A bound single-target sputtering preparation of Cu 3 sns 4 method of absorbing layer

An absorption layer and sputtering technology, which is applied in the field of Cu3SnS4 absorption layer prepared by sputtering with a single target, can solve the problems of target reduction, poor conductivity, target discharge, etc. And the effect of uniform composition and fast sputtering speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

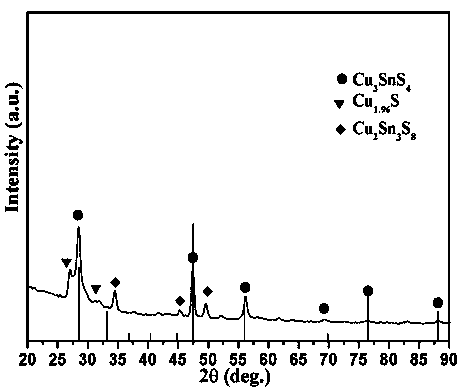

Embodiment 1

[0026] Example 1: Preparation of Cu by sputtering with a bound single target 3 SnS 4 The method of absorbing layer, concrete steps are:

[0027] (1) Substrate pretreatment: The soda-lime glass substrate is ultrasonically cleaned with acetone, absolute ethanol, and deionized water in sequence, and the cleaned substrate is dried with nitrogen gas, and placed on a substrate rack filled with absolute ethanol For use, blow dry the substrate with nitrogen;

[0028] (2) Place the pretreated substrate in step (1) on the sample holder in the magnetron sputtering chamber, install the ternary copper-tin-sulfur target bound to the pure copper target in the magnetron sputtering chamber, adjust the binding The target base distance between the ternary copper-tin-sulfur target of the pure copper target and the substrate in the sputtering chamber is 80 mm; the ternary copper-tin-sulfur target bound to the pure copper target is the ternary copper-tin-sulfur target through The indium material...

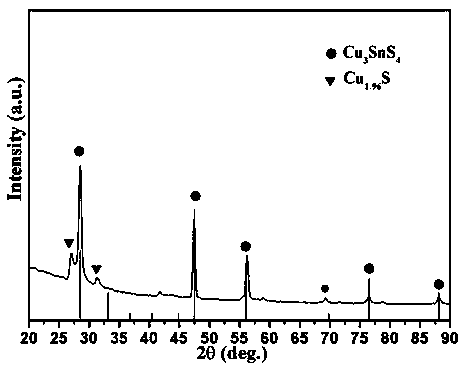

Embodiment 2

[0033] Example 2: Preparation of Cu by sputtering with a single bound target 3 SnS 4 The method of absorbing layer, concrete steps are:

[0034] (1) Substrate pretreatment: The soda-lime glass substrate is ultrasonically cleaned with acetone, absolute ethanol, and deionized water in sequence, and the cleaned substrate is dried with nitrogen gas, and placed on a substrate rack filled with absolute ethanol For use, blow dry the substrate with nitrogen;

[0035] (2) Place the pretreated substrate in step (1) on the sample holder in the magnetron sputtering chamber, install the ternary copper-tin-sulfur target bound to the pure copper target in the magnetron sputtering chamber, adjust the binding The target base distance between the ternary copper-tin-sulfur target of the pure copper target and the substrate in the sputtering chamber is 85 mm; the ternary copper-tin-sulfur target bound to the pure copper target is the ternary copper-tin-sulfur target through The indium material...

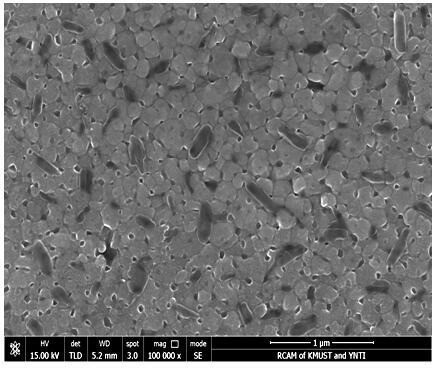

Embodiment 3

[0042] Example 3: Preparation of Cu by sputtering with a bound single target 3 SnS 4 The method of absorbing layer, concrete steps are:

[0043] (1) Substrate pretreatment: The soda-lime glass substrate is ultrasonically cleaned with acetone, absolute ethanol, and deionized water in sequence, and the cleaned substrate is dried with nitrogen gas, and placed on a substrate rack filled with absolute ethanol For use, blow dry the substrate with nitrogen;

[0044] (2) Place the pretreated substrate in step (1) on the sample holder in the magnetron sputtering chamber, install the ternary copper-tin-sulfur target bound to the pure copper target in the magnetron sputtering chamber, adjust the binding The target base distance between the ternary copper-tin-sulfur target of the pure copper target and the substrate in the sputtering chamber is 90 mm; the ternary copper-tin-sulfur target bound to the pure copper target is the ternary copper-tin-sulfur target through The indium material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com