Method for preparing Cu3SnS4 through binding-single-target sputtering

An absorption layer and sputtering technology, applied in the field of binding single target sputtering to prepare Cu3SnS4 absorption layer, can solve the problems of reducing the number of targets, poor conductivity, discharge of the target, etc. And the effect of uniform composition and fast sputtering speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

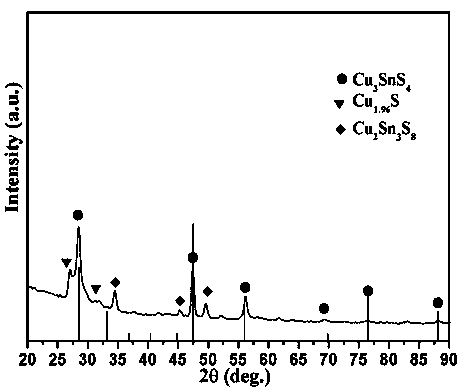

[0026] Example 1: Preparation of Cu by sputtering with a bound single target 3 SnS 4 The method of absorbing layer, concrete steps are:

[0027] (1) Substrate pretreatment: The soda-lime glass substrate is ultrasonically cleaned with acetone, absolute ethanol, and deionized water in sequence, and the cleaned substrate is dried with nitrogen gas, and placed on a substrate rack filled with absolute ethanol For use, blow dry the substrate with nitrogen;

[0028] (2) Place the pretreated substrate in step (1) on the sample holder in the magnetron sputtering chamber, install the ternary copper-tin-sulfur target bound to the pure copper target in the magnetron sputtering chamber, adjust the binding The target base distance between the ternary copper-tin-sulfur target of the pure copper target and the substrate in the sputtering chamber is 80 mm; the ternary copper-tin-sulfur target bound to the pure copper target is the ternary copper-tin-sulfur target through The indium material...

Embodiment 2

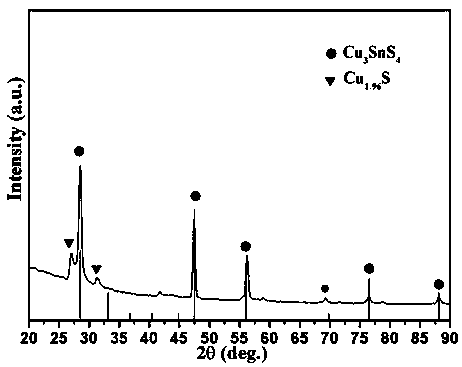

[0033] Example 2: Preparation of Cu by sputtering with a single bound target 3 SnS 4 The method of absorbing layer, concrete steps are:

[0034] (1) Substrate pretreatment: The soda-lime glass substrate is ultrasonically cleaned with acetone, absolute ethanol, and deionized water in sequence, and the cleaned substrate is dried with nitrogen gas, and placed on a substrate rack filled with absolute ethanol For use, blow dry the substrate with nitrogen;

[0035] (2) Place the pretreated substrate in step (1) on the sample holder in the magnetron sputtering chamber, install the ternary copper-tin-sulfur target bound to the pure copper target in the magnetron sputtering chamber, adjust the binding The target base distance between the ternary copper-tin-sulfur target of the pure copper target and the substrate in the sputtering chamber is 85 mm; the ternary copper-tin-sulfur target bound to the pure copper target is the ternary copper-tin-sulfur target through The indium material...

Embodiment 3

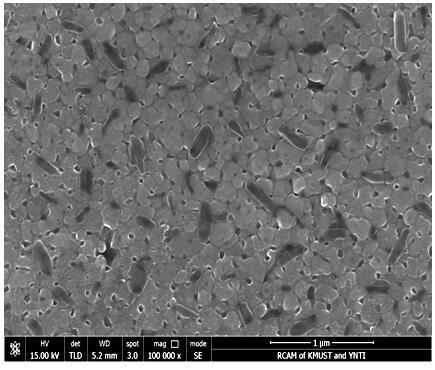

[0042] Example 3: Preparation of Cu by sputtering with a bound single target 3 SnS 4 The method of absorbing layer, concrete steps are:

[0043] (1) Substrate pretreatment: The soda-lime glass substrate is ultrasonically cleaned with acetone, absolute ethanol, and deionized water in sequence, and the cleaned substrate is dried with nitrogen gas, and placed on a substrate rack filled with absolute ethanol For use, blow dry the substrate with nitrogen;

[0044] (2) Place the pretreated substrate in step (1) on the sample holder in the magnetron sputtering chamber, install the ternary copper-tin-sulfur target bound to the pure copper target in the magnetron sputtering chamber, adjust the binding The target base distance between the ternary copper-tin-sulfur target of the pure copper target and the substrate in the sputtering chamber is 90 mm; the ternary copper-tin-sulfur target bound to the pure copper target is the ternary copper-tin-sulfur target through The indium material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com