Electret master batch for melt-blown non-woven fabric for low-resistance mask and preparation method of electret master batch

A technology of melt-blown non-woven fabrics and low resistance, which is applied in the direction of non-woven fabrics, textiles and papermaking, etc. It can solve problems such as difficulties and complex work of adjusting the process, and achieve the effects of low breathing resistance, easy implementation, and high filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~2

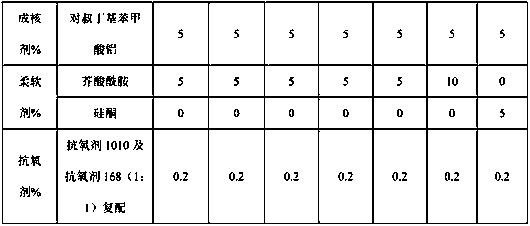

[0043] Examples 1~2 and Comparative Examples 1~4

[0044] According to the formula in Table 1, the materials are mixed in a high-speed mixer, and then melt-blended and extruded through a twin-screw extruder with a length-to-diameter ratio of 40:1. The temperature of the melting section is 150-210℃ to obtain a meltblown non-woven fabric for masks. Use electret masterbatch.

[0045] Table 1

[0046]

Embodiment 3~8 and comparative example 5

[0055] According to the formula in Table 3, the materials are mixed in a high-speed mixer, and then melt-blended and extruded through a twin-screw extruder with a length-to-diameter ratio of 48:1. The temperature of the melting section is 150-210°C to obtain a meltblown non-woven fabric for mask Use electret masterbatch.

[0056] table 3

[0057]

[0058]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com