Method for preparing chromium-containing sludge ceramsite

A technology of chromium sludge and ceramsite, applied in the production of clay products, ceramic materials, other household appliances, etc., can solve the problems of difficult secondary pollution, small amount of slag, polluted land and groundwater, etc., and achieve low production costs. , The effect of eating a large amount of slag and thoroughly detoxifying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A method for preparing chromium-containing sludge ceramsite, comprising the following steps:

[0021] (1) Chromium-containing sludge is wet ground to 120 mesh; urban sludge, weathered rock, silt or kaolin is dried and dry ground to 100 mesh with reducing agent;

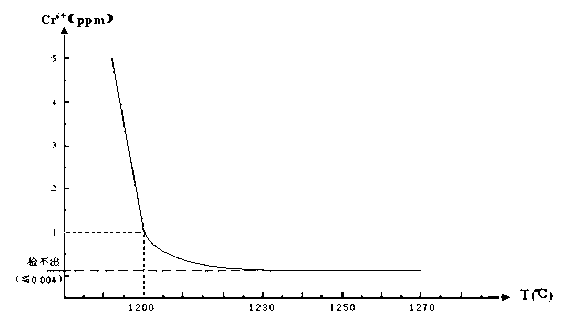

[0022] (2) Mix the materials in step (1) evenly, press them into strip-shaped particles with a diameter of 10mm and a length of 20mm, and after pelleting and drying, enter the rotary kiln for calcination at a high temperature of 1230°C for 45 minutes to obtain chromium-containing sludge Ceramsite; the discharged material can be sent to the finished product warehouse after cooling down.

[0023] The mass percentage of each component of the raw material is: 30% of chromium-containing sludge, 60% of urban sludge, weathered rock, silt or kaolin, and 10% of reducing agent.

[0024] The reducing agent is a raw material that produces reducing substances at high temperature.

Embodiment 2

[0026] A method for preparing chromium-containing sludge ceramsite, comprising the following steps:

[0027] (1) Chromium-containing sludge is wet ground to 120 mesh; urban sludge, weathered rock, silt or kaolin is dried and dry ground to 100 mesh with reducing agent;

[0028] (2) Mix the materials in step (1) evenly, and press them into strip-shaped particles with a diameter of 10mm and a length of 20mm. After forming into balls and drying, enter the rotary kiln for calcination at a high temperature of 1270°C for 45 minutes to obtain chrome clay ceramsite ; The output material can be sent to the finished product warehouse after cooling down.

[0029] The mass percentage of each component of the raw material is: 50% of chromium-containing sludge, 40% of urban sludge, weathered rock, silt or kaolin, and 10% of reducing agent.

[0030] The reducing agent is a raw material that produces reducing substances at high temperature.

Embodiment 3

[0032] A method for preparing chromium-containing sludge ceramsite, comprising the following steps:

[0033] (1) Chrome sludge and chromium slag are wet ground to 120 mesh; urban sludge, weathered rock, silt or kaolin are dried and dry ground to 100 mesh with reducing agent;

[0034] (2) Mix the materials in step (1) evenly, press them into strip-shaped particles with a diameter of 10mm and a length of 20mm, and after pelleting and drying, enter the rotary kiln for calcination at a high temperature of 1250°C for 45 minutes to obtain chromium-containing sludge Ceramsite; the discharged material can be sent to the finished product warehouse after cooling down.

[0035] The mass percentage of each component of the raw material is: 60% of chromium-containing sludge, 30% of urban sludge, weathered rock, silt or kaolin, and 10% of reducing agent.

[0036] The reducing agent is a raw material that produces reducing substances at high temperature.

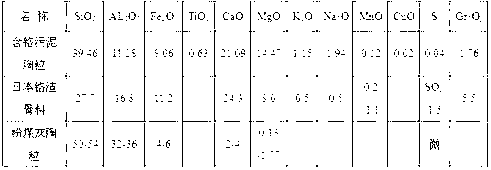

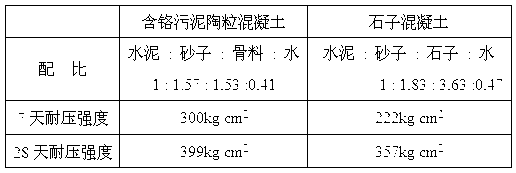

[0037] Table 1 Properties of chro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com