Light-sensitive coating and preparation process thereof

A technology of coatings and parts by weight, applied in the field of coatings, can solve problems such as difficulty in satisfying the individuality of different groups of people, cracked wall paint, single color, etc., and achieve the effects of increasing diversity, reducing severe cracking, and improving integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Embodiment 1: A kind of photosensitive coating, the component that comprises and its corresponding parts by weight are shown in Table 1, and adopt following steps to prepare and obtain:

[0055] S1, weigh 15 parts of deionized water, slowly add the corresponding parts by weight of polyacrylic acid sodium salt, fatty alcohol polyoxyethylene ethers, 0.35 parts of non-ionic modified silicone defoamer at a stirring speed of 400-800rpm, Mix for 3-10min to form the first mixture;

[0056] S2, slowly add rutile titanium dioxide R-996, calcined kaolin Ultrex96, and heavy calcium carbonate to the first mixture obtained in S1, gradually increase the stirring speed in the range of 800-1250rpm, and mix for 20-25min to form a second mixture;

[0057] S3, slowly add the remaining deionized water and hydroxyethyl cellulose colloid to the second mixture obtained in S2, the stirring speed is 1000-1250rpm, and mix for 10-15min to obtain the third mixture;

[0058] S4, adjust and maintai...

Embodiment 2-5

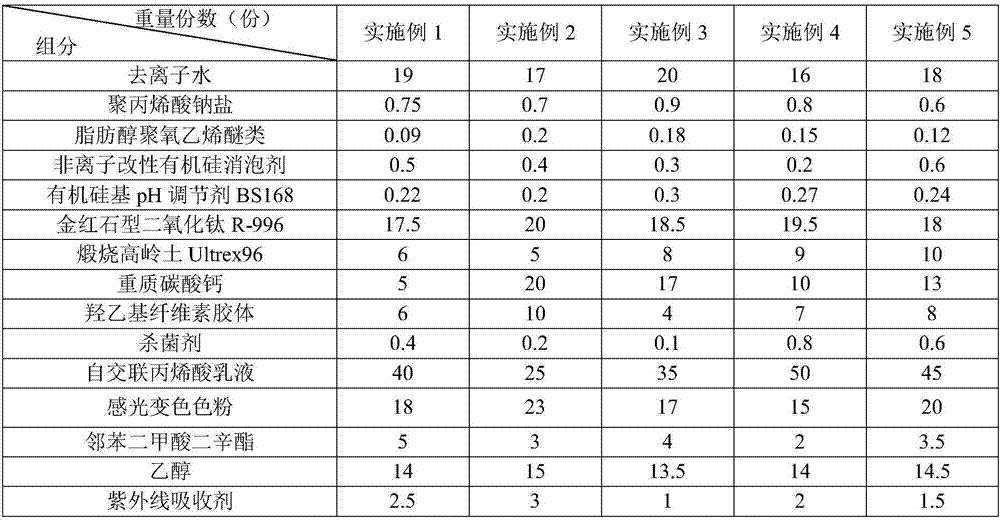

[0063] Embodiment 2-5: A photosensitive coating, the difference from Embodiment 1 is that the components and their corresponding parts by weight are shown in Table 1.

[0064] Components and their corresponding parts by weight in Table 1 Embodiment 1-5

[0065]

Embodiment 6

[0066] Embodiment 6: a kind of photosensitive coating, and the difference of embodiment 1 is that the ultraviolet absorber selects phenyl o-hydroxybenzoate, 2-hydroxyl-4-n-octyloxybenzophenone, the weight and number ratio of the two It is 1.1:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com