Process for producing cold curing watersoluble solidifying agent of epoxy resin

A water-based epoxy resin, room temperature curing technology, applied in the chemical industry, can solve the problems of slow curing speed and long time at room temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

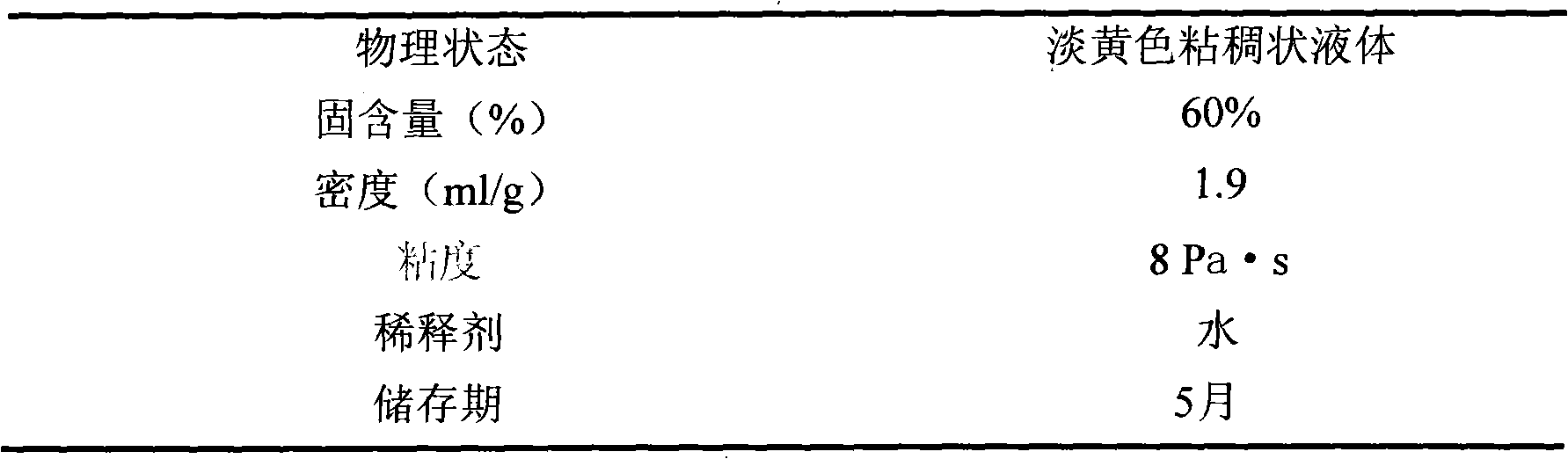

Embodiment 1

[0019] a. Capping of modified polyamine: Add 23.00g of diethylenetriamine into the reaction kettle, add 14.80g of monoepoxy 501 dropwise into the four-necked flask at a constant temperature of 60°C, and react for 3h

[0020] b. Addition of modified polyamine: add 13.80g of E-51 dropwise to the reaction kettle at a constant temperature of 60°C, and react for 4 hours.

[0021] c. Salt formation of modified polyamine: Add 35.00 kg of acetic acid dropwise to the reactor at a constant temperature of 60°C to form a salt, continue stirring for a period of time, then add water to dilute to a solid content of 60%, and stir for 1 hour.

[0022] d. Add 0.43g of DMP-30 dropwise to the reactor at a constant temperature of 60°C, stir for 0.2h, discharge, and store for later use.

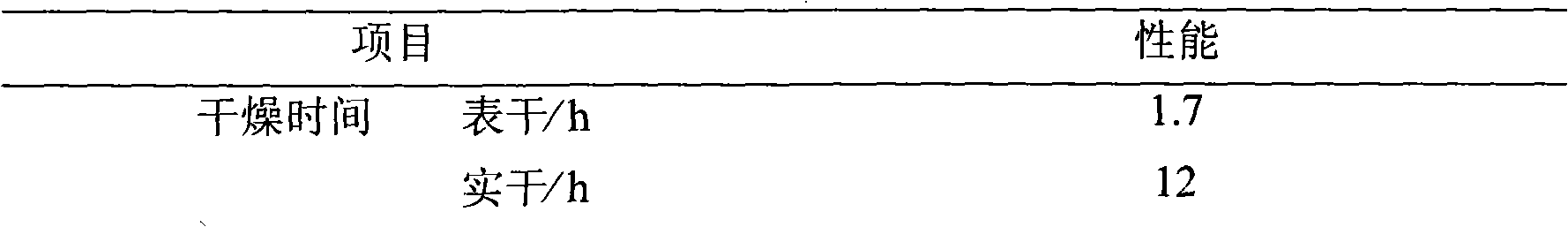

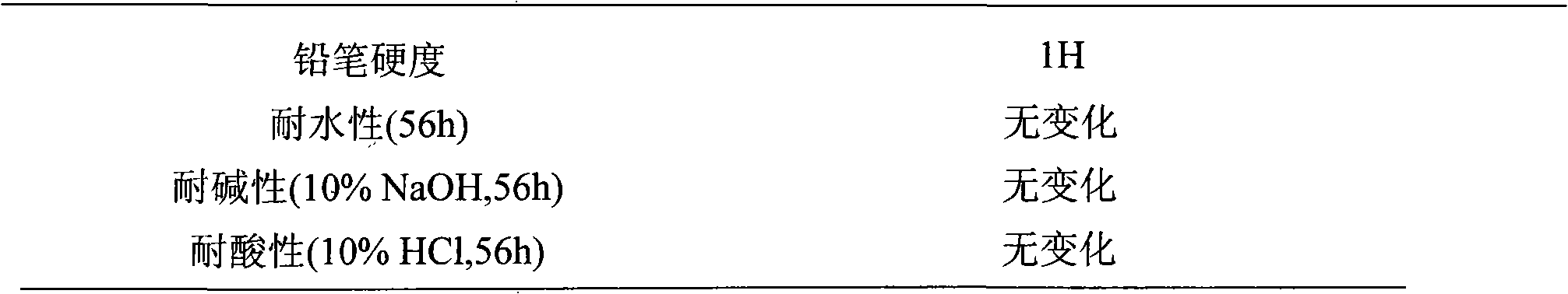

[0023] e, preparation of two-component waterborne epoxy resin paint film

[0024] A component: water-based epoxy resin curing agent B component: water-based epoxy resin emulsion

[0025] Mix according to the rat...

Embodiment 2

[0031] a. Capping of modified polyamine: Add 23.00g of diethylenetriamine into the reaction kettle, add 39.00g of monoepoxy 501 dropwise into the four-necked flask at a constant temperature of 75°C, and react for 4.5h

[0032] b. Addition of modified polyamine: add 45.00g of E-44 dropwise to the reaction kettle at a constant temperature of 75°C, and react for 6 hours.

[0033] c. Salt formation of modified polyamine: Add 7.50 g of acetic acid dropwise to the reactor at a constant temperature of 75°C to form a salt, continue stirring for a period of time, then add water to dilute to a solid content of 60%, and stir for 2 hours.

[0034] d. Finally, add 1.15 g of quaternary ammonium salt (octadecyl tertiary amine) dropwise into the reactor at a constant temperature of 75° C., stir for 0.6 h, discharge, and store for later use.

[0035] e, preparation of two-component waterborne epoxy resin paint film

[0036] A component: water-based epoxy resin curing agent B component: water-...

Embodiment 3

[0042] a. Capping of modified polyamine: Add 23.00 g of diethylenetriamine into the reaction kettle, add 22.00 g of monoepoxy 501 dropwise into the four-necked flask at a constant temperature of 90° C., and react for 6 hours.

[0043] b. Addition of modified polyamine: add 28.00g of E-20 dropwise to the reaction kettle at a constant temperature of 90°C, and react for 8 hours.

[0044] c. Salt formation of modified polyamine: Add 21.50 g of acetic acid dropwise to the reactor at a constant temperature of 90°C to form a salt, continue to stir for a period of time, then add water to dilute to a solid content of 60%, and stir for 3 hours.

[0045] d. Finally, add 1.89 g of boron trifluoride amine complex dropwise into the reactor at a constant temperature of 90° C., stir for 1 hour, discharge, and store for later use.

[0046] e, preparation of two-component waterborne epoxy resin paint film

[0047] A component: water-based epoxy resin curing agent B component: water-based epoxy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com