Extinctive PC/ABS (Poly Carbonate/Acrylonitrile Butadiene Styrene) plastic alloy and manufacturing method thereof

A technology of ABS plastic and plastic alloy, which is applied in the field of matting PC/ABS plastic alloy and manufacturing, to achieve the effect of low price, wide source of raw materials, and easy molding and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] In Example 1, the matting agent required by the present invention was not added.

[0020] The preparation method of the alloy material of this embodiment is specifically as follows:

[0021] 1) Weigh PC500g, ABS450g, 50g of compatibilizer, 2g of antioxidant, and 4g of lubricant for use. Among them, ABS is fully dried in advance at 80-85℃ and PC at 90-100℃ in a dryer.

[0022] 2) Add PC, ABS, and compatibilizer to a high-speed mixer and mix for 5 minutes, then add antioxidants and lubricants in sequence and mix well;

[0023] 3) The mixture obtained in step 2) is added to a co-rotating twin-screw extruder for extruding and granulating at a rotation speed of 300-400r / min and a temperature of 230-260°C. After cooling in a water tank, the mixture is cut into PC / ABS alloy materials.

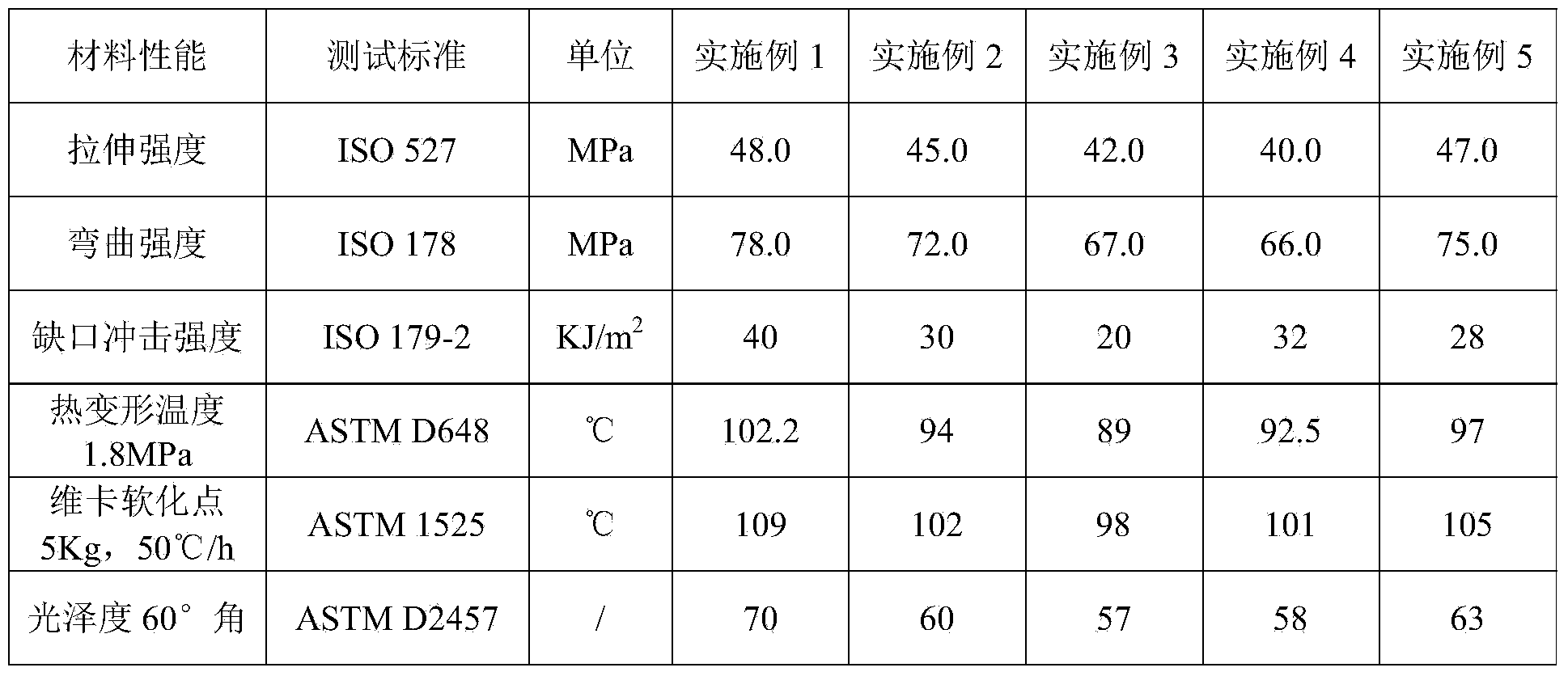

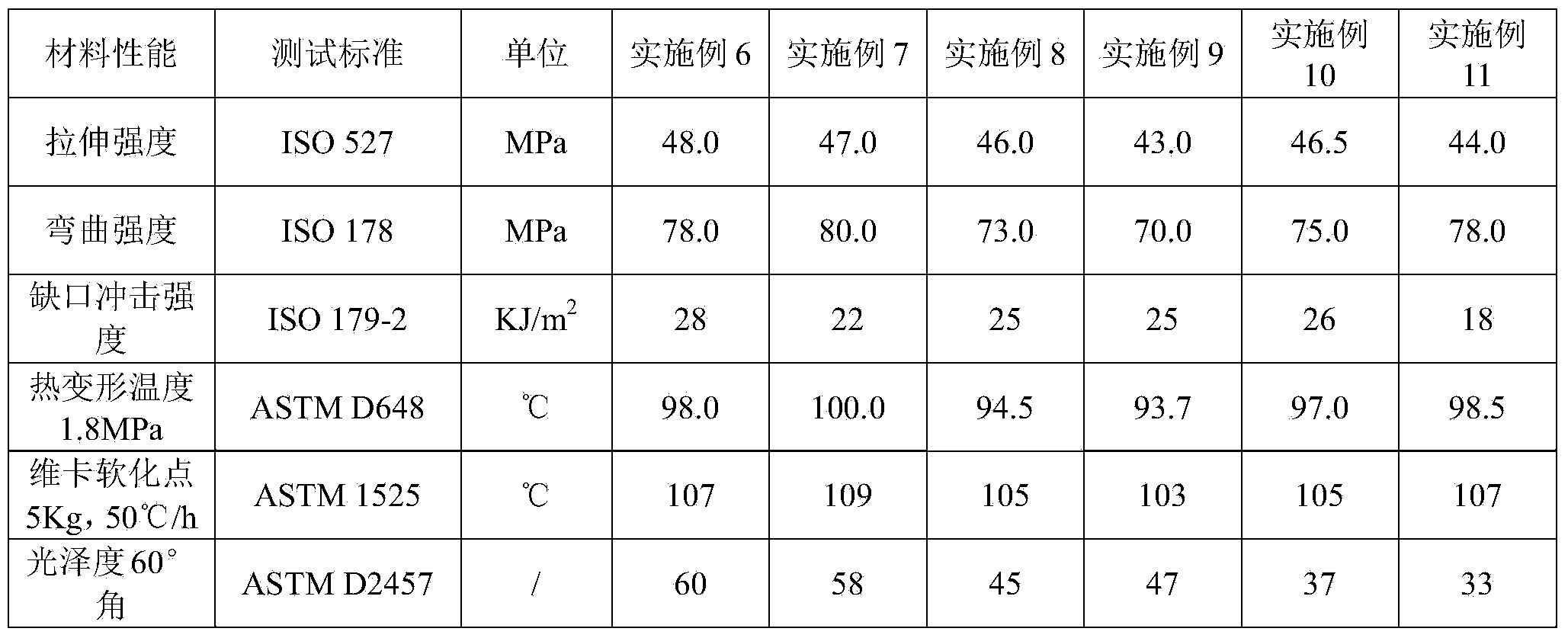

[0024] According to the preparation method of Example 1, the preparation and index analysis of the alloy materials of Examples 2-5 were performed according to the ratio of Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com