Waterborne radiation-supportive curing polyurethane acrylate combination, preparation method and coating

A technology of urethane acrylate and radiation curing, which is applied in the field of coatings and can solve problems such as sedimentation, low gloss, and weak alkalinity of neutralizers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

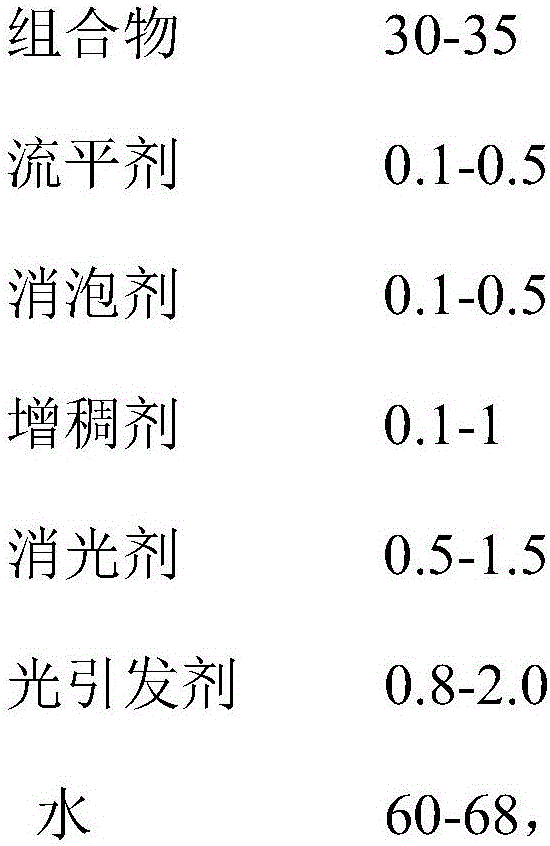

Method used

Image

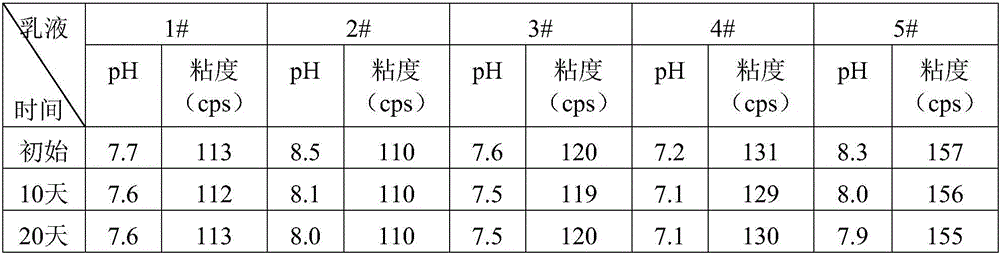

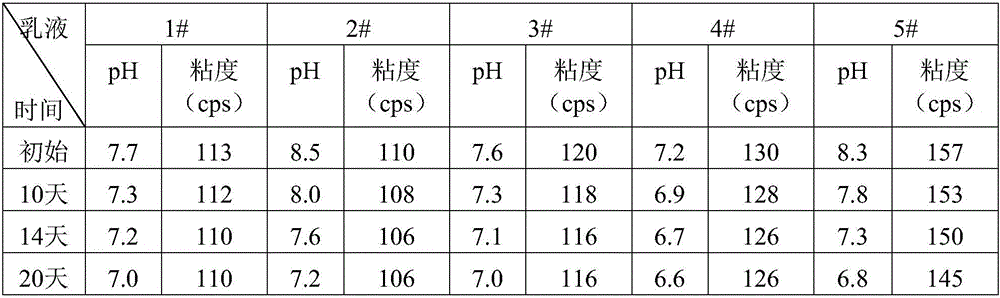

Examples

Embodiment 1

[0095] In a 2000ml four-neck flask equipped with a stirrer, condensing reflux tube, and thermocouple, add 90g HDI trimer (A1), 90g PETA (A2), 20g HEA (A2) and 5gNPG (A3), and 0.2g ethylhexanoic acid Bismuth catalyst and 0.15g polymerization inhibitor p-methoxyphenol were reacted at 80°C for 2 hours. After the content of the test-NCO group was 0.05wt%, the reaction was complete, and 160gH was added thereto. 12 MDI(B1), 100gPNA1000(B4), 30gDMPA(B2), 10gNPG(B3) and 30gPETA(B5), at the same time, in order to reduce the reaction viscosity, add 50g of acetone, react at 80°C for 2 hours, start sampling test in the reaction system- NCO group content, stop the reaction until the -NCO group content is 2.2wt%, add 200g acetone and cool down to the temperature of the reaction system reaches 40 ° C, 17.5g triethylamine (B6) is added in the reaction system, stir and neutralize for 5 Add 840g water after 2 minutes and carry out dispersion emulsification to obtain milky white emulsion, and ad...

Embodiment 2

[0097] In a 1000ml four-necked flask equipped with a stirrer, condensing reflux tube, and thermocouple, add 120g of IPDI trimer (A1) and 350g of PETA (A2), and 0.4g of bismuth octoate metal catalyst and 0.15g of inhibitor p-methoxy Phenol was reacted at 80° C. for 2 hours, and after the content of the -NCO group was tested to be 0.05 wt %, the reaction was complete to obtain polyurethane acrylic acid oligomer A for use. Another 46g of HDI (B1), 50g of PBA1000 (B4), 100g of PNA2000 (B4), 16.8g of DMPA (B2) and 30g of acetone were taken and reacted at 80°C for 2 hours, then began to take samples to test the content of -NCO groups in the reaction system until - The content of the NCO group is 1.7wt% to stop the reaction, and add the spare urethane acrylate oligomer A to mix evenly, add 200g of acetone to cool down until the temperature of the reaction system reaches 40°C, add 12.6g of triethylamine (B6) In the reaction system, after stirring and neutralizing for 5 minutes, add 10...

Embodiment 3

[0099] In a 2000ml four-necked flask equipped with a stirrer, condensing reflux tube, and thermocouple, add 97.2g HDI biuret (A1), 52.5g HEMA (A2) and 7.6g BDO (A3), and 0.13g bismuth acid catalyst and 0.1g Inhibitor p-methoxyphenol, reacted at 80°C for 2 hours, after the test-NCO group content was 0.05wt%, the reaction was complete, and 195gIPDI (B1), 190gPNA1000 (B4), 26.5gDMPA (B2) were added thereto And 175g PETA (B5), add 50g acetone in order to reduce reaction viscosity simultaneously, after reacting at 80 ℃ for 2 hours, begin to sample and test the content of -NCO group in the reaction system, stop reaction until the content of -NCO group is 2.9wt% , add 200g of acetone to cool down until the temperature of the reaction system reaches 40°C, add 14g of triethylamine (B6) into the reaction system, stir and neutralize for 5 minutes, then add 1080g of water to disperse and emulsify to obtain a milky white emulsion, and add 8.3 g of ethylenediamine (EDA) (B7) was stirred for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com