Method for preparing anode material of ferroferric oxide and carbon composite lithium battery

A technology of ferric tetroxide and negative electrode materials, which is applied in the direction of battery electrodes, circuits, electrical components, etc.

Inactive Publication Date: 2012-08-01

XINJIANG UNIVERSITY

View PDF5 Cites 21 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0010] But so far, there are no literature and patent reports to prepare composite materials of ferric oxide and carbon by high energy ball milling

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0029] Example 2

Embodiment 2

[0031] Example 3

Embodiment 3

[0033] Example 4

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

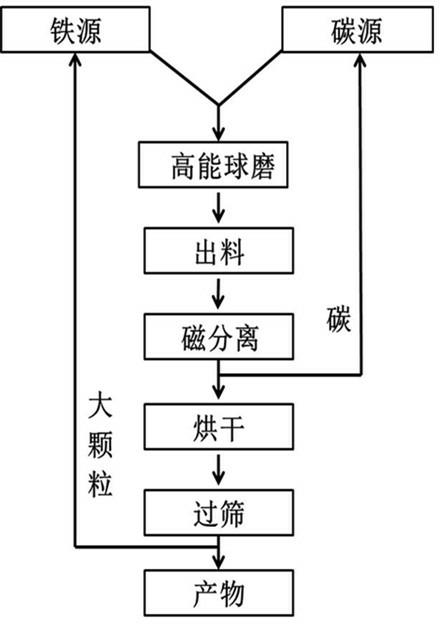

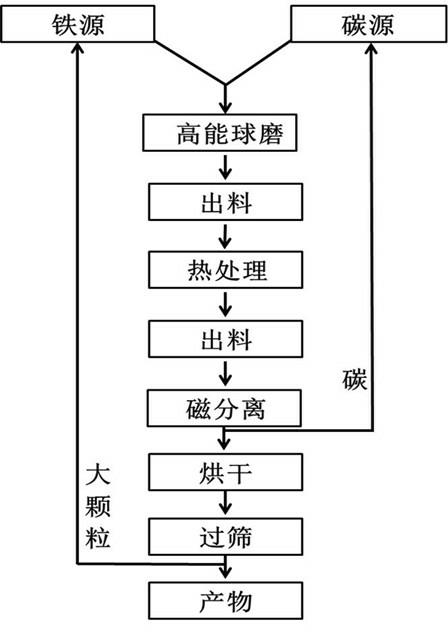

The invention relates to a method for preparing an anode material of a ferroferric oxide and carbon composite lithium battery. The method comprises the following steps of: weighing raw materials according to ferrum elements in a ferrum source and carbon elements in graphite; adding the weighed raw materials and a grinding ball into a ball grinding pot, adding a certain amount of distilled or deionized water into the ball grinding pot, and performing wet ball grinding or directly performing dry grinding; placing the ball grinding pot on a ball grinder, performing ball grinding for certain time at certain rotating speed, and discharging a product; when the ferrum source is hydroxide, chloride or various ferric salts, performing thermal treatment on the product subjected to ball grinding for several hours under the protection of inertia gas; performing magnetic separation on the product to separate out graphite particles which are not composited fully; and finally screening the graphite particles in sequence according to different apertures, drying the product subjected to wet grinding before screening, and screening to obtain the carbon-based ferroferric oxide composite material. The method has the characteristics of low cost, no pollution and simple process, and the material can be produced in a large scale.

Description

technical field [0001] The invention relates to a preparation method of a negative electrode material of a lithium battery, in particular to a preparation method of a negative electrode material of a ferric oxide-carbon composite lithium battery. Background technique [0002] As a new type of chemical power source, lithium-ion batteries have been widely used in various portable electronic devices due to their fast charging speed, long cycle life, good load performance, high energy density and working voltage, safety and no pollution. Production date grows. Lithium-ion battery anode materials, as an important factor to improve the energy and cycle life of lithium-ion secondary batteries, have been extensively studied worldwide. As anode materials for lithium-ion batteries, carbon-based materials have the advantages of high discharge capacity, long cycle life, and low cost. Therefore, as an economical and applicable raw material, most of the anode materials currently used i...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01M4/52H01M4/36

CPCY02E60/12Y02E60/10

Inventor 拜山·沙德克木提拉·阿曼吾布力卡斯木·喀迪尔谢木西丁·阿布拉

Owner XINJIANG UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com