Production method of high-temperature-resistant workable polyimide plastic alloy

A polyimide and plastic alloy technology, applied in the production field of polyimide plastic alloy, can solve the problems of high molding temperature, high price, low molding yield, etc., and achieve good high temperature resistance, low cost, high heat The effect of high deformation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Introduce nitrogen into a 300-liter stirred reactor, add 104.4kg dimethylacetamide, add 6kg 4.4'-diphenyl ether diamine under stirring, dissolve it at room temperature, and then add pyromellitic acid di Anhydride 6.66kg, the reaction temperature is controlled to be lower than 30°C, the viscosity of the reaction system increases gradually, and the viscosity is measured by sampling.

[0025] When the intrinsic viscosity of the resin reaches above 1.5, it can be diluted with a polar solvent, add 50kg of dimethylacetamide, stir evenly, add 26.88kg of polyethersulfone to dissolve it, dissolve it completely and stir evenly, and make the viscous The slurry was precipitated in coagulant ethanol, filtered, washed, and the filter cake was dried. The dried filter cake was pulverized into a powder, heat-treated at 300° C. for 3 hours, and cooled to obtain 38 kg of powder.

[0026] The powder was subjected to compression molding: the molding temperature was 360°C, the pressure was 1...

Embodiment 2

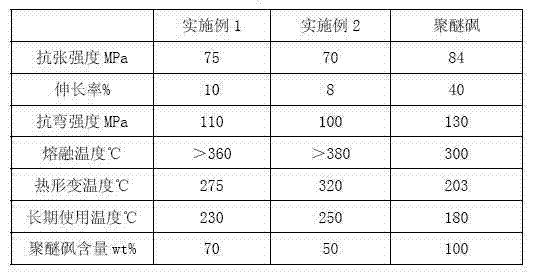

[0028] This example is operated in the same manner as Example 1, except that the amount of polyethersulfone resin added is changed to 11.52kg, and a total of 23kg of powder is obtained as the final product. The powder was subjected to compression molding: the molding temperature was 380°C, the pressure was 100MPa, the heat preservation and pressure were maintained for 60 minutes, cooled, and the plate was taken out. The measured properties are shown in Table 1.

[0029] Table 1

[0030]

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com