Dental implant of surface nano-structure and manufacturing method thereof

A technology of dental implants and nanostructures, applied in dental preparations, dental prostheses, dentistry, etc., can solve the problems of the interface between the coating and the substrate, the effect of the bonding strength is not obvious, and the coating is easy to dissolve, etc., to improve the long-term The clinical stability and success rate, the effect of improving the integration rate and good bone tissue compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

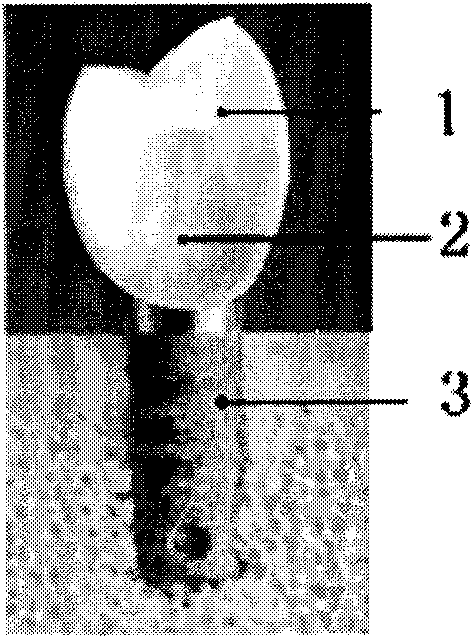

[0023] Such as figure 1 As shown, the dental implant 3 prepared in this embodiment is specifically arranged on the lower end of the abutment 2 , and the dental crown 1 is fixedly arranged on the upper end of the abutment 2 . The preparation of described dental implant 3 specifically comprises the following steps:

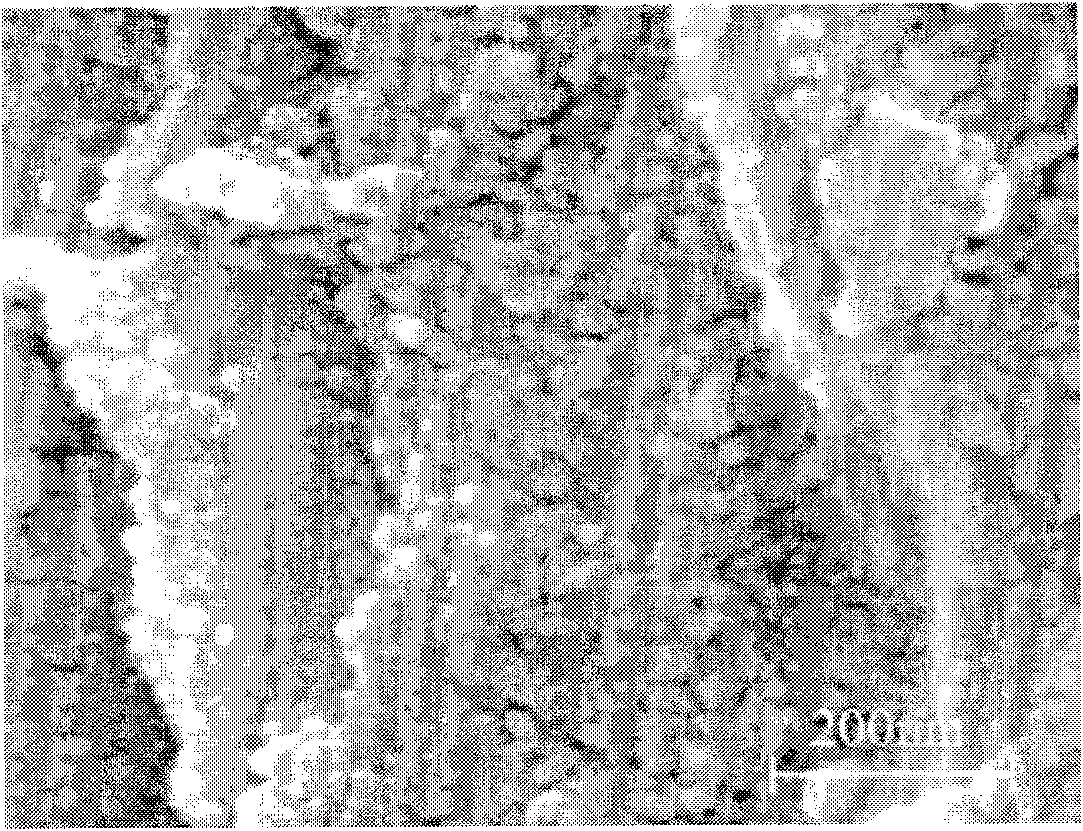

[0024] The cylindrical dental implant is treated with a surface nano treatment machine to make the implant form a surface nanostructure, such as figure 2 As shown, the surface grain size reaches about 10-50 nm.

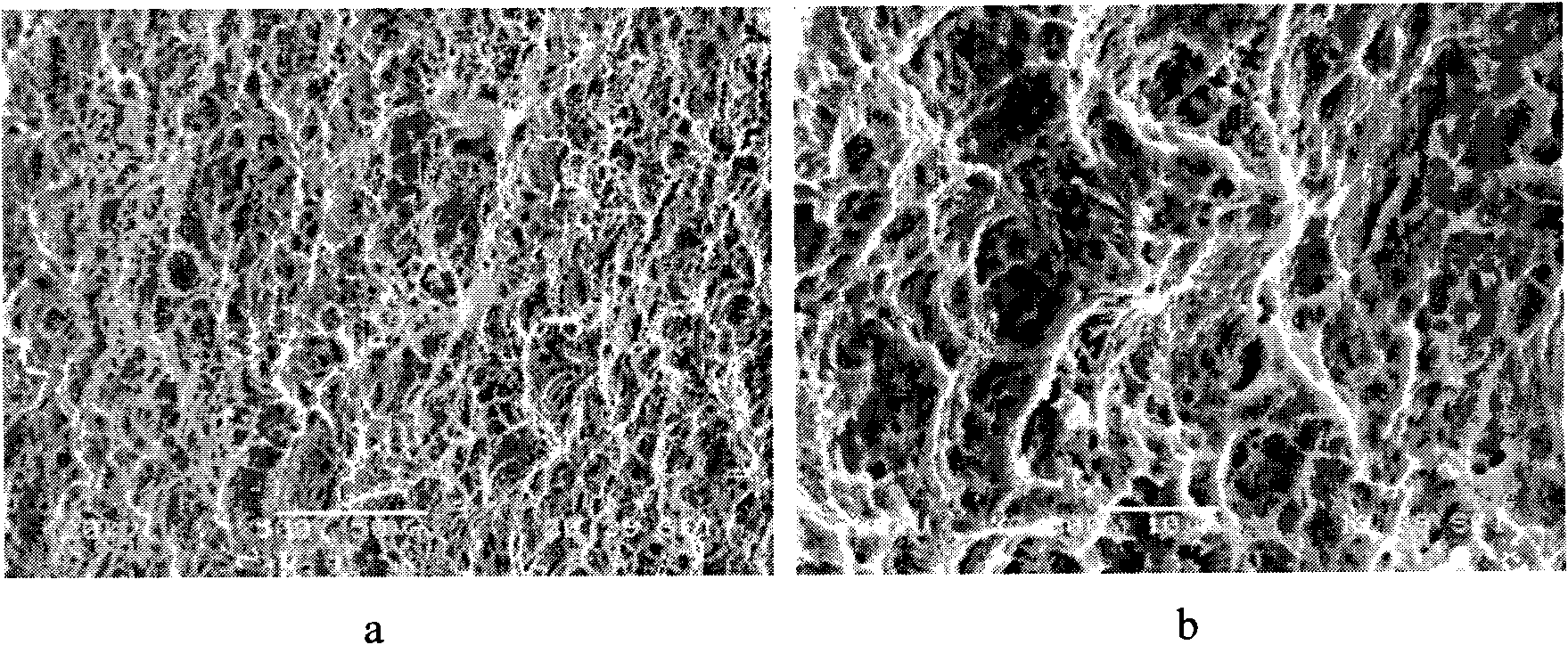

[0025] Then use 0.5mol / L hydrochloric acid to treat the nanometer surface, so that the surface nanostructure forms micron-scale holes, such as image 3 As shown in a and 3b, the diameter of the micron-sized holes is 100 nm-10 μm, and the micron-sized holes are evenly distributed on the surface of the dental implant.

Embodiment 2

[0027] A surface nano treatment machine is used to process the cylindrical dental implant, so that the implant forms a surface nano structure, and the surface grain size reaches about 50-100nm.

[0028] Then, 1mol / L hydrochloric acid is used to treat the nanometer surface to form micrometer-sized holes on the surface nanostructure. The diameter of the micrometer-sized holes is 100nm-10μm, and the micrometer-sized holes are evenly distributed on the surface of the dental implant.

Embodiment 3

[0030] The cylindrical dental implant is treated with a surface nano treatment machine, so that the implant forms a surface nanostructure, and the surface grain size reaches about 100-500nm.

[0031] Then, 1mol / L hydrochloric acid is used to treat the nanometer surface to form micrometer-sized holes on the surface nanostructure. The diameter of the micrometer-sized holes is 100nm-10μm, and the micrometer-sized holes are evenly distributed on the surface of the dental implant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com