Biomass hydrothermal pretreatment reactor

A biomass and reactor technology, applied in the field of biomass pretreatment reactors, can solve problems such as the lack of much progress in the development of reactors, and achieve the effects of reducing side reactions, increasing flexibility, and enhancing applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

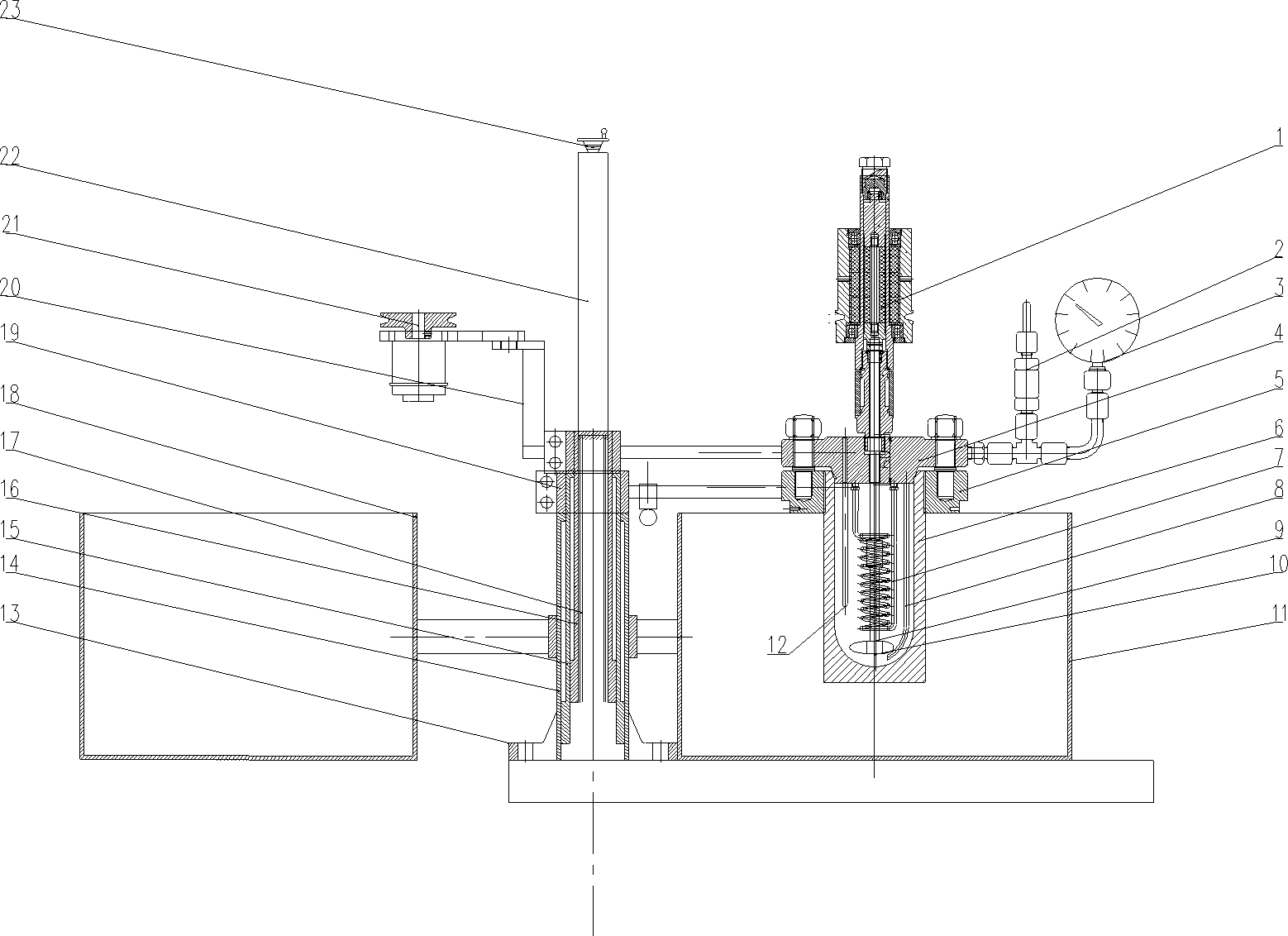

[0020] as attached figure 1 After adding the corn stalks into the reaction kettle (6), according to the requirement of adjusting the water content, a certain amount of tap water is added to adjust the water content of the material to 92% (w / w). Cover the kettle cover (4), tighten the bolts on the flange (5), and insert the temperature sensor probe into the temperature measuring tube (12). Turn on the magnetic stirring system (1), drive the stirring paddle (10) - the six curved blades turn on the turbine type, and control the stirring speed at 50rpm, so that the materials and water are evenly mixed. After shaking the handle (23), the lifting fixed sleeve 1 (15), the lifting fixed sleeve 2 (16) and the lifting screw (17) to the top of the oil bath (11) that has risen to 250 ° C, then use the lifting screw to shake the handle ( 23), the lifting fixed sleeve 1 (15), the lifting fixed sleeve 2 (16) and the lifting screw (17) slowly put the reactor into the oil bath. When the temp...

Embodiment 2

[0023] as attached figure 1 After adding the corn stalks into the reaction kettle (6), according to the requirement of adjusting the water content, a certain amount of tap water is added to adjust the water content of the material to 85% (w / w). Cover the kettle cover (4), tighten the bolts on the flange (5), and insert the temperature sensor probe into the temperature measuring tube (12). Turn on the magnetic stirring system (1), drive the stirring paddle (10) - Bruma gold type, and control the stirring speed at 80rpm, so that the material and water are evenly mixed. After shaking the handle (23), the lifting fixed cover 1 (15), the lifting fixed cover 2 (16) and the lifting screw (17) to the top of the oil bath (11) that has risen to 300 ° C, then use the lifting screw to shake the handle ( 23), the lifting fixed sleeve 1 (15), the lifting fixed sleeve 2 (16) and the lifting screw (17) slowly put the reactor into the oil bath. When the temperature of the reaction kettle ros...

Embodiment 3

[0026] as attached figure 1After adding the corn stalks into the reaction kettle (6), according to the requirement of adjusting the water content, a certain amount of tap water is added to adjust the water content of the material to 80% (w / w). Cover the kettle cover (4), tighten the bolts on the flange (5), and insert the temperature sensor probe into the temperature measuring tube (12). Turn on the magnetic stirring system (1), drive the stirring paddle (10) - three-blade propulsion type, and control the stirring speed at 60rpm, so that the materials and water are evenly mixed. After shaking the handle (23), the lifting fixed cover 1 (15), the lifting fixed cover 2 (16) and the lifting screw (17) to the top of the oil bath (11) that has risen to 350 ° C, then use the lifting screw to shake the handle ( 23), the lifting fixed sleeve 1 (15), the lifting fixed sleeve 2 (16) and the lifting screw (17) slowly put the reactor into the oil bath. When the temperature of the reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com