Preparing method of high-densification ultra-fine grain large-size molybdenum target

An ultra-fine-grained, large-size technology, applied in metal material coating process, vacuum evaporation plating, coating, etc., can solve the problems of insufficient density, particle splashing, coarse grains of molybdenum billet metal, etc., to improve the thin film performance, increased sputtering speed, and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

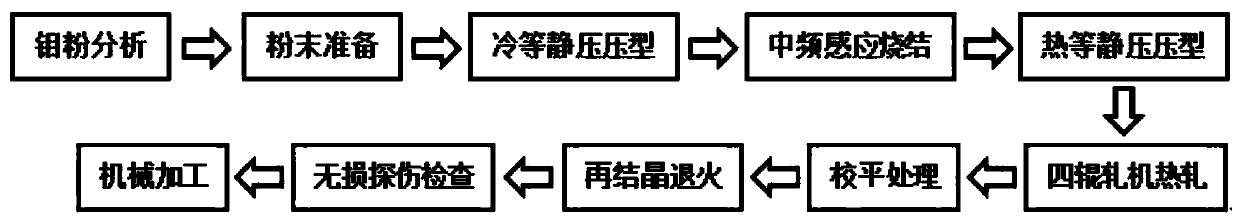

[0043] A method for preparing a high-density ultra-fine-grained large-size molybdenum target provided by the present invention comprises the following steps:

[0044] (1) cold isostatic pressing type

[0045] Select molybdenum powder, put the prepared molybdenum powder into the mold, and then put it into the cold isostatic pressing equipment for cold isostatic pressing, and obtain the cold isostatic pressing green body after pressure relief;

[0046] Preferably, the molybdenum content of the molybdenum powder is ≥99.95%, which meets the national standard GB / T3461-2006. The Fischer particle size is 3.0-3.8μm and the bulk density is 4.0-8.0g / cm 3 , and use a standard sieve to filter out the molybdenum powder with large particle size before using the molybdenum powder.

[0047] Preferably, the density of the cold isostatic pressed body after cold isostatic pressing is not lower than 40%.

[0048] (2) Sintering

[0049] The cold isostatic pressed green body is sintered by inducti...

Embodiment 1

[0072] The specifications of the finished molybdenum target prepared in the embodiment of the present invention are: length 3430 mm, width 400 mm, thickness 18 mm.

[0073] Such as figure 1 As shown, the preparation method of a high-density ultra-fine-grained large-size molybdenum target provided by the embodiment of the present invention includes the following steps:

[0074] (1) Molybdenum powder analysis and powder preparation

[0075] Use ICP atomic absorption spectrometer and carbon-oxygen analyzer to analyze the purity of molybdenum powder, requiring Mo content ≥ 99.5%, and controlling the content of impurity elements in the following range:

[0076] C<0.003; O<0.1; N<0.001; S<0.001; Fe<0.003; Sn<0.0005; Ni<0.003; Sb<0.01; Si<0.002; Cd<0.0005; Al<0.001; 0.002; Cu<0.001; W<0.02; Pb<0.0005; Bi<0.0005.

[0077] The particle size standard meets GB / T3461-2006 national standard, the Fischer particle size is 3.0-3.8μm, and the bulk density is 4.0-8.0g / cm 3 . Select molybde...

Embodiment 2

[0100] The specifications of the finished molybdenum target prepared in the embodiment of the present invention are: length 2300 mm, width 1800 mm, thickness 14 mm.

[0101] A method for preparing a high-density ultra-fine-grained large-size molybdenum target provided by an embodiment of the present invention includes the following steps:

[0102] (1) Molybdenum powder analysis and powder preparation

[0103] Use ICP atomic absorption spectrometer and carbon-oxygen analyzer to analyze the purity of molybdenum powder, requiring Mo content ≥ 99.5%, and controlling the content of impurity elements in the following range:

[0104] C<0.003; O<0.1; N<0.001; S<0.001; Fe<0.003; Sn<0.0005; Ni<0.003; Sb<0.01; Si<0.002; Cd<0.0005; Al<0.001; 0.002; Cu<0.001; W<0.02; Pb<0.0005; Bi<0.0005.

[0105] The particle size standard meets GB / T3461-2006 national standard, the Fischer particle size is 3.0-3.8μm, and the bulk density is 4.0-8.0g / cm 3 . Select molybdenum powder with a median value ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com