Heat-resistant, low-smoke and flame-retardant non-cross-linked cable material

A low-smoke, flame-retardant, non-crosslinking technology, which is applied in the field of polyolefin compositions, can solve problems such as insufficient heat resistance, and achieve the effects of improving flexibility, inhibiting crosslinking, and enhancing heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

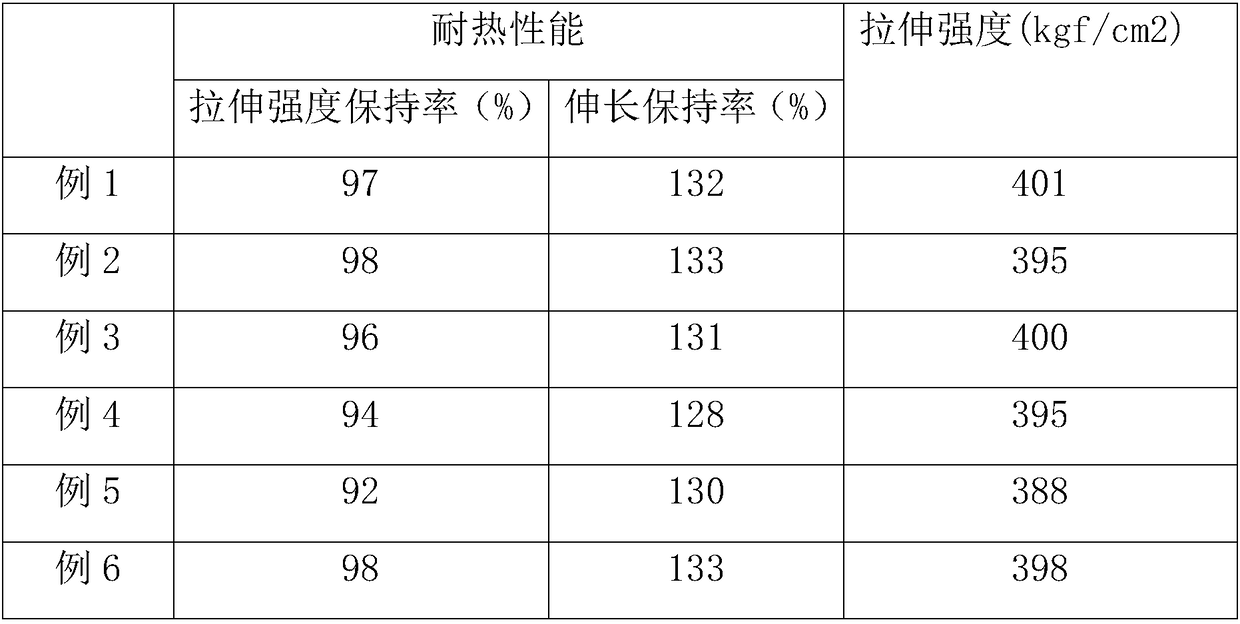

Examples

Embodiment 1

[0021] The heat-resistant, low-smoke and flame-retardant non-crosslinked cable material of this embodiment includes the following components by weight:

[0022] 30 parts of ethylene-vinyl acetate copolymer, 4 parts of styrene, 4 parts of 3-(2-furyl)acrylic acid, 4 parts of ethyl cinnamate, 10 parts of talcum powder, 1 part of magnesium-aluminum composite flame retardant, V- 1 part of Si4042 silicone, 10 parts of linear low density polyethylene, 10 parts of maleic anhydride, 5 parts of octene, 1 part of N, N-dimethylformamide, 1 part of dimethyl sulfoxide, 1 part of triphenyl phosphate 1 part of dimethyl acetal, 2 parts of cinnamoyl chloride, 1 part of diethylamine, 1 part of triethylamine, 2 parts of ultrafine zinc borate, 2,3-dimethyl-2,3-diphenyl 0.5 parts of butane, 0.5 parts of dibenzoyl peroxide; first, cinnamoyl chloride, diethylamine and triethylamine are added to petroleum ether dehydrated by 0.4nm molecular sieves, and the temperature is 35 ° C. pressure distillation...

Embodiment 2

[0024] The heat-resistant, low-smoke and flame-retardant non-crosslinked cable material of this embodiment includes the following components by weight:

[0025] 40 parts of ethylene-vinyl acetate copolymer, 8 parts of styrene, 8 parts of 3-(2-furyl)acrylic acid, 8 parts of ethyl cinnamate, 20 parts of talcum powder, 3 parts of magnesium-aluminum composite flame retardant, V- 3 parts of Si4042 silicone, 20 parts of linear low density polyethylene, 20 parts of maleic anhydride, 10 parts of octene, 4 parts of N, N-dimethylformamide, 4 parts of dimethyl sulfoxide, 4 parts of triphenyl phosphate 4 parts of dimethyl acetal, 4 parts of cinnamoyl chloride, 3 parts of diethylamine, 3 parts of triethylamine, 6 parts of ultrafine zinc borate, 2,3-dimethyl-2,3-diphenyl 2 parts of butane, 2 parts of dibenzoyl peroxide; first, cinnamoyl chloride, diethylamine and triethylamine are added to petroleum ether dehydrated by 0.4nm molecular sieve, and the reaction is stirred at 50°C for 24 hours ...

Embodiment 3

[0027] The heat-resistant, low-smoke and flame-retardant non-crosslinked cable material of this embodiment includes the following components by weight:

[0028] 30 parts of ethylene-vinyl acetate copolymer, 4 parts of styrene, 8 parts of 3-(2-furyl)acrylic acid, 4 parts of ethyl cinnamate, 20 parts of talcum powder, 1 part of magnesium-aluminum composite flame retardant, V- 3 parts of Si4042 silicone, 20 parts of linear low density polyethylene, 10 parts of maleic anhydride, 10 parts of octene, 1 part of N, N-dimethylformamide, 4 parts of dimethyl sulfoxide, 1 part of triphenyl phosphate 4 parts of dimethyl acetal, 2 parts of cinnamoyl chloride, 3 parts of diethylamine, 1 part of triethylamine, 6 parts of superfine zinc borate, 2,3-dimethyl-2,3-diphenyl 0.5 parts of butane, 2 parts of dibenzoyl peroxide; first, cinnamoyl chloride, diethylamine and triethylamine are added to petroleum ether dehydrated by 0.4nm molecular sieve, and the reaction is stirred at 35°C for 24 hours an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com