High weld mark strength reinforced polypropylene material and preparation method thereof

A polypropylene material and polypropylene resin technology, which is applied in the field of polymer material molding and processing, can solve problems such as increasing product cost and increasing equipment investment, and achieves the effects of improving weld line strength and dispersion phase viscosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

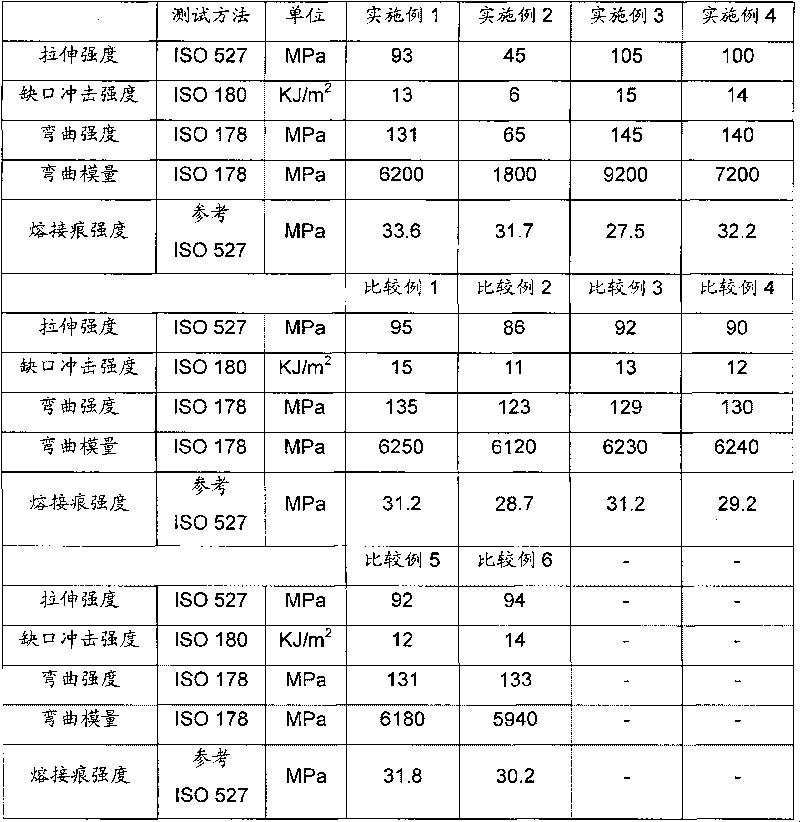

Examples

Embodiment 1

[0021] Add 62% homopolypropylene resin with a melt index of 30g / 10min (230°C, 2.16KG), 2.5% PP-g-KH550 (KH550 is an aminosilane coupling agent) and 0.5% other Mixture of additives, 5% wollastonite surface-treated by KH550 is added to the first side feeding port, and 30% glass fiber surface-treated by KH550 is added to the second side feeding port. After melting and blending in a twin-screw extruder, it is cooled, air-dried, and pelletized into pellets. The pellets were injection molded into weld line strength test specimens for testing.

Embodiment 2

[0023] Add 87% copolymerized polypropylene resin with a melt index of 80g / 10min (230°C, 2.16KG) and 2.5% PP-g-(SG-Si 151) (SG-Si 151 is a vinyl silane) from the main feed port coupling agent) and 0.5% other additives, add 5% barium sulfate surface-treated by KH550 to the first side feed port, and add 5% glass fiber surface-treated by KH550 to the second side feed port. After melting and blending in a twin-screw extruder, it is cooled, air-dried, and pelletized into pellets. The pellets were injection molded into weld line strength test specimens for testing.

Embodiment 3

[0025] Add 35% homopolypropylene resin with a melt index of 3g / 10min (230°C, 2.16KG) and 10% PP-g-(S-3046) (S-3046 is an azidosilane) from the main feed port coupling agent) and 4% other additives, add 1% wollastonite surface-treated by KH550 to the first side feeding port, and add 50% glass fiber surface-treated by KH550 to the second side feeding port. After melting and blending in a twin-screw extruder, it is cooled, air-dried, and pelletized into pellets. The pellets were injection molded into weld line strength test specimens for testing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com