Small-size calcium phosphate fiber as well as preparation method and application thereof

A calcium phosphate, small size technology, applied in the field of biomedicine, can solve the problems of large size, unable to repair fractures, increase financial revenue and expenditure, etc., and achieve the effects of easy repeatability and industrial application, good degradability, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Polyvinyl alcohol is completely dissolved in deionized water at 95° C., and then cooled to normal temperature to obtain solution A. The mass concentration of polyvinyl alcohol in the solution A is 0.5%;

[0043] (2) Dispersing amorphous calcium phosphate with a size of about 1.5 nm in absolute ethanol to obtain a mixed solution B, the concentration of calcium phosphate in the mixed solution B is 10 mg / mL;

[0044] (3) dissolving arginine in deionized water at room temperature to obtain a solution C, the mass concentration of arginine in the solution C being 0.5%;

[0045](4) Under stirring, add mixed solution B and solution C to solution A drop by drop and mix evenly. After the dropwise addition, sonicate for 30 minutes. The thin film is twisted to obtain small-sized calcium phosphate fibers; the volume ratio of the mixed solution B, solution C, and solution A is 1:1:1.

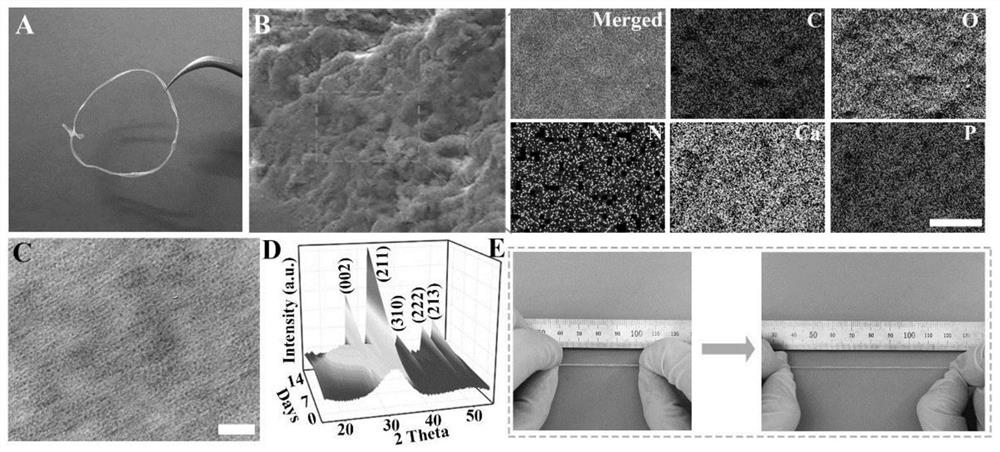

[0046] Such as figure 1 As shown in A, the obtained small-sized calcium phosphate fibers are ...

Embodiment 2

[0067] The difference from Example 1 is only that the mass concentration of polyvinyl alcohol in solution A is 1%, and all the other steps and conditions are the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com