Long-life zinc-nickel battery and preparation method thereof

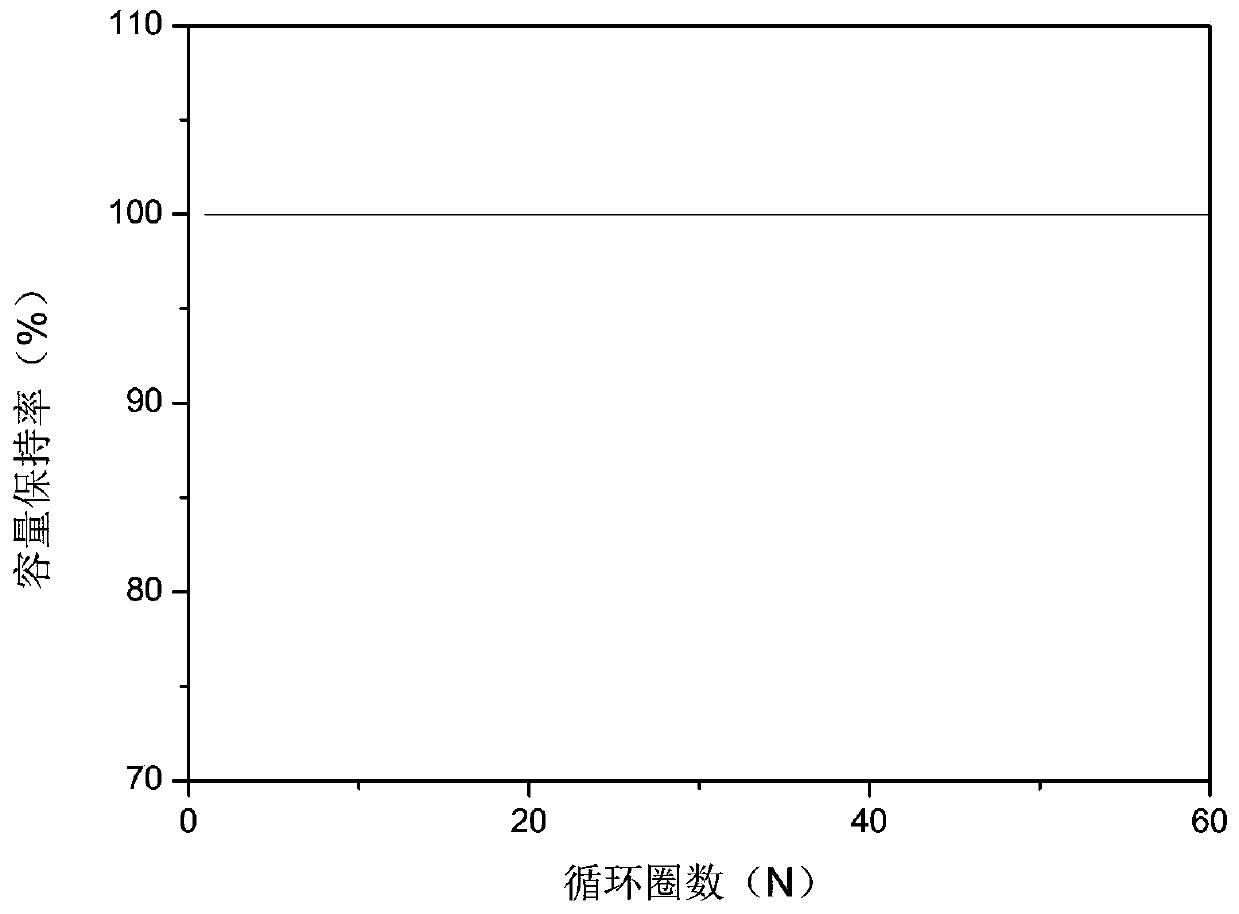

A zinc-nickel battery and electrode technology, which is applied in the field of long-life zinc-nickel battery and its preparation, can solve the problems of zinc sheet reducing material utilization, cycle life limitation, unfavorable charge transmission, etc., to achieve cycle stability improvement and battery life extension , The effect of extending battery life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040]This embodiment relates to a long-life zinc-nickel battery and a preparation method thereof, and the specific steps are as follows:

[0041] 1. Preparation of PAM-sodium alginate polymer electrolyte with high conductivity and high water retention

[0042] making process:

[0043] Step 1: Add 0.65 g of sodium alginate to 25 ml of deionized water (18.2 MΩcm) to prepare a 0.026 g / ml sodium alginate solution. At 30°C, stir magnetically for 50 min until completely dissolved.

[0044] Step 2: Add 3.5g of acrylamide, 1.75mg of N,N'-methyleneamide, and 0.035g of potassium persulfate to the above solution, and stir magnetically at 40°C for 3h. Wherein the concentration of acrylamide is 0.14g / ml, the concentration of N, N'-methyleneamide is 0.07mg / ml, and the concentration of potassium persulfate is 1.2mg / ml. N, N'-methylene amide was used as the adhesive, and potassium persulfate was used as the initiator.

[0045] The third step: the nitrogen gas was continuously passed into...

Embodiment 2

[0067] This embodiment relates to a long-life zinc-nickel battery and a preparation method thereof, and the specific steps are as follows:

[0068] 1. Preparation of PAM-sodium alginate polymer electrolyte with high conductivity and high water retention

[0069] making process:

[0070] Step 1: Add 0.5 g of sodium alginate to 20 ml of deionized water (18.2 MΩcm) to prepare a 0.025 g / ml sodium alginate solution. At 25°C, stir magnetically for 60 min until completely dissolved.

[0071] Step 2: Add 2g of acrylamide, 1.2mg of N,N'-methyleneamide, and 0.02g of potassium persulfate to the above solution, and stir magnetically at 25°C for 2h. Wherein the concentration of acrylamide is 0.1g / ml, the concentration of N, N'-methyleneamide is 0.06mg / ml, and the concentration of potassium persulfate is 1mg / ml. N, N'-methylene amide was used as the adhesive, and potassium persulfate was used as the initiator.

[0072] The third step: the nitrogen gas was continuously passed into the ab...

Embodiment 3

[0094] This embodiment relates to a long-life zinc-nickel battery and a preparation method thereof, and the specific steps are as follows:

[0095] 1. Preparation of PAM-sodium alginate polymer electrolyte with high conductivity and high water retention

[0096] making process:

[0097] Step 1: Add 0.8 g of sodium alginate to 20 ml of deionized water (18.2 MΩcm) to prepare a 0.04 g / ml sodium alginate solution. At 40°C, stir magnetically for 60 min until completely dissolved.

[0098] Step 2: Add 4g of acrylamide, 2.4mg of N,N'-methyleneamide, and 0.04g of potassium persulfate to the above solution, and stir magnetically at 40°C for 3h. Wherein the concentration of acrylamide is 0.2g / ml, the concentration of N, N'-methyleneamide is 1.2mg / ml, and the concentration of potassium persulfate is 2mg / ml. N, N'-methylene amide was used as the adhesive, and potassium persulfate was used as the initiator.

[0099] The third step: the nitrogen gas was continuously passed into the abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com