Ethylene propylene diene monomer grafted maleic anhydride and preparation method thereof

A technique for grafting EPDM rubber and maleic anhydride is applied in the field of grafting maleic anhydride on EPDM rubber and the preparation thereof, and can solve the problems of long grafting reaction time, limited application of EPDM and high production cost, Achieve the effects of high grafting rate and grafting efficiency, improving grafting rate and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

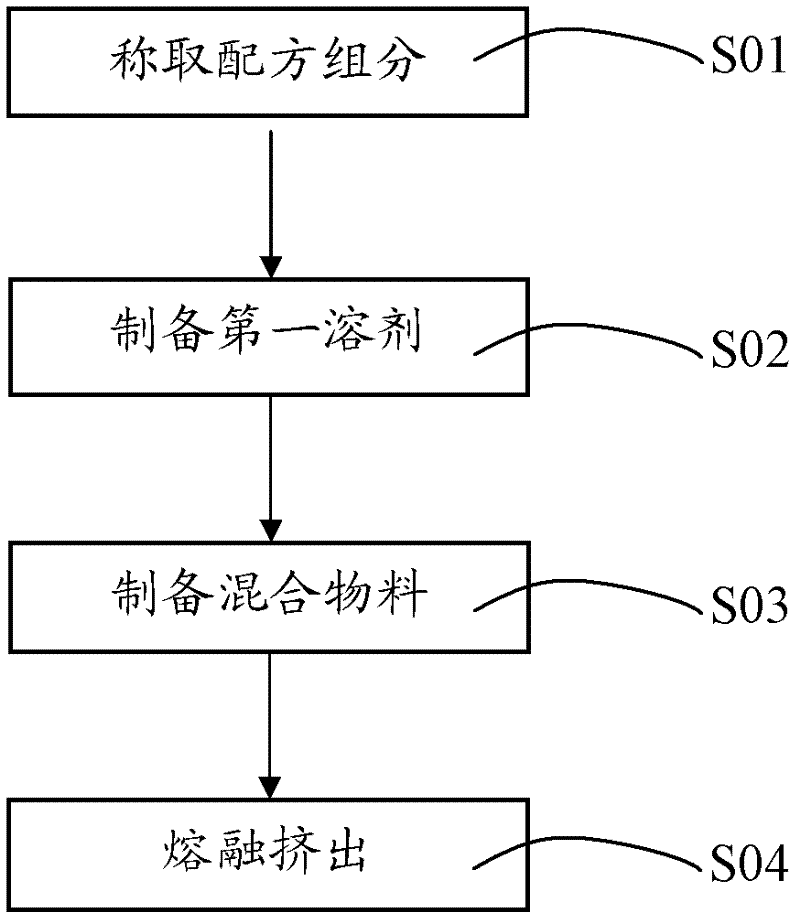

[0032] The embodiment of the present invention also provides the preparation method of above-mentioned EPDM grafted maleic anhydride, its technological process is as follows figure 1 shown. The method comprises the steps of:

[0033] S01. Weigh the formula components: weigh each component respectively according to the above-mentioned EPDM grafted maleic anhydride;

[0034] S02. Prepare the first solvent: dissolve the EPDM rubber weighed in step S01 in styrene monomer;

[0035] S03. Prepare the mixed material: add the initiator, maleic anhydride, and hexamethyl triamine phosphate weighed in step S01 to the first solution prepared in step S02 to obtain the mixed material;

[0036] S04. Melt extrusion: melt-extrude the mixed material in step S03, and granulate to obtain the EPDM grafted maleic anhydride.

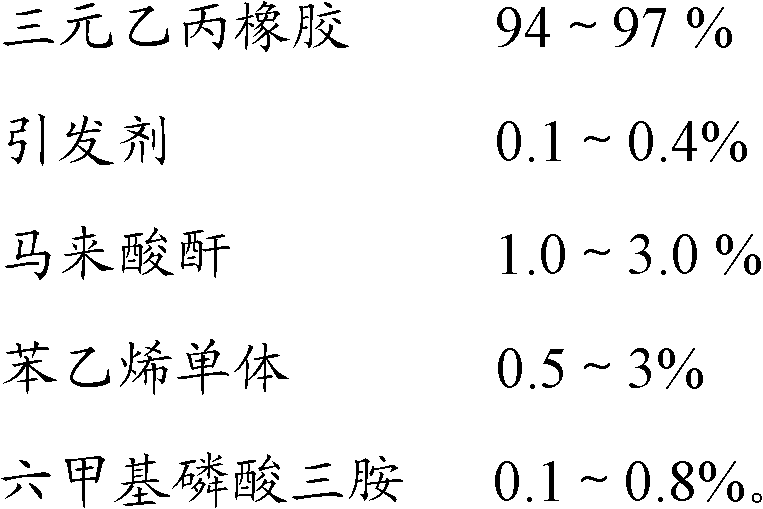

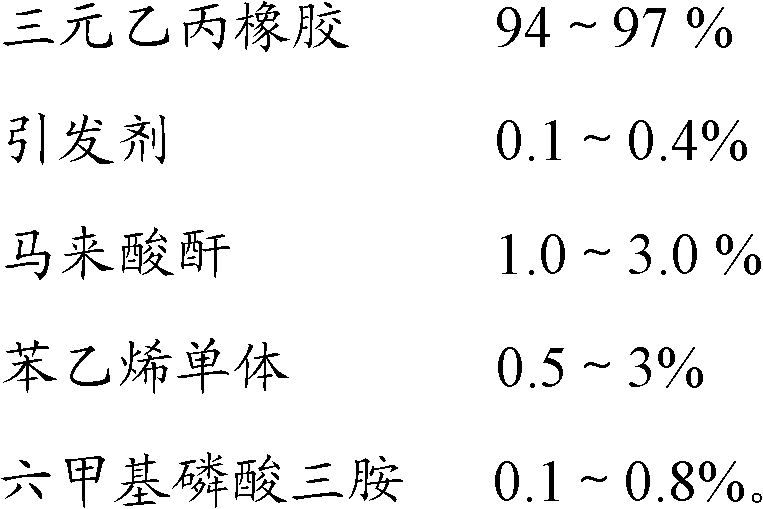

[0037] Specifically, in the above step S01, the formulation of EPDM rubber grafted with maleic anhydride and the preferred content and type of each component in the formulat...

Embodiment 1

[0046] A kind of EPDM rubber grafted with maleic anhydride, its weight percent formulation components are shown in the following Table 1.

[0047] Its preparation method is as follows:

[0048] Weigh the styrene monomer at 1% by weight and pour it into the container. Dissolve 0.15% of BIPB in the styrene monomer and stir evenly. %, 1010 / 1680.2 / 0.1%, and 0.7% of other processing aids were weighed, poured into a blender, slowly added the styrene / BIPB mixed solution prepared earlier to the material, and stirred evenly. The mixed material is put into the hopper of the twin-screw extruder, grafted through melting reaction, extruded and granulated. Among them, the temperature settings of each heating zone of the screw are: zone 1 temperature: 140°C; zone 2: 150°C; zone 3: 160°C; zone 4: 150°C; machine head: 160°C; ~6min, the pressure is 15MPa.

Embodiment 2

[0050] A kind of EPDM rubber grafted with maleic anhydride, its weight percent formulation components are shown in the following Table 1.

[0051] Its preparation method is as follows:

[0052] Weigh the styrene monomer at 1% by weight and pour it into the container. Dissolve 0.15% of BIPB in the styrene monomer and stir evenly. %, 1010 / 1680.2 / 0.1%, and 0.7% of other processing aids were weighed, poured into a blender, slowly added the styrene / BIPB mixed solution prepared earlier to the material, and stirred evenly. The mixed material is put into the hopper of the twin-screw extruder, grafted through melting reaction, extruded and granulated. Among them, the temperature settings of each heating zone of the screw are: zone 1 temperature: 140°C; zone 2: 150°C; zone 3: 160°C; zone 4: 150°C; machine head: 160°C; ~6min, the pressure is 15MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| grafting efficiency | aaaaa | aaaaa |

| grafting efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com