A kind of biconnected structure titanium-magnesium composite material and its preparation method and application

A composite material and double-connection technology, applied in the field of biomedical metal materials, can solve the problems of difficult material structure regulation, complex sintering process, poor mechanical properties, etc., and achieve the effect of solving difficult tissue regulation, simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] A method for preparing a titanium-magnesium composite material with a double-connected structure, comprising the steps of:

[0041] (1) Homogenizing ball milling: Weigh titanium powder and magnesium powder of preset quality and put them into a ball mill tank, add an appropriate amount of viscous dispersant, mix titanium powder and magnesium powder evenly through ball milling, and obtain titanium-magnesium composite material powder Standby; the volume fraction of the magnesium powder is 40%-60%, and the average particle size is 100 μm; the average particle size of the titanium powder is 50-200 μm. The ball milling time is 0.5-2 hours, the rotational speed of the ball mill is 200-300 rpm, and the ball-to-material ratio is 0.5:1-2:1. The viscous dispersant is selected from isopropanol, glycerin or petrolatum and the like.

[0042] The titanium powder is selected from pure titanium powder or titanium alloy powders such as Ti-Nb and Ti-Mo that do not contain harmful alloy e...

Embodiment 1

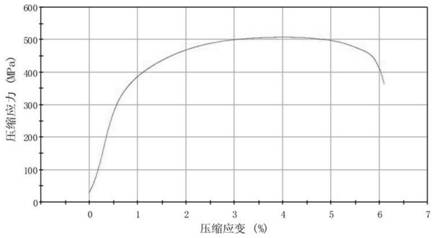

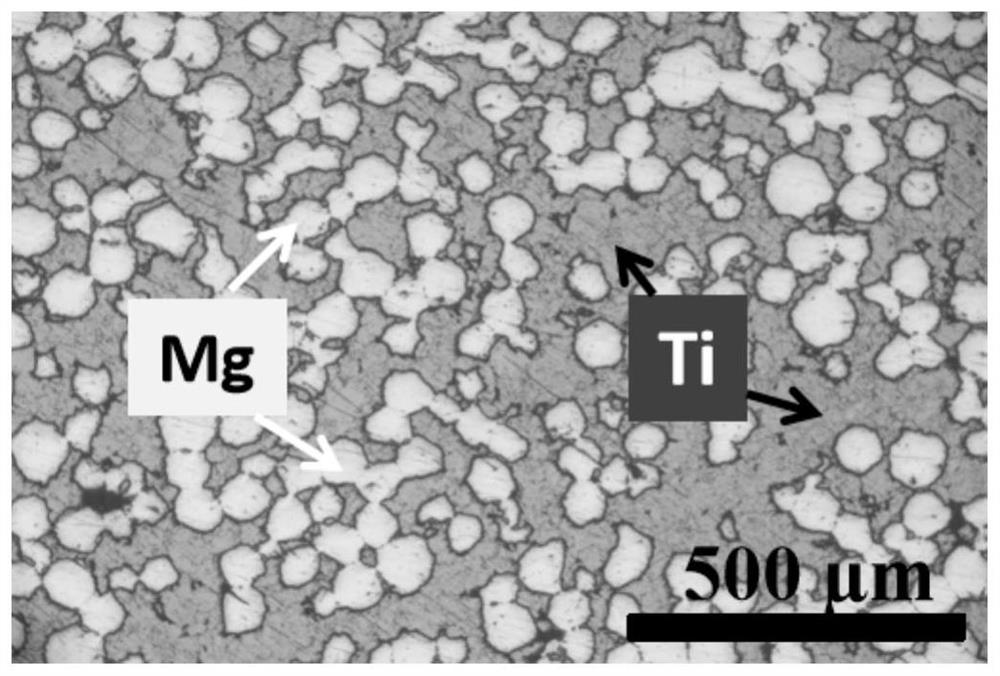

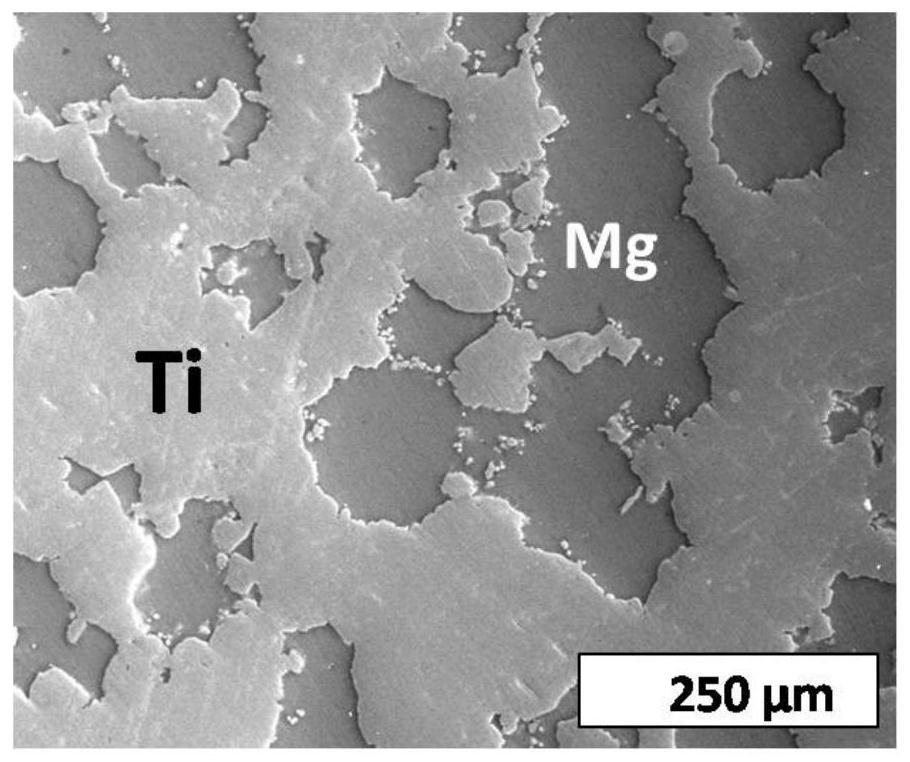

[0047] What this embodiment prepares is that the volume fraction of magnesium is 50% biconnected structure titanium-magnesium composite material, and preparation method is carried out according to the following steps:

[0048] Weigh titanium powder and magnesium powder according to the specified ratio, a total of 4g. The magnesium powder is 1.12g, the titanium powder is 2.88g; wherein the average particle size of the titanium powder is 100 μm, and the average particle size of the magnesium powder is 100 μm, and a titanium-magnesium composite raw material powder with a magnesium volume fraction of 50% is obtained. Put the powder into a ball mill jar, then add 1% isopropanol dispersant by mass fraction, and add 4g of agate grinding balls. The titanium powder and the magnesium powder are uniformly mixed by ball milling, the ball milling time is 1 h, and the rotational speed of the ball mill is 250 rpm. The ball-milled powder was dried at room temperature for 1 h. Then put the d...

Embodiment 2

[0054] What this embodiment prepares is that the volume fraction of magnesium is 40% biconnected structure titanium-magnesium composite material, and preparation method is carried out according to the following steps:

[0055] Weigh titanium powder and magnesium powder according to the specified ratio, a total of 8g. The magnesium powder is 0.82g, and the titanium powder is 3.18g; the average particle size of the titanium powder is 200 μm, and the average particle size of the magnesium powder is 100 μm. The powder is packed into a ball mill jar, then 1% mass fraction of isopropanol dispersant is added, and 16g of agate grinding balls are added. The titanium powder and the magnesium powder were uniformly mixed by ball milling, the ball milling time was 2 hours, and the rotational speed of the ball mill was 300 rpm. The ball-milled powder was dried at room temperature for 1 h. Then put the dry and united powder into a mold, and pre-press the powder under a pressure of 300 MPa ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com