Resin abrasive wheel containing teflon dry-grinding lubricant agent and manufacturing method thereof

A technology of polytetrafluoroethylene and polytetrafluoroethylene powder, applied in the field of resin grinding wheel and its manufacturing method, to achieve the effects of increasing self-sharpening, improving durability, and excellent chemical corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0045] Select the bonding mixed abrasive of the following ratio, and its ratio by weight percentage is:

[0046] 24# brown corundum abrasive 40%

[0047] 30# brown corundum abrasive 37%

[0048] Phenolic resin solution 5%

[0049] 240 mesh phenolic resin powder 10%

[0050] 120 mesh ice crystal 7%

[0051] PTFE powder (average particle size 5μm) 1%

[0052] Its preparation process is as follows:

[0053] Put 24# and 30# brown corundum into the mixing pot according to the proportion and weight to mix evenly, then add phenolic resin solution, after the corundum abrasive is completely wetted, add cryolite and polytetrafluoroethylene powder in turn, mix well and then put in phenolic resin The powder continues to mix until the phenolic resin powder is evenly attached to each abrasive. Then weigh according to the single weight of the cutting piece and then feed the material. Before feeding, put the grinding wheel mesh, spread the material with a scraper, put a grinding wheel m...

example 2

[0056] Select the bonding mixed abrasive of the following ratio, and its ratio by weight percentage is:

[0057] 30# brown corundum abrasive 41%

[0058] 36# brown corundum abrasive 34%

[0059] Phenolic resin solution 5%

[0060] 240 mesh phenolic resin powder 10%

[0061] 120 mesh ice crystal 5%

[0062] PTFE powder (average particle size 5μm) 5%

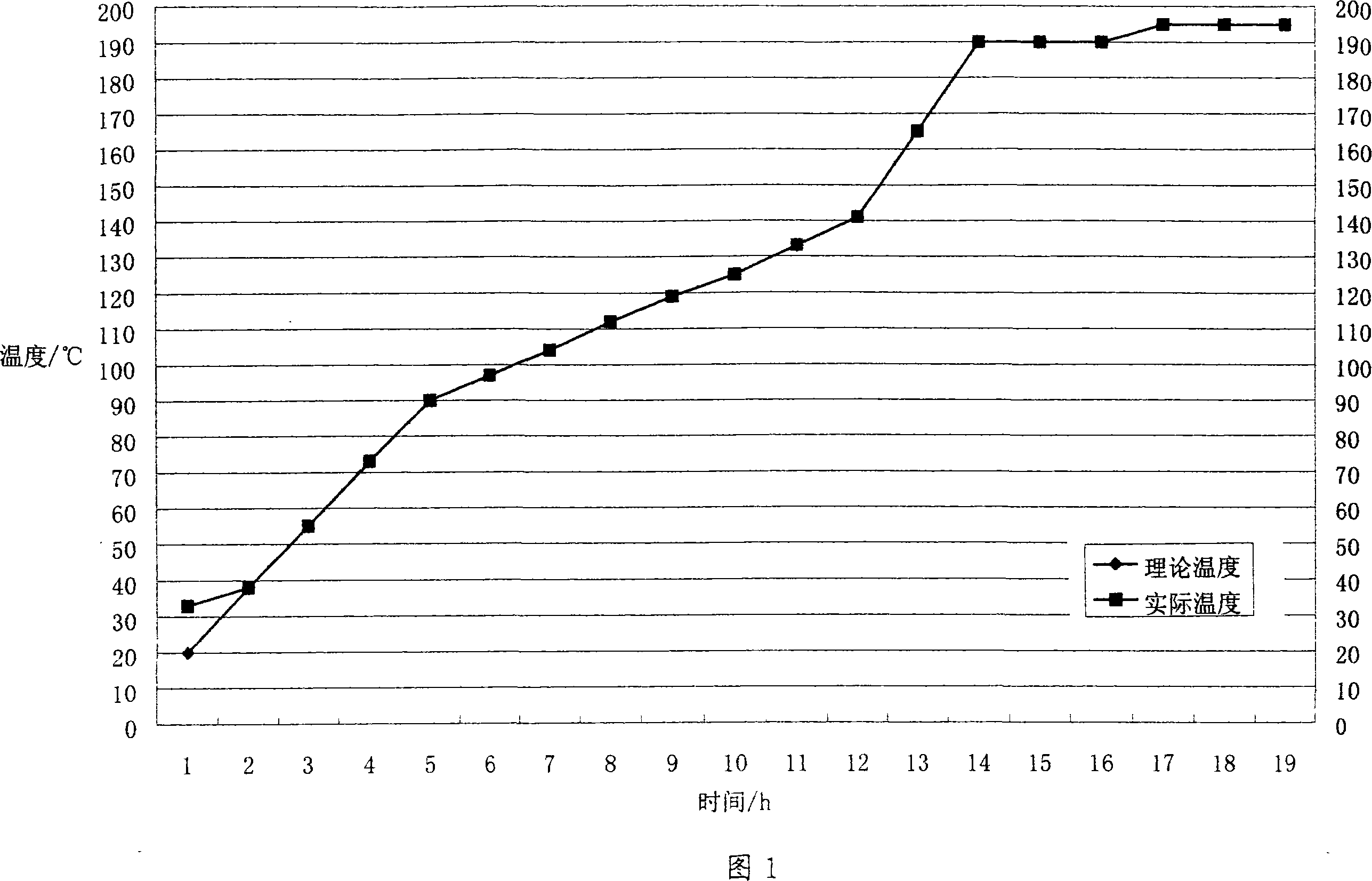

[0063] Its preparation process is the same as that of Example 1, and the hardening curve is shown in Figure 1.

[0064] Using this formula and process to produce a 355*4.0*25.4 double mesh reinforced resin cutting sheet, it can cut 60 rails made of PD3 by 1 knife, with a loss of 55mm, and the entire cutting process is normal.

example 3

[0066] Select the bonding mixed abrasive of the following ratio, and its ratio by weight percentage is:

[0067] 30# brown corundum abrasive 41%

[0068] 36# brown corundum abrasive 36.5%

[0069] Phenolic resin solution 5%

[0070] 240 mesh phenolic resin powder 10%

[0071] 120 mesh cryolite 5%

[0072] PTFE powder (average particle size 5μm) 2.5%

[0073] Its preparation process is the same as the above examples, and the hardening curve is shown in Figure 1.

[0074] Using this formula and process to produce a double mesh reinforced resin cutting sheet with a model size of 355*4.0*25.4, after cutting a 60 steel rail made of PD3, the loss is 25mm, and the entire cutting process is normal.

[0075] According to the above three examples, the comparison of the use effects of the three cutting sheets produced by the above three examples is shown in the following table 1:

[0076] Table 1 Comparison of the effects of three cases of cutting discs

[0077] example ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com