Quick-drying scratch-resistant varnish composition with high solid content as well as preparation method and application of quick-drying scratch-resistant varnish composition

A fast-drying, scratch-resistant technology used in coatings to solve problems such as high construction solids, slow initial drying of varnishes, and inability to polish and assemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

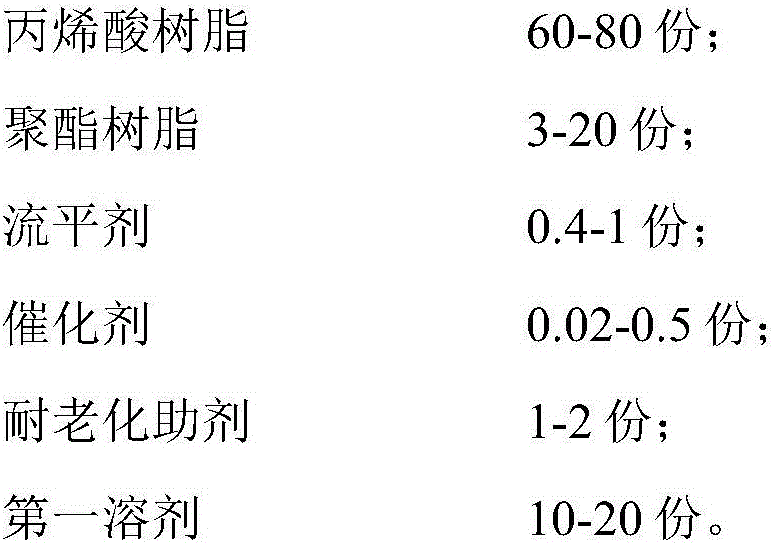

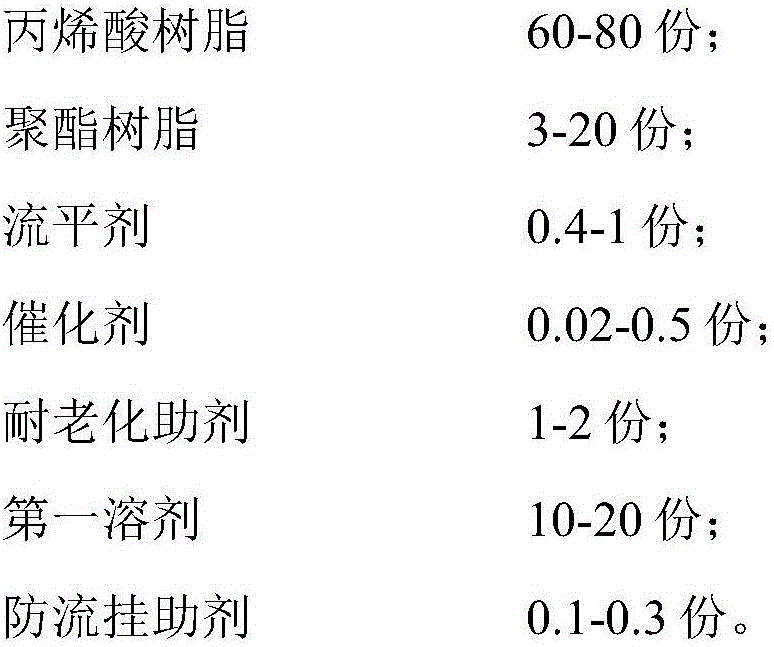

[0062] Add 7.18 parts of butyl acetate, 6 parts of methyl amyl ketone, 3 parts of methyl isobutyl ketone and 3 parts of 3-methoxy butyl propionate into a container with a stirrer. 15 parts of 75% polyester resin of Seta 1603 BA-78, 0.02 parts of dibutyltin dilaurate, 0.2 parts of dimethylethanolamine, 65 parts of Dianal LR-7928 acrylic resin with a curing amount of 75%, Tinuvin 1130 UV absorber 1.0 part of Tinuvin 292 hindered amine light stabilizer, 0.2 part of BYK 306 silicone leveling agent, 0.4 part of BYK 358N acrylate leveling agent, 0.2 part of BYK410 anti-sag additive, stir well to obtain varnish;

[0063] Under the protection of nitrogen, add 5 parts of butyl acetate, 10 parts of ethyl acetate, and 5 parts of methyl amyl ketone, stir well, use a moisture tester to test the moisture content, the moisture content is controlled at ≤0.03%, and then under stirring Add 55 parts of DESMOPHEN 3300 isocyanate and 25 parts of DESMODUR Z4470 BA isocyanate; stir evenly to obtain ...

Embodiment 2

[0066] Add 3.43 parts of butyl acetate, 6 parts of methyl amyl ketone, 3 parts of methyl isobutyl ketone and 3 parts of 3-methoxy butyl propionate into a container with a stirrer. 10 parts of polyester resin of 54% BBHA D5025 (CyglazBB500), 0.02 parts of dibutyltin dilaurate, 72 parts of Macrynal SM2810 75 BAC acrylic resin with a solid content of 75%, 1.0 parts of Tinuvin 400 UV absorber, Tinuvin 292 hindered amine 0.5 part of light stabilizer, 0.1 part of BYK 306 silicone leveling agent, 0.25 part of BYK 358N acrylate leveling agent, 0.2 part of solthix 250 rheology additive, 0.05 part of BYK 331 silicone leveling agent, stir well to obtain varnish;

[0067] Under the protection of nitrogen, add 10 parts of butyl acetate, 25 parts of ethyl acetate, and 5 parts of methyl amyl ketone, stir well, use a moisture tester to test the moisture content, the moisture content is controlled at ≤0.03%, and then under stirring Add 60 parts of DESMOPHEN 3600 isocyanate; stir evenly to obta...

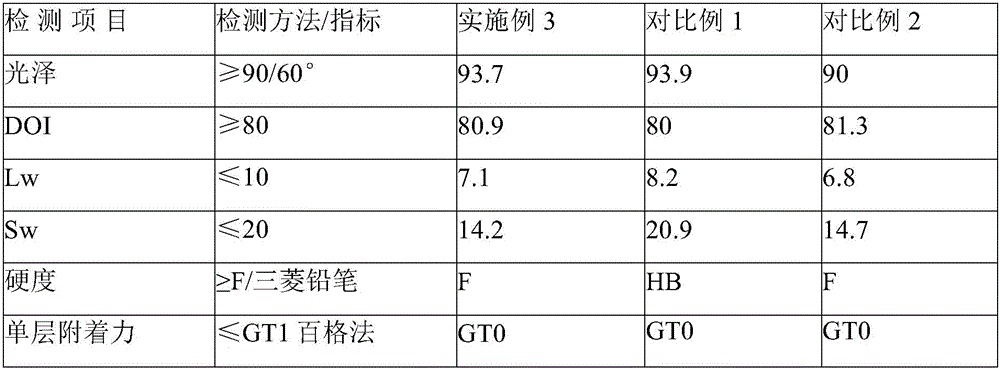

Embodiment 3

[0070] Add 4.76 parts of butyl acetate, 6 parts of methyl amyl ketone, 5 parts of methyl isobutyl ketone and 2 parts of 3-methoxy butyl propionate into a container with a stirrer. 8 parts of 62% BB 600 polyester resin, 0.02 part of dibutyltin dilaurate, 72 parts of Uracron CY 250 E-75 acrylic resin with a solid content of 75%, 1.0 part of Tinuvin 1130 UV absorber, Tinuvin 292 hindered amine light 0.5 part of stabilizer, 0.3 part of BYK 358N acrylate leveling agent, 0.1 part of EFKA 3600 fluorine-modified acrylate leveling agent, 0.04 part of Modaflow 2100 leveling agent, 0.3 part of Solthix 250 rheology additive, and stir evenly to obtain varnish;

[0071] Under nitrogen protection, add 5 parts of butyl acetate, 20 parts of ethyl acetate, 4.7 parts of S-100 solvent naphtha or trimethylbenzene solvent naphtha, 5 parts of methyl amyl ketone and 0.3 parts of ADDITIVE TI monofunctional isocyanate, and stir well , use a moisture tester to test the moisture content, the moisture con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com