Preparation method and application of high temperature and high salinity stabilizer for drilling fluid

A high-temperature, high-salt, drilling fluid technology, applied in the direction of sulfonate preparation, drilling compositions, chemical instruments and methods, etc., can solve the problems of difficult product quality control and high production control requirements, and achieve easy product quality control, Improved hydrophilicity and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

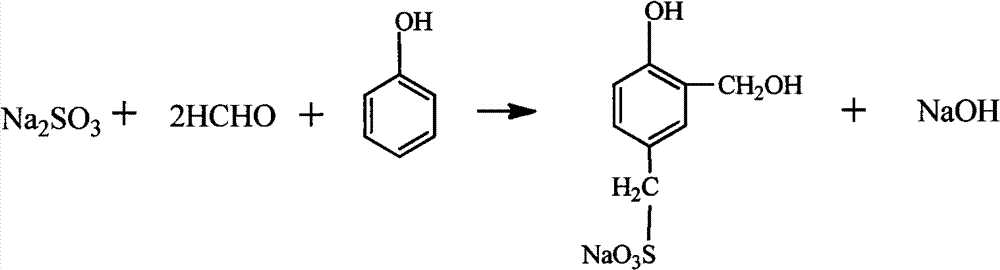

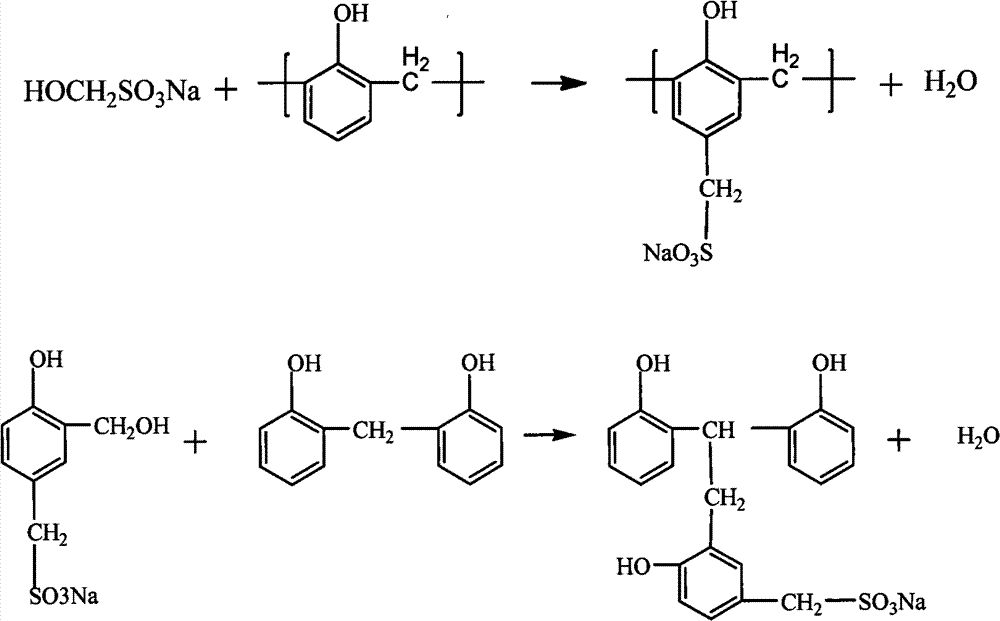

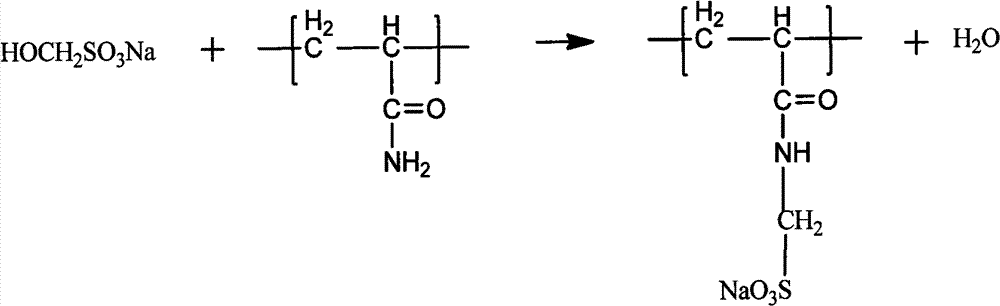

Method used

Image

Examples

Embodiment 1

[0026] Take 9g of sodium metabisulfite and 9g of sodium sulfite and add them to 90mL of water (the mass of sulfite to the volume percentage of water g / mL is 20%), add 6g of paraformaldehyde, and then pass nitrogen into the solution for 15 minutes. Then the solution is heated in a water bath at 60°C-80°C, condensed and refluxed, reacted under the condition of stirring for 3 hours, vacuum-dried at 60°C-70°C, and pulverized to obtain a high-temperature stabilizer. No phenol or aniline was added in this example.

[0027] The existing commonly used sulfonated drilling fluid formula is: 2.0% soil slurry, 0.1% Na 2 CO 3 , 1.0% NaOH, 6.0% SMP-2, 2.0% SPNH, 3.0% PSC-2, 2.0% SPC, 3.0% Tf-160, 2.0% SY-A07, 25.0% NaCl, 5.0% KCl. Then add 4.2g / m 3 High-density barite powder to a density of 2.3g / mL.

[0028] Take 300g of drilling fluid and add 3g of the prepared high-temperature stabilizer. After rolling at 160°C for 16 hours, compared with the reference sample without high-temperature ...

Embodiment 2

[0030] As described in Example 1, the difference is that the sulfite only adopts sodium sulfite.

[0031] Treat the sulfonated drilling fluid with the prepared drilling fluid high-temperature and high-salt stabilizer. After rolling at 160°C for 16 hours, the apparent viscosity decreases by 15% and the shear force decreases by 38% compared with the drilling fluid treated under the same conditions without adding it. , the amount of water loss under high temperature and high pressure did not change significantly.

Embodiment 3

[0033] As described in Example 1, the difference is that the paraformaldehyde is replaced by a 37% formaldehyde solution, and both have the same amount of effective formaldehyde.

[0034] Treat the sulfonated drilling fluid with the prepared drilling fluid high-temperature and high-salt stabilizer. After rolling at 160°C for 16 hours, compared with the drilling fluid treated under the same conditions without adding it, the apparent viscosity decreases by 18%, and the shear force decreases by 45%. , no significant change in high temperature and high pressure dehydration.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com