Active element doped mineralized collagen nanofiber and preparation method thereof

A technology of active elements and mineralized collagen, which is applied in the field of biomedical materials, can solve the problems of complex and cumbersome methods and limit the development and application of artificial synthetic materials, and achieve the effect of bone regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

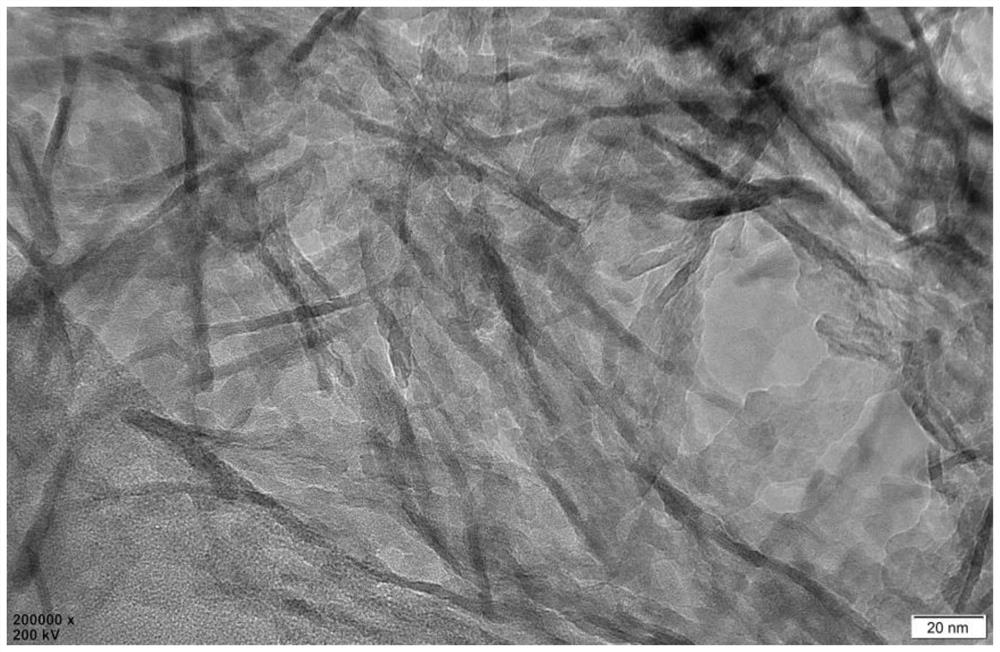

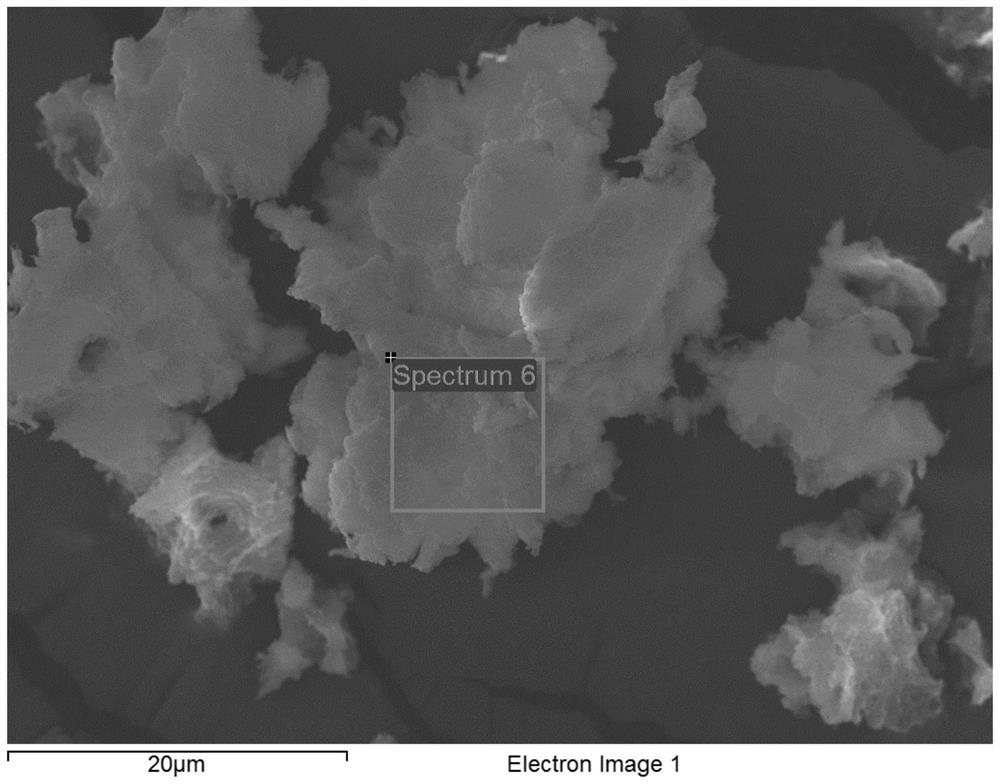

Image

Examples

Embodiment 1

[0056] (1) Dissolve the type I collagen sponge in ultrapure phosphoric acid aqueous solution, wherein the concentration of the phosphoric acid solution is 0.5mol / L, and the volume ratio of the mass of the type I collagen sponge to the phosphoric acid solution is 0.1g:1L. The obtained mixture was thoroughly mixed by stirring with a magnetic stirrer, and the mixing time was 6 hours, so that the added type I collagen template was fully dissolved, and recorded as an anion solution for future use. During the stirring process, the temperature of the system was maintained between 35-38°C.

[0057] (2) Prepare calcium chloride ultrapure aqueous solution, and add CaCl according to the preset doping cation salt (Sr) molar relative percentage of 9%. 2 Stir in the solution and dissolve evenly (that is, the molar ratio of strontium ions to calcium ions is 9:91).

[0058] Configure NaOH ultrapure aqueous solution to ensure that the molar ratio of (calcium ion + strontium ion) / OH is 2. Add...

Embodiment 2

[0069] (1) Dissolve the type I collagen sponge in ultrapure phosphoric acid aqueous solution, wherein the concentration of the phosphoric acid solution is 2mol / L, and the volume ratio of the quality of the type I collagen sponge to the phosphoric acid solution is 10g:1L. The obtained mixture was fully mixed by stirring with a magnetic stirrer, and the mixing time was 12 hours, so that the added type I collagen template was fully dissolved, and recorded as an anion solution for future use. During the stirring process, the temperature of the system was maintained between 35°C and 38°C.

[0070] (2) Prepare calcium chloride ultrapure aqueous solution, and add CaCl according to the preset doping cation salt (Sr) molar relative percentage of 7%. 2 Stir in the solution and dissolve evenly (that is, the molar ratio of strontium ions to calcium ions is 7:93).

[0071] Configure NaOH ultrapure aqueous solution to ensure that the molar ratio of (calcium ion + strontium ion) / OH is 2. A...

Embodiment 3

[0081] (1) Dissolve the type I collagen sponge in ultrapure phosphoric acid aqueous solution, wherein the concentration of the phosphoric acid solution is 1mol / L, and the volume ratio of the quality of the type I collagen sponge to the phosphoric acid solution is 2g:1L. The obtained mixture was thoroughly mixed by stirring with a magnetic stirrer, and the mixing time was 9 hours, so that the added type I collagen template was fully dissolved, and recorded as an anion solution for future use. During the stirring process, the temperature of the system was maintained between 35°C and 38°C.

[0082] (2) Prepare calcium chloride ultrapure aqueous solution, and add CaCl according to the preset doping cation salt (Sr) molar relative percentage of 7%. 2 Stir in the solution and dissolve evenly (that is, the molar ratio of strontium ions to calcium ions is 7:93).

[0083] Configure NaOH ultrapure aqueous solution to ensure that the molar ratio of (calcium ion + strontium ion) / OH is 2....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average length | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com