Method for preparing strontium-containing biological composite material based bone bracket

A composite material and bone scaffold technology, applied in the field of 3D printing, can solve the problems of slow repair of bone defects and difficult to heal, and achieve the effects of good biocompatibility, suitable degradation rate, and good osteogenic induction ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The invention discloses a method for preparing a strontium-containing biocomposite material, which is formed by cross-linking a bioinorganic material and a strontium alginate composite slurry through a solution containing strontium ions, and the bioinorganic material is bioceramic and bioglass One or more; the solution containing strontium ions includes but not limited to strontium chloride solution, strontium nitrate solution, and the specific steps include:

[0032] Step 1: preparing sodium alginate solution;

[0033] Step 2: adding the bio-inorganic material powder into the sodium alginate solution several times and dispersing evenly to obtain the bio-inorganic material-sodium alginate suspension;

[0034] Step 3: Cross-link the bio-inorganic material-sodium alginate suspension obtained in step 2 with a solution containing strontium ions. The cross-linking time is more than 1 min, and the cross-linking temperature is controlled at 4-80°C to obtain a strontium-contain...

Embodiment 1

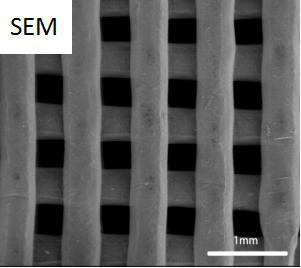

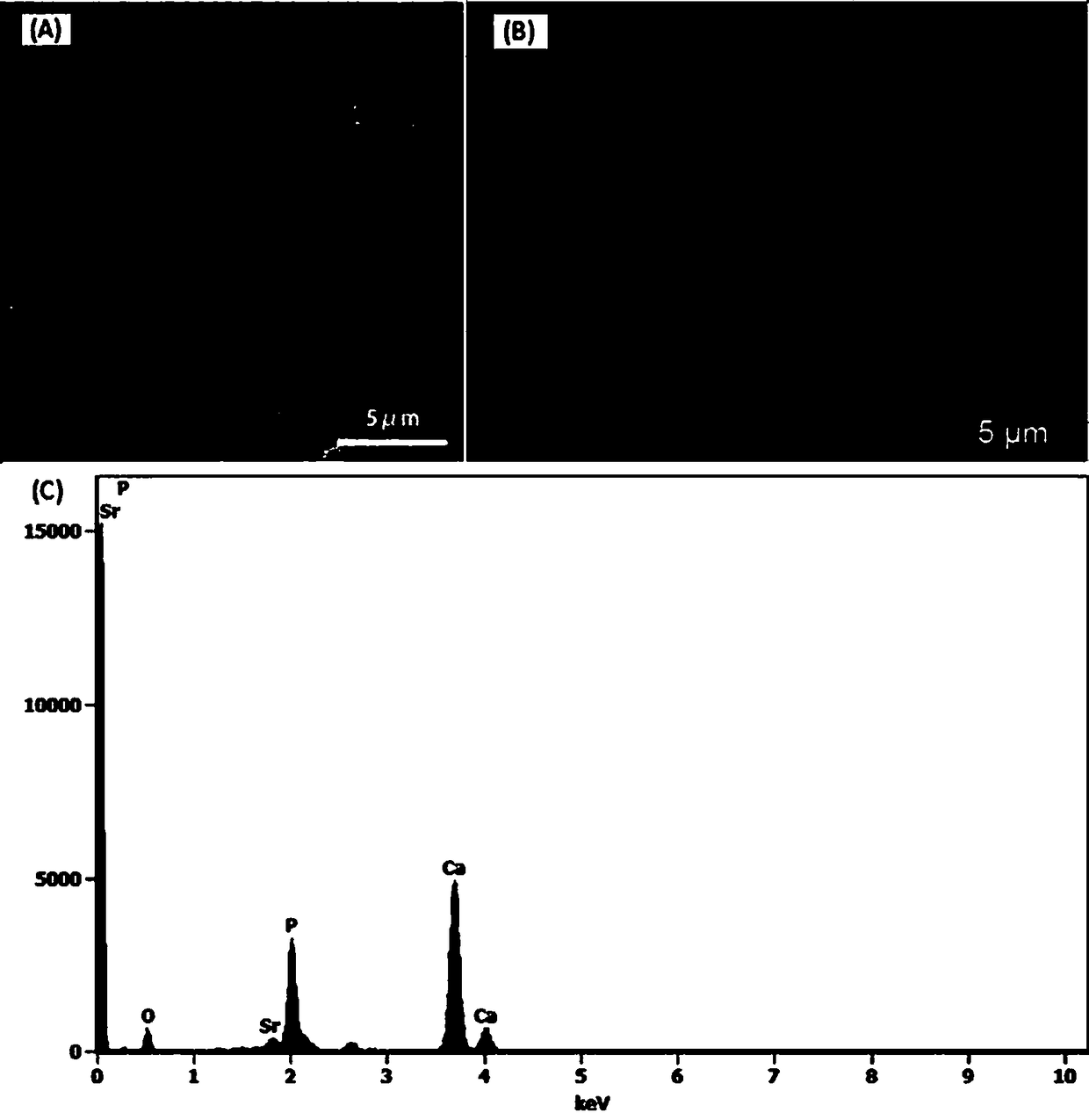

[0049]Weigh 1g of sodium alginate powder and 30g of distilled water, mix them with a magnetic stirrer for 1 hour to obtain a uniformly dispersed sodium alginate solution; then weigh 26g of nano-sized hydroxyapatite powder and add it to the sodium alginate solution Perform ball milling to obtain the hydroxyapatite-sodium alginate composite slurry; then add the hydroxyapatite-sodium alginate composite slurry to an extrusion deposition 3D printer to print a three-dimensional porous scaffold, and the printed scaffold is quickly placed in a 5wt Cross-link in %SrCl2 solution for 24 hours; the cross-linked scaffold is fully dried, and then placed in a muffle furnace for sintering, the heating rate and cooling rate are 5°C / min, 1200°C for 2 hours, and the strontium-containing scaffold is obtained after sintering. The porous hydroxyapatite scaffold (as attached figure 1 shown).

Embodiment 2

[0051] Weigh 0.5g of sodium alginate powder and 30g of distilled water, mix the two with a mechanical stirrer for 1 hour to obtain a uniformly dispersed sodium alginate solution; then weigh 20g of nano-scale calcium silicate powder and add it to the sodium alginate solution Perform ball milling to obtain calcium silicate-sodium alginate composite slurry; then freeze-dry the calcium silicate-sodium alginate composite slurry with liquid nitrogen cryogenic treatment, and place the freeze-dried porous scaffold in 10wt% SrCl2 solution Cross-link for 24 hours; the cross-linked scaffold is fully dried, and then placed in a microwave sintering furnace for sintering. The heating rate and cooling rate are 10°C / min, and the temperature is kept at 1000°C for 1 hour. After sintering, strontium-containing calcium silicate is obtained. Porous scaffold.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com