Catalyst component for olefinic polymerization , and catalyst thereof

A technology of olefin polymerization and catalyst, which is applied in the field of spherical catalyst components and catalysts, and can solve problems that need to be further improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

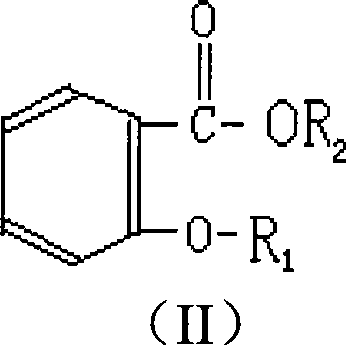

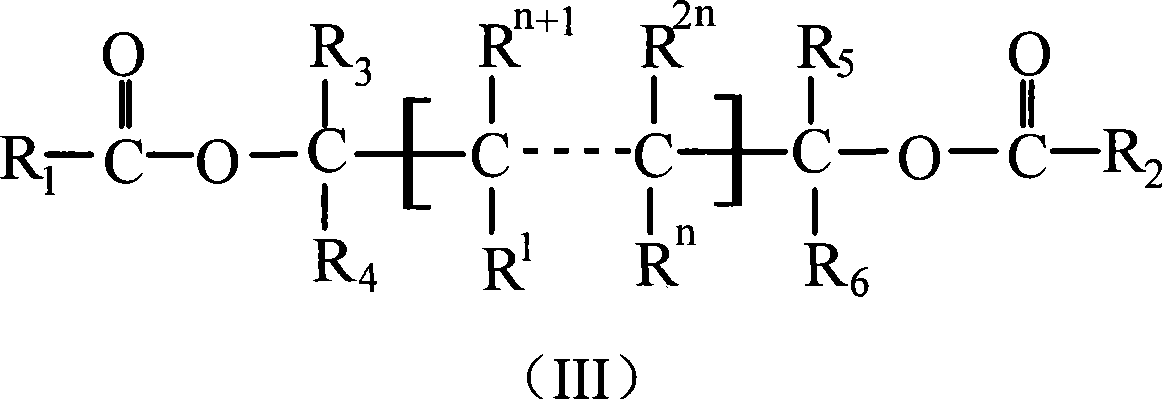

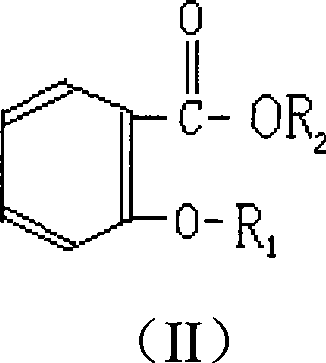

Method used

Image

Examples

Embodiment 1

[0063] A. Vector preparation

[0064] In a 0.5L autoclave, add 150ml of white oil, 30g of magnesium chloride, 50ml of ethanol and 3ml of o-methoxybenzoyl chloride. The temperature is raised to 125°C with stirring, and the mixture is stirred at 125°C for 2.5 hours. The mixture is placed at 120°C. In the silicone oil, stir for 45 minutes, then put it into 2L of hexane that was pre-cooled to -30°C, filter off the liquid, wash the solid with hexane five times, and vacuum dry to obtain 50 g of spherical magnesium chloride adduct carrier.

[0065] B. Preparation of catalyst

[0066] In a 300ml glass reaction flask, add 100ml of titanium tetrachloride, cool to -20°C, add 8 grams of the above spherical magnesium chloride adduct, heat up to 110°C, and add diisobutyl phthalate during the heating process 1.5ml, filtered off the liquid, washed twice with titanium tetrachloride, washed three times with hexane, and dried in vacuum to obtain a spherical catalyst.

[0067] C. Propylene polymeriza...

Embodiment 2

[0070] Same as in Example 1 except 5.0L hydrogen for propylene polymerization.

Embodiment 3

[0072] Same as in Example 1 except 8.0L of hydrogen for propylene polymerization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com