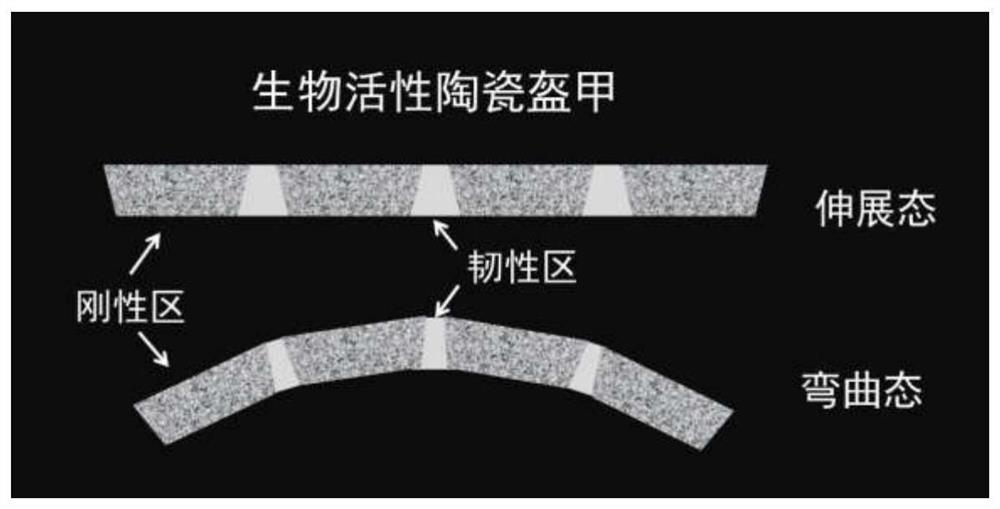

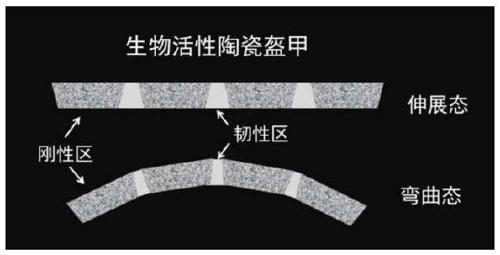

Mechanically adaptable bioactive ceramic armor and its preparation method

ActiveCN111346260BGuaranteed healthy growthGood osteoinductivityTissue regenerationProsthesisSkull InjuriesRepair tissue

The invention provides a bioactive ceramic armor with mechanical adaptability and a preparation method thereof. Chitosan, polycaprolactone and hydroxyapatite are used as rigid ceramic units, and polycaprolactone is used as a flexible joint connecting the ceramic units. Partly, through casting technology, in situ biomimetic construction of rigid and flexible bioactive ceramic armor materials. The biologically active armor material prepared by the invention not only has certain mechanical adaptability, but also has good biological activity. Facing the repair of skull injuries in young children, skull repair in complex dynamic mechanical environments such as intracranial hypertension, by implanting this kind of ceramic armor, it can adaptively match the mechanical stretching requirements, and at the same time induce the healthy growth of defective skull tissue to achieve normal repair tissue. form and function.

Owner:SICHUAN UNIV

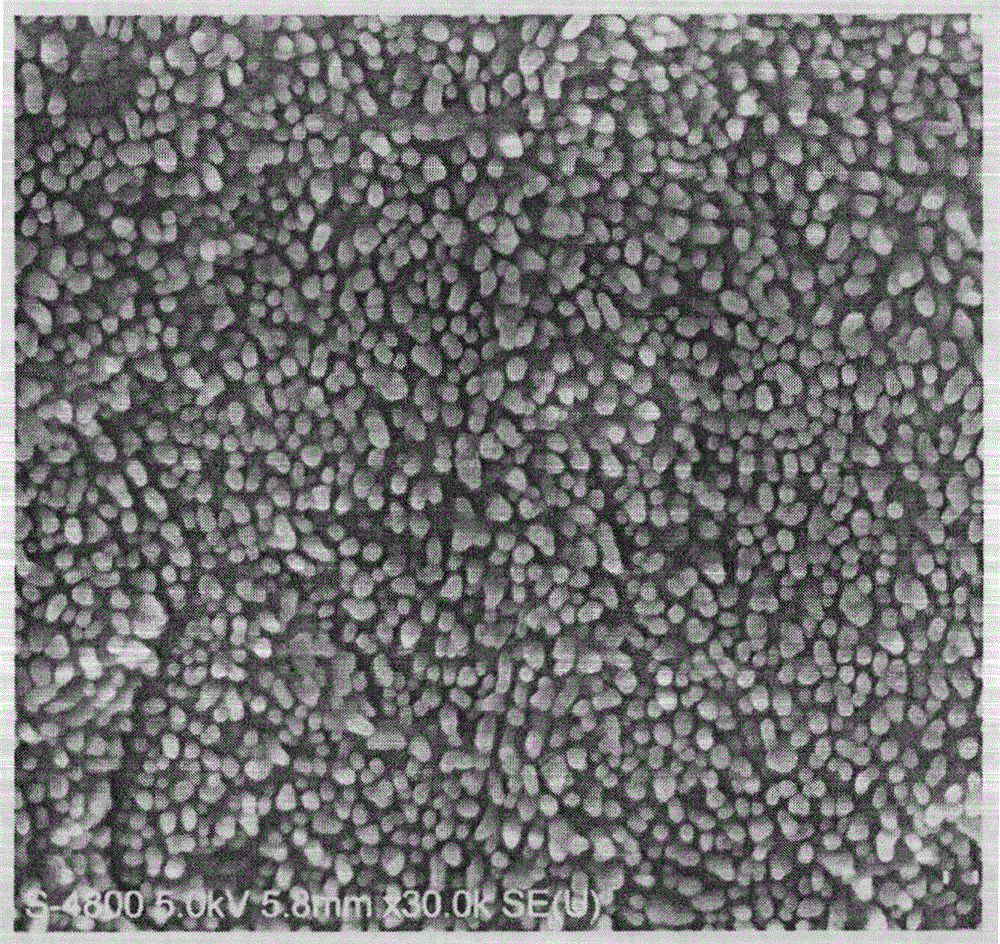

Preparation method of anti-osteoporosis bone implant micro/nano biomimetic coating

ActiveCN103341210BBionic effectSolve the problem of insufficient bond strengthVacuum evaporation coatingSputtering coatingAcid etchingBiomimetic coating

The invention discloses a preparation method of an anti-osteoporotic and high-bonding-strength micro / nano biomimetic coating of a bone implant. The method comprises: (1) putting the implant into a hydrofluoric acid solution for acid etching; and (2) putting the implant after the acid etching as a matrix into a magnetron sputtering sample introduction chamber, putting anti-osteoporotic strontium salt used as a target material into a main sputtering chamber, vacuumizing the main sputtering chamber and the sample introduction chamber, pre-sputtering the matrix for 20 minutes in the sample introduction chamber, sending the implant matrix into the main sputtering chamber, sputtering for 2-4 hours, taking out the samples from the main sputtering chamber, and performing post-treatment in a heat treatment furnace, with a post-treatment temperature being 300-500 DEG C and an insulation time being 2-4 hours. The coating provided by the invention has characteristics of high adhesion strength with the matrix, osteoporosis resistance, micro / nano biomimetic structure.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

Small-size calcium phosphate fiber as well as preparation method and application thereof

ActiveCN113577103AEasy to operateRaw materials are easy to getInorganic phosphorous active ingredientsPharmaceutical delivery mechanismCalcium biphosphateFiber

The invention discloses a small-size calcium phosphate fiber, as well as a preparation method thereof and the application of the small-size calcium phosphate fiber in preparation of a medicine for repairing fracture. The preparation method comprises the following steps: completely dissolving polyvinyl alcohol in deionized water at 90-100 DEG C, and then cooling to normal temperature to obtain a solution A, the mass concentration of polyvinyl alcohol in the solution A being 0.5-1%; dispersing amorphous calcium phosphate of which the size is less than 3nm into absolute ethyl alcohol to obtain a mixed solution B, wherein the concentration of the calcium phosphate in the mixed solution B is 5-20mg / mL; dissolving arginine in deionized water at normal temperature to obtain a solution C, wherein the mass concentration of the arginine in the solution C is 0.5-3%; under stirring, dropwise adding the mixed solution B and the solution C into the solution A, uniformly mixing, performing ultrasonic treatment for 20-40 minutes after dropwise adding is completed, finally performing air drying at normal temperature to form a thin film, and screwing the thin film to obtain the small-size calcium phosphate fiber. The volume ratio of the mixed solution B to the solution C to the solution A is 1: 1: 1.

Owner:ZHEJIANG UNIV

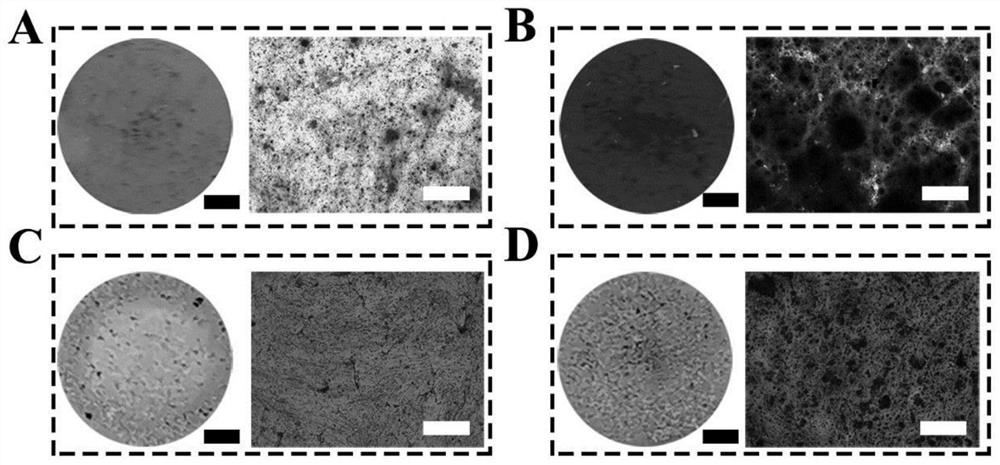

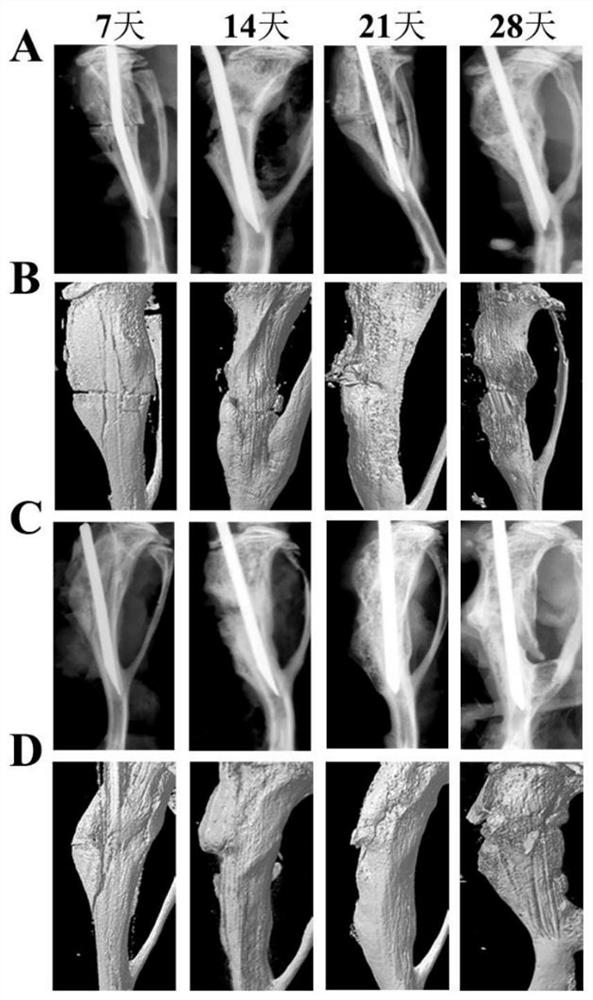

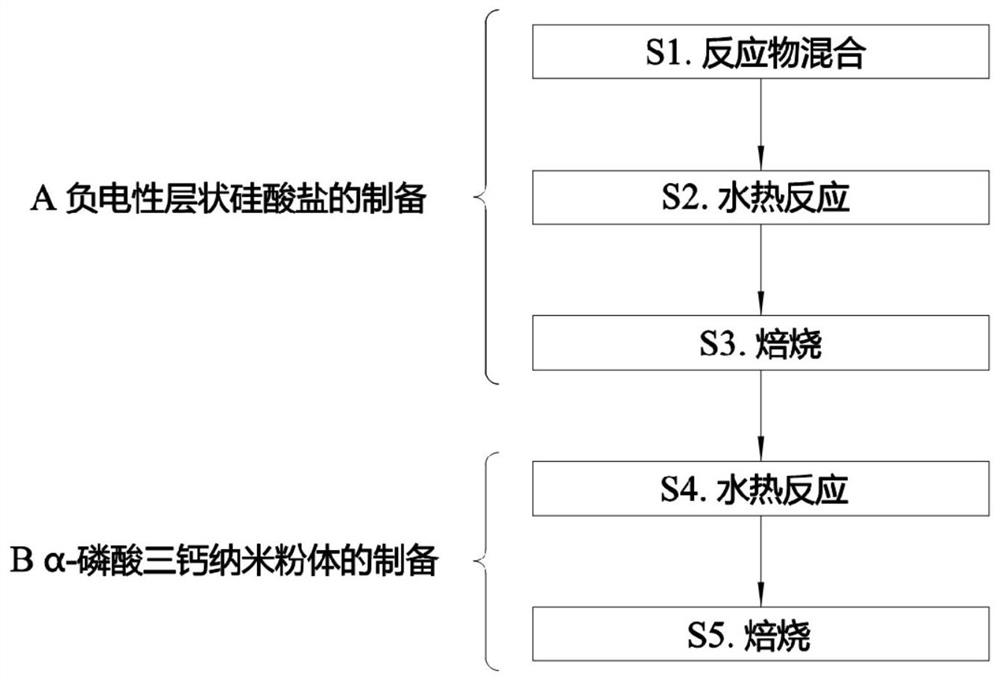

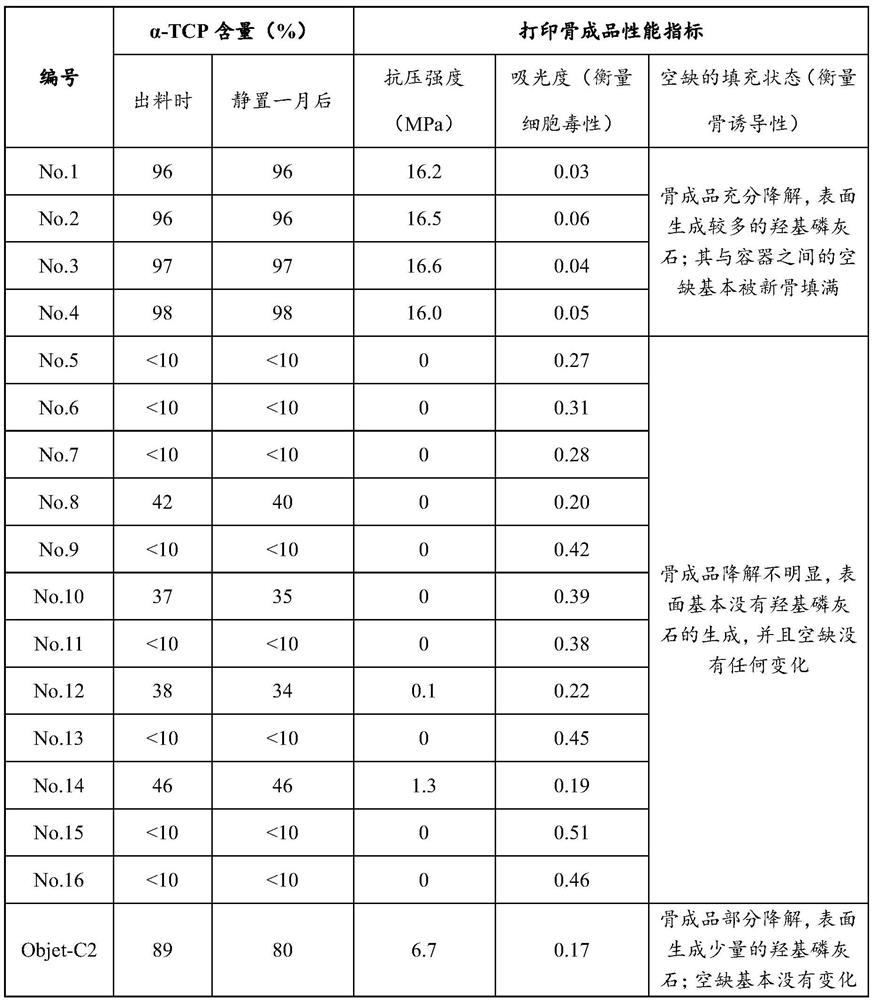

Preparation method of high-osteoinductivity alpha-tricalcium phosphate nano-powder for 3D printing

PendingCN114148995AExcellent osteoinductive propertiesBroad prospects for biomedical applicationsMaterial nanotechnologyAdditive manufacturing apparatusOsteoinductalPhosphoric acid

The preparation method of the high-osteoinductive alpha-tricalcium phosphate nano-powder for 3D printing comprises the following steps: S1, reactant mixing: firstly, mixing rare earth, lithium salt, calcium salt and a cosolvent in a solvent, and then slowly dropwise adding water glass; s2, hydrothermal reaction: carrying out reaction for 30 to 60 minutes at the temperature of 150 to 200 DEG C; s3, roasting: cooling the product, filtering and washing, and roasting the filter cake at 200-300 DEG C for 10-30 minutes to obtain electronegative layered silicate; s4, hydrothermal reaction: mixing reactants, heating to 100-150 DEG C, and reacting for 1-3 hours; s5, roasting: cooling a product, filtering, washing, and roasting a filter cake at 400-500 DEG C for 60-90 minutes; and S6, grinding: grinding a product to obtain the alpha-tricalcium phosphate nano powder. The problem of poor osteogenesis effect of the alpha-TCP / 3D printing bone finished product is creatively and thoroughly solved by introducing the electronegative layered lamellar crystals, the bone finished product is an ideal bone repair material, the bone induction performance of the bone finished product is excellent, and the bone induction performance of the bone finished product is far better than that of alpha-TCP similar products produced in the prior art or imported abroad, so that the bone finished product has very wide biomedical application prospects.

Owner:ZHONGSHAN POLYTECHNIC

Preparation method of bovine cortical bone grafting material

The invention discloses a method for preparing a bovine cortical bone grafting material, comprising the following steps: degreasing and decalcifying a cleaned bovine cortical bone block, immersing the bovine cortical bone block in an inhibitor of a bone morphogenetic protein degrading enzyme, then performing deproteinization, and finally obtaining the bovine cortical bone grafting material by freezing and drying. The preparation method has the advantages of simple steps, wide material source, low cost, low antigenicity of the obtained bone grafting material, strong bone formation inducibility, high biomechanical strength.

Owner:胡懿郃

A preparation method of nano-loaded zinc hydroxyapatite porous bioceramics

The invention discloses a preparation method of hydroxyapatite porous bioceramics loaded with nanometer zinc, belonging to the technical field of preparation of biomedical materials. The method of the present invention is to weigh nano-hydroxyapatite (99%-97%) and nano-zinc (1%-7%) powder according to the mass ratio, and then perform ball milling to obtain a composite powder, and mix the composite powder with a pore-forming agent The ammonium bicarbonate is mixed, and after being uniformly mixed, the green body is obtained by pressing, and the porous bioceramics of hydroxyapatite loaded with nanometer zinc is prepared by using the discharge plasma sintering technology. The porous bioceramic prepared by the present invention not only has uniform and pure composition, the porosity of the material is controllable between 40-70%, the compressive strength is 82-162Mpa, and the pore size is 50-600μm; and the addition of zinc can significantly improve the porosity. Osteogenic induction ability of bioceramics, the degradation rate matches the osteogenesis rate; it is suitable for bone scaffolding, filling and repairing materials.

Owner:KUNMING UNIV OF SCI & TECH

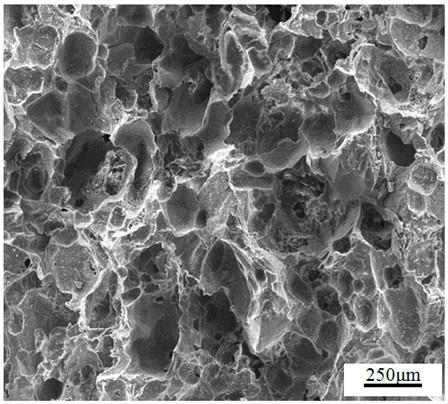

Hydroxyapatite ceramic/graphene composite bone tissue replacement material and its preparation

ActiveCN108478862BMeet the requirements for replacement materialsHigh mechanical strengthTissue regenerationProsthesisHydroxyapatite ceramicsBone tissue

The invention belongs to the field of bone tissue replacement materials, and relates to a porous hydroxyapatite ceramic / graphene composite bone tissue replacement material and a preparation method thereof. The invention provides a method for preparing a hydroxyapatite ceramic / graphene composite bone tissue replacement material, which sequentially comprises: preparing nano-hydroxyapatite / chitosan / graphene slurry, preparing porous hydroxyapatite / graphene Composite support and sintering molding; the method for preparing the composite support is: immerse the polyurethane sponge in the hydroxyapatite / chitosan / graphene slurry, and fill the pores in the polyurethane sponge with the slurry by extruding the polyurethane sponge, Just take it out and carry out vacuum drying; during the vacuum drying process, the vacuum temperature is 40-80°C, and the vacuum degree is 60-90KPa. The obtained bone tissue replacement material has a porous structure, has high mechanical strength and porosity, and can meet the requirements of the bone tissue replacement material.

Owner:SICHUAN UNIV

Novel collagen and bioactive ceramic composite bone grafting material and preparation method thereof

ActiveCN114588313AGood biocompatibilityPromote degradationTissue regenerationProsthesisPhospholipinCeramic composite

The invention discloses a novel collagen and bioactive ceramic composite bone grafting material and a preparation method thereof, and belongs to the field of biomedical materials.The composite bone grafting material comprises collagen, bioactive ceramic, chitosan quaternary ammonium salt and phosphatidylserine, according to the composite bone grafting material, phosphatidylserine-doped collagen and bioactive ceramic are used as scaffold materials, and chitosan quaternary ammonium salt is grafted on the surface of the scaffold materials. The composite bone grafting material disclosed by the invention can realize gradient regulation and control of sterilization, inflammatory response and osteoblast proliferation and differentiation, and can effectively inhibit operation infection, reduce inflammatory response, improve bone induction capability and realize efficient bone tissue repair.

Owner:BEIJING NATON INST OF MEDICAL TECH CO LTD

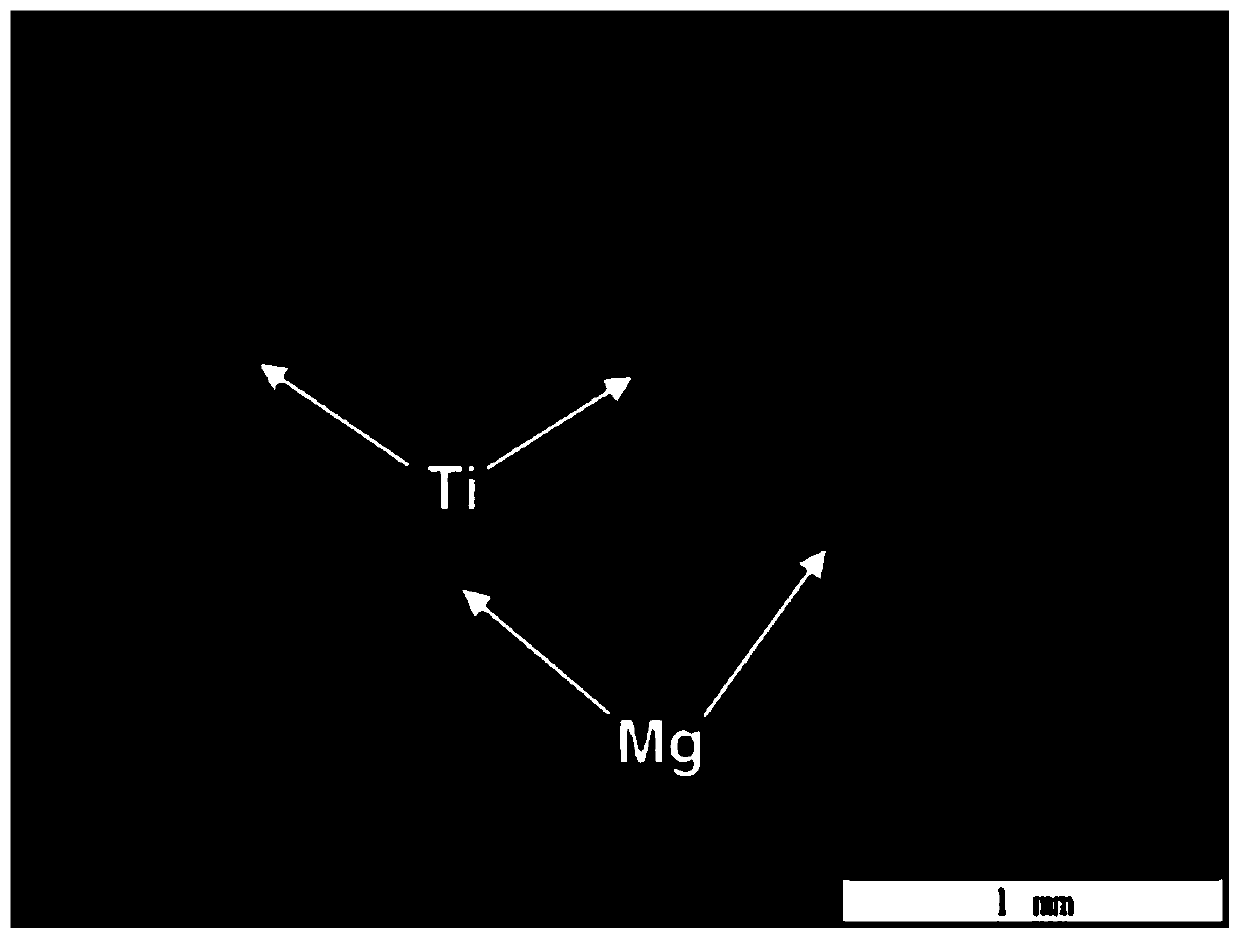

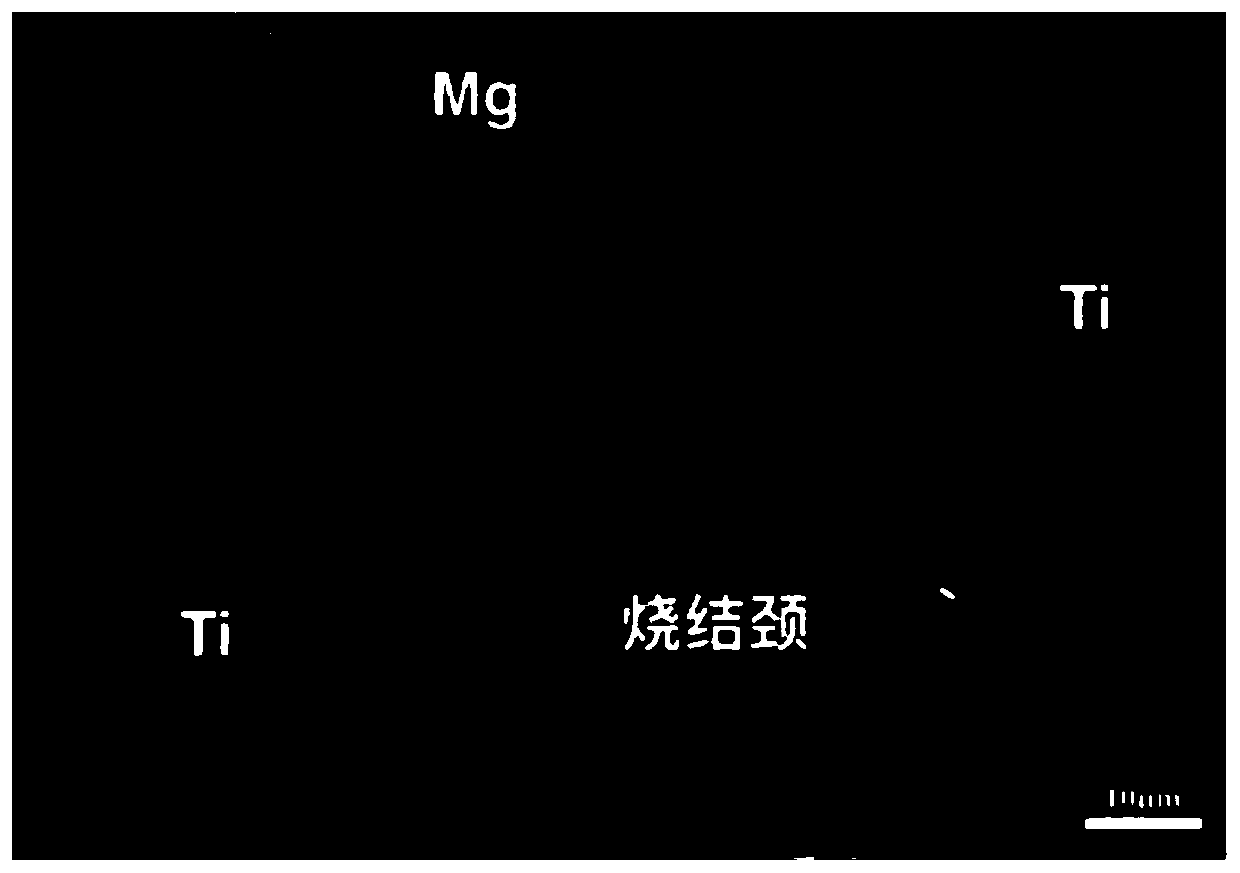

A kind of biconnected structure titanium-magnesium composite material and its preparation method and application

ActiveCN111266592BSolve the difficult problem of preparing titanium-magnesium composite materialsImprove mechanical propertiesTransportation and packagingMetal-working apparatusMetallic materialsBiocompatibility

The invention discloses a titanium-magnesium composite material with a double-connected structure and its preparation method and application, and relates to the technical field of biomedical metal material preparation. The preparation method includes the following steps: uniformly mixing titanium powder and magnesium powder by homogenizing ball milling to obtain titanium magnesium Composite material powder; drying the composite material powder and performing pre-pressing and shaping to obtain a titanium-magnesium composite material rough billet; performing high-temperature and high-pressure sintering on the composite material rough billet to obtain a double-connected structure titanium-magnesium composite material. The invention has a simple process and a short process, and adopts a high-temperature and high-pressure solid-phase sintering process, which solves the problems of microstructure regulation such as magnesium oxidation burning loss and uneven distribution, and the sintering problems of low material density and poor mechanical properties existing in the traditional powder metallurgy method. The double-connected titanium-magnesium composite material prepared by the invention is a novel biomedical composite material integrating excellent mechanical properties, biocompatibility, osteogenic inductivity and osteogenic integration, and has good application prospects.

Owner:YANSHAN UNIV

Bioactive ceramic armor with mechanical adaptability and preparation method thereof

ActiveCN111346260AGood osteoinductivityEvenly distributedTissue regenerationProsthesisSkull InjuriesSkeletal tissue

The invention provides a bioactive ceramic armor with mechanical adaptability and a preparation method thereof. Chitosan, polycaprolactone and hydroxyapatite are used as rigid ceramic units, polycaprolactone is used as a flexible joint part for connecting all the ceramic units, and a rigid and flexible bioactive ceramic armor material is constructed in an in-situ bionic mode through a casting molding technology. The bioactive armor material prepared by the preparation method disclosed by the invention not only has certain mechanical adaptability, but also has good biological activity. For infant skull injury repair and skull repair in complex dynamic mechanical environments such as intracranial high pressure, by implanting the ceramic armor, the mechanical extension requirement can be adaptively matched, meanwhile, the healthy growth of defective skull tissues is induced, and the normal form and function of the repaired tissues are realized.

Owner:SICHUAN UNIV

Bone matrix material containing various proteins secreted by umbilical cord mesenchymal stem cells and preparation method thereof

ActiveCN103480040BNon-immunogenicOsteoconductiveSkeletal/connective tissue cellsProsthesisBone tissueTissue engineered bone

The invention relates to a bone matrix material containing various proteins secreted by umbilical cord mesenchymal stem cells and a preparation method thereof. The material is an animal bone matrix material with the umbilical cord mesenchymal stem cells inoculated on the surface of a decalcified bone matrix and used for secreting osteogenic induction function proteins to promote osteogenesis. The bone matrix material has natural structures and characteristics of bone tissues and a good osteogenic induction effect, has a better osteogenesis promoting effect in a bone defect repair process, and is helpful for large-scale preparation and clinical application of tissue-engineered bones.

Owner:THE FIRST AFFILIATED HOSPITAL OF THIRD MILITARY MEDICAL UNIVERSITY OF PLA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com