Preparation method for titanium-magnesium double-metal composite of double-communication netted structure

A network structure and composite material technology, which is applied in the field of preparation of dual-connected network structure titanium-magnesium bimetallic composite materials, can solve the problems of poor biological activity, stress shielding, high elastic modulus, etc., and achieve low elastic modulus, Solve the effect of stress shielding and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

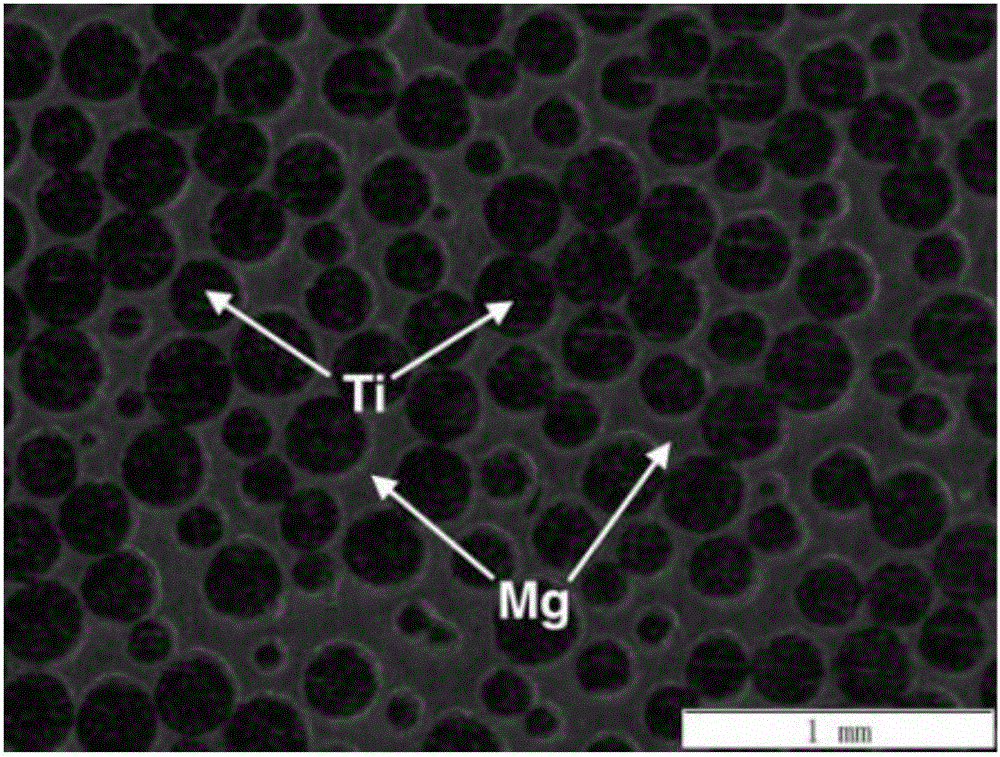

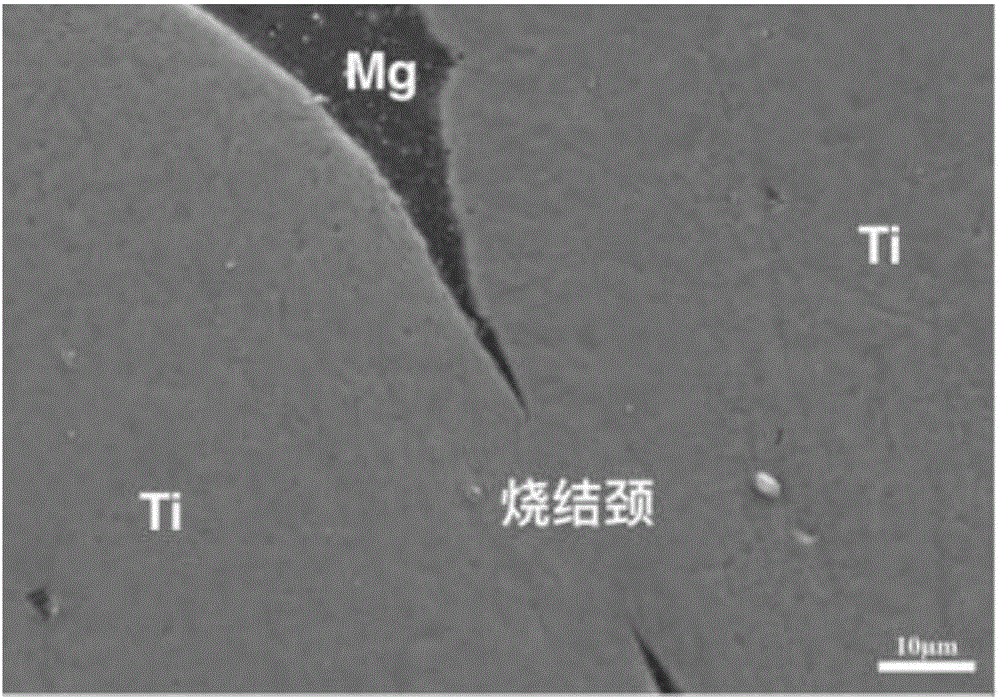

[0015] Specific embodiment one: the preparation method of a kind of biconnected network structure titanium-magnesium bimetallic composite material of this embodiment is carried out according to the following steps:

[0016] 1. Pre-sintering of cold-pressed loose-packed titanium powder at medium temperature: put the titanium powder into the mold, apply a pressure of 8MPa to 12MPa to compact the titanium powder, and then put the compacted titanium powder together with the mold into a vacuumized airtight container Carrying out vacuum sintering, raising the sintering temperature from room temperature to 800°C to 1000°C, keeping the temperature at 800°C to 1000°C for 0.5h to 1.5h, and cooling to room temperature to obtain a porous titanium pre-sintered body;

[0017] 2. Rough machining of porous titanium pre-sintered body: the porous titanium pre-sintered body is rough-machined into the shape and size required by the device blank by means of mechanical processing, and the volume shr...

specific Embodiment approach 2

[0024] Embodiment 2: This embodiment is different from Embodiment 1 in that: the titanium powder in step 1 is pure titanium, Ti-Nb alloy or Ti-Mo alloy. Other steps and parameters are the same as those in the first embodiment.

[0025] In this embodiment, titanium powders with different particle sizes and shapes can be selected, and porous titanium with different pore characteristics can be obtained, so that its mechanical properties can be adjusted according to different service requirements. The titanium powder composition can be selected from pure titanium powder and titanium alloy powder that does not contain harmful alloy elements such as Ti-Nb and Ti-Mo alloy powder.

specific Embodiment approach 3

[0026] Embodiment 3: This embodiment is different from Embodiment 1 or Embodiment 2 in that: the particle size of the titanium powder in step 1 is 180 μm-220 μm. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com