CoFeMOF-P/b-CNF composite material electrocatalyst and preparation method thereof

A technology of electrocatalysts and composite materials, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of scarcity, high cost, and limited large-scale use , to achieve the effects of environmental friendliness, improved electrocatalytic performance, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

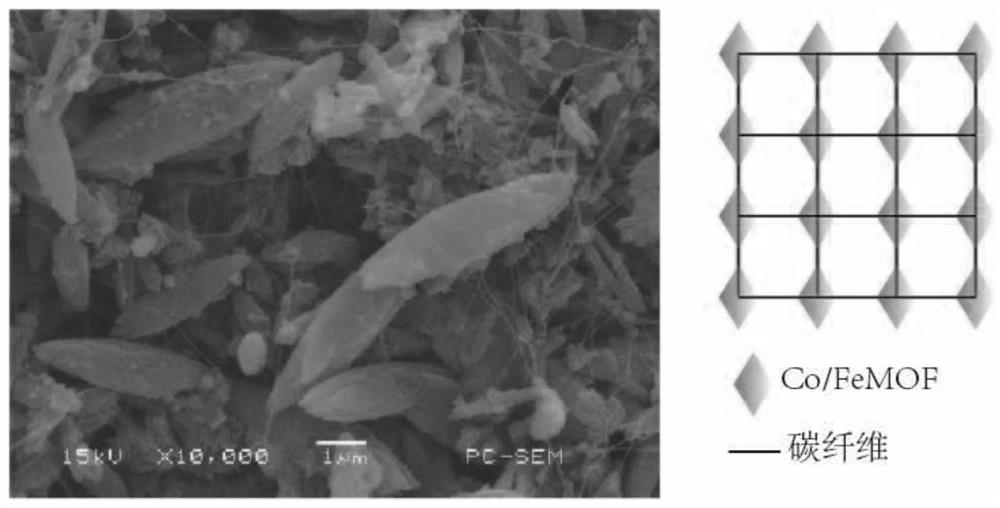

[0030] Example 1: A CoFeMOF-P / b-CNF composite electrocatalyst and its preparation method

[0031] A CoFeMOF-P / b-CNF composite electrocatalyst, the CoFeMOF-P / b-CNF electrocatalyst includes Co salt, Fe salt and bacterial cellulose membrane, and the CoFeMOF-P / b-CNF electrocatalyst is subjected to high temperature through phosphorus salt Phosphating.

[0032] Its preparation method is as follows:

[0033] S1. Prepare 10 mL of a mixed solution of N,N-dimethylformamide (DMF) and ethanol at a volume ratio of 1:1, and add 11 mg / mL of Co(CH 3 COO) 2 •6H 2 O, 6 mg / mL FeCl 3 •6H 2 O, 6 mg / mL terephthalic acid and 50 mg / mL polyvinylpyrrolidone were dissolved evenly at room temperature, then 1 g of bacterial cellulose membrane was added, shaken and adsorbed for 12 hours, and transferred to a polytetrafluoroethylene reactor , heated to 150°C for hydrothermal reaction for 48 hours; after cooling to room temperature, washed with DMF three times, and dried the brown-black product in an o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com