Powdered composite calcium zinc stabilizing agent and preparation method thereof

A technology of composite calcium zinc and stabilizer, which is applied in the field of stabilizer preparation, can solve problems such as poor compatibility and poor coloring, and achieve the effect of improving thermal stability and inhibiting degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

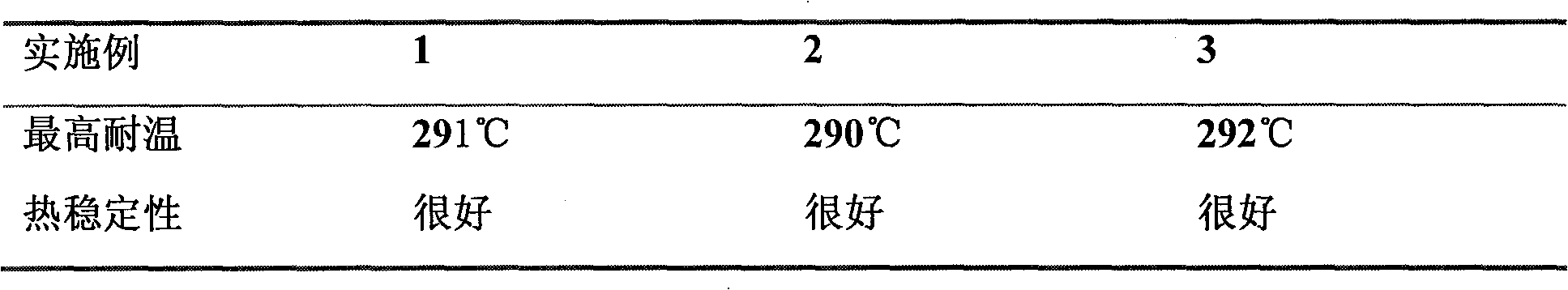

Embodiment 1

[0022] Example 1: Efficient Powder Composite Calcium-Zinc Stabilizer

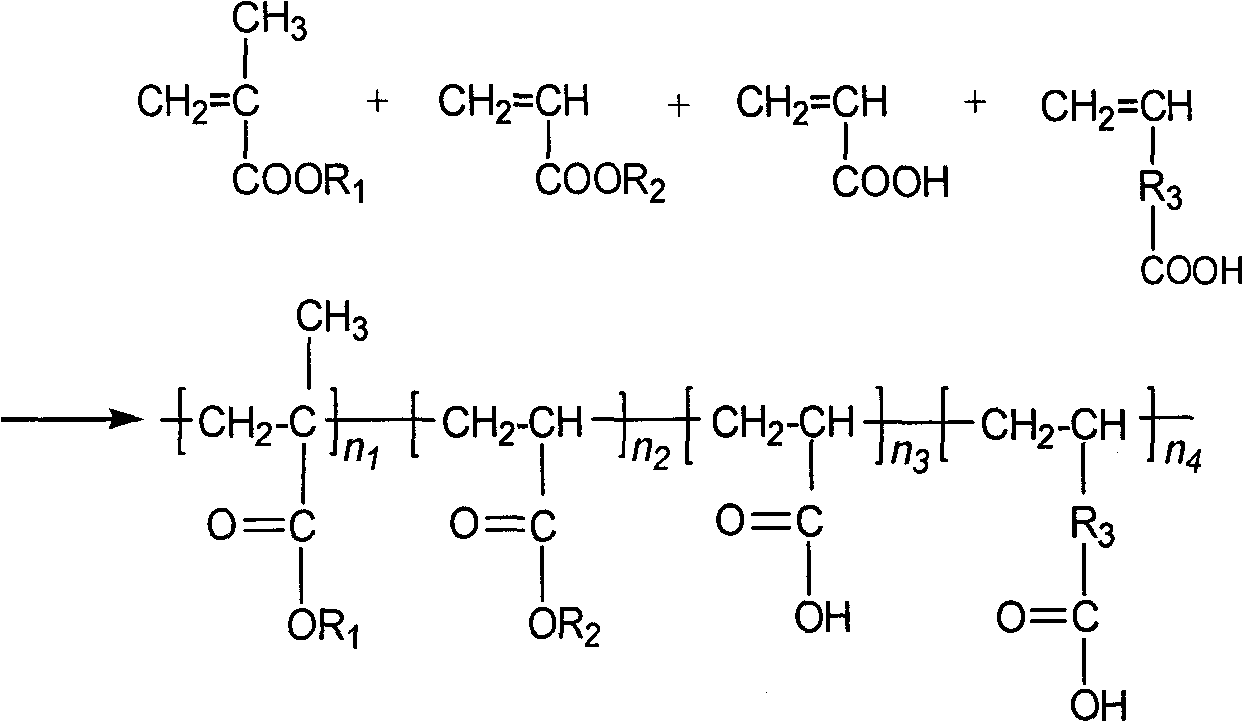

[0023] 1. Preparation of acrylic acid functionalized polyfatty acid resin

[0024] In the reaction tank, add 893kg of oleic acid, and slowly heat up under constant stirring. When the temperature rises to 65°C, add 180kg of polyfatty acid resin, 150kg of calcium hydroxide, 100kg of zinc oxide, and 950kg of higher alcohol to carry out a salt-forming reaction, stir and keep warm, and keep the temperature at 65-70°C under normal pressure Keep warm for two hours. Pour the contents of the reaction tank into the drain tank.

[0025] 2. Preparation of high-purity epoxy fatty acid calcium

[0026] In the reaction tank, add 1786kg of oleic acid, and slowly heat up under constant stirring. When the temperature rises to 55-65°C, stop heating, add 200kg of glacial acetic acid and 30kg of concentrated sulfuric acid. Begin to drip hydrogen peroxide 1040kg. Control the rate of addition, the dropwise addition is compl...

Embodiment 2

[0029] Example 2: High-efficiency powder composite calcium-zinc stabilizer

[0030] 1. Preparation of acrylic acid functionalized polyfatty acid resin

[0031] In the reaction tank, add 129kg of oleic acid once, and slowly heat up under uniform stirring. When the temperature rises to 60°C, add 17.5kg of polyfatty acid resin, 15.6kg of calcium hydroxide, 10.5kg of zinc oxide, and 94kg of higher alcohol for salt-forming reaction, stir and keep warm, and keep the temperature at 65-70°C. Press down and keep warm for 3 hours. Pour the contents of the reaction tank into the drain tank.

[0032] 2. Preparation of high-purity epoxy fatty acid calcium

[0033] In the reaction tank, add 258kg of oleic acid, and slowly heat up under constant stirring. When the temperature rises to 55-65°C, stop heating, add 20.6kg of glacial acetic acid and 3kg of concentrated sulfuric acid. Begin to drip hydrogen peroxide 104kg. Control the rate of addition, the dropwise addition is completed in a...

Embodiment 3

[0036] Example 3: Efficient Powder Composite Calcium-Zinc Stabilizer

[0037] 1. Preparation of acrylic acid functionalized polyfatty acid resin

[0038] In the reaction tank, the oleic acid of 155kg was added once, and the temperature was slowly raised under uniform stirring. When the temperature rises to 55°C, add 21kg of polyfatty acid resin, 18.72kg of calcium hydroxide, 12.6kg of zinc oxide, and 112.8kg of higher alcohol to carry out a salt-forming reaction, stir and keep warm, and keep the temperature at 65-70°C. Constant temperature under normal pressure for two hours. Pour the contents of the reaction tank into the drain tank.

[0039] 2. Preparation of high-purity epoxy fatty acid calcium

[0040] In the reaction tank, add 213kg of oleic acid, and slowly heat up under constant stirring. When the temperature rises to 55-65°C, stop heating, add 24.72kg of glacial acetic acid and 3.6kg of concentrated sulfuric acid. Begin to drip hydrogen peroxide 125kg. Control th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com