Preparation method of a porous hydroxyapatite/strontium oxide composite bone repair material

A technology of hydroxyapatite and strontium oxide, which is applied in ceramic products, manufacturing tools, prostheses, etc., can solve the problem that porous HA bone repair materials cannot fully meet the requirements of clinical use, the degradation rate does not match the crawling replacement rate of bone tissue, Reduce the problems of material biocompatibility and osteogenic activity, achieve good osteogenic induction ability, improve osteogenesis induction ability, and controllable pore parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In this example, the process steps of preparing porous HA / SrO composite bone repair material by spark plasma sintering are:

[0037] (1) According to the mass percentage of 99% hydroxyapatite and 1% strontium oxide, weigh hydroxyapatite with a purity of ≥99.7% and an average particle size of 100nm and strontium oxide powder with a purity of ≥99.7% and an average particle size of 5μm ;

[0038] (2) Put the hydroxyapatite powder and strontium oxide powder weighed in step (1) into the agate ball milling tank of the ball mill, add agate balls at a ball-to-material ratio of 3:1, then add absolute ethanol, and then ball mill and mix powder for 3 hours, and grind the slurry after ball milling to obtain mixed powder A;

[0039] (3) 70% of the mixed powder A and 30% of the mass percentage of ammonium bicarbonate obtained in step (2), respectively weigh the mixed powder A and the ammonium bicarbonate powder whose purity is analytically pure and has an average particle size of 300 ...

Embodiment 2

[0046] In this example, the process steps of preparing porous HA / SrO composite bone repair material by spark plasma sintering are:

[0047] (1) According to the mass percentage of 90% hydroxyapatite and 10% strontium oxide, respectively weigh hydroxyapatite with a purity of 99.7% and an average particle size of 100nm and strontium oxide powder with a purity of ≥99.7% and an average particle size of 10μm ;

[0048] (2) Put the hydroxyapatite powder and strontium oxide powder weighed in step (1) into the agate ball milling tank of the ball mill, add agate balls at a ball-to-material ratio of 3:1, then add absolute ethanol, and then ball mill and mix powder for 3 hours, and grind the slurry after ball milling to obtain mixed powder A;

[0049] (3) According to the mass percentage of mixed powder A 50% and ammonium bicarbonate 50% obtained in step (2), weigh mixed powder A and ammonium bicarbonate powder whose purity is analytically pure and whose average particle size is 400 μm;...

Embodiment 3

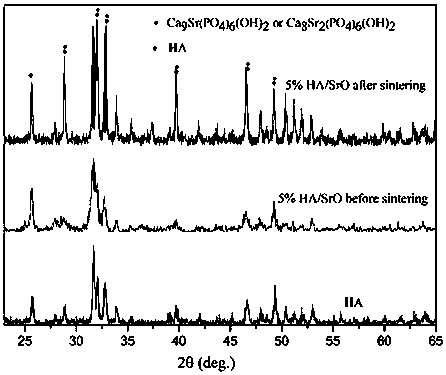

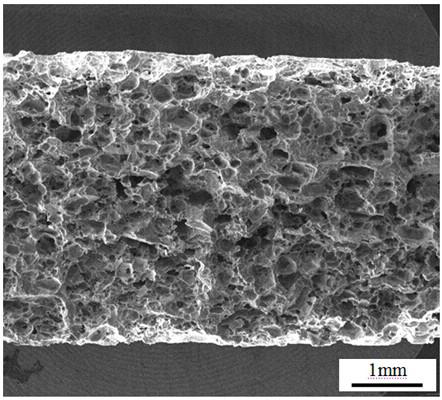

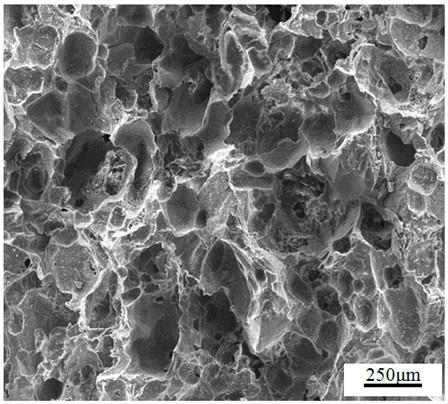

[0055] In this example, the process steps of preparing porous HA / SrO composite bone repair material by spark plasma sintering are:

[0056] (1) According to the mass percentage of 95% hydroxyapatite and 5% strontium oxide, weigh hydroxyapatite with a purity of ≥99.7% and an average particle size of 80nm and strontium oxide powder with a purity of ≥99.7% and an average particle size of 15μm ;

[0057] (2) Put the hydroxyapatite powder and strontium oxide powder weighed in step (1) into the agate ball milling tank of the ball mill, add agate balls at a ball-to-material ratio of 3:1, then add absolute ethanol, and then ball mill and mix Powder 5h, grind the slurry after ball milling after drying to obtain mixed powder A;

[0058] (3) According to the mass percentage of mixed powder A 40% and ammonium bicarbonate 60% obtained in step (2), weigh mixed powder A and ammonium bicarbonate powder whose purity is analytically pure and whose average particle size is 500 μm;

[0059] (4)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com