Diamond dry grinding disc and manufacturing method thereof

A manufacturing method and diamond technology, which can be used in the manufacture of tools, abrasives, grinding devices, etc., can solve the problems of long grinding time, large processing and grinding volume, and rapid temperature rise, so as to improve processing quality and long grinding time. , the effect of improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

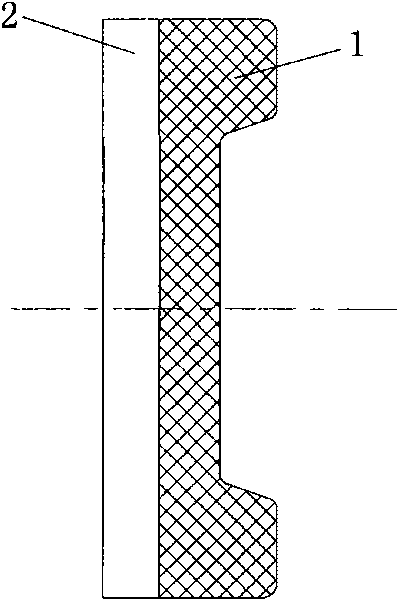

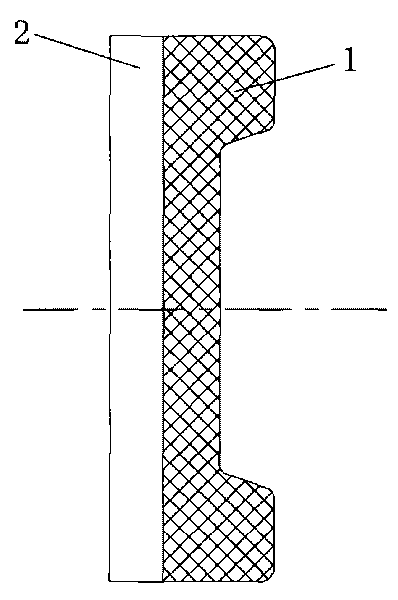

[0027] see figure 1 , The diamond dry grinding disc of the present invention is provided with an abrasive layer 1 and a connecting piece 2, the connecting piece 2 is bonded to the abrasive layer 1, and the connecting piece 2 is externally connected to a power transmission member. The thickness of the abrasive layer of the diamond dry grinding disc can be determined according to actual needs. Weigh 50g of high-temperature and oxygen-resistant resin, 20g of diamond particles, 20g of silicon carbide, and 10g of zinc oxide, and put them into a mixing tank to mix and stir evenly. Inject into a mold with a certain geometric shape, put in the nylon hook layer carrier accessories, close the mold and heat it to 100°C for 40 minutes, take it out and demould, and heat the molded abrasive layer in an oven for post-curing at a temperature of 120°C , time 4h, take out the cured abrasive layer and connect with heat-resistant polyurethane glue for bonding, so as to make a high-temperature re...

Embodiment 2

[0029] Similar to Example 1. Weigh 40g of high-temperature-resistant unsaturated polyester resin, 25g of diamond particles, 15g of tungsten carbide, 6g of aluminum powder, and 14g of aluminum oxide, put them into a mixing tank and mix them evenly, inject them into a mold with a certain geometric shape, and put them into a nylon hook layer carrier For accessories, heat the mold to 130°C for 20 minutes, remove the mold, put the formed abrasive layer into the oven to heat for post-curing, the temperature is 140°C, and take 1h, take out the cured abrasive layer and the connector with a durable Hot universal glue is used for bonding and bonding, so as to make high temperature resistant diamond dry grinding discs.

Embodiment 3

[0031] Similar to Example 1. Weigh 25g of high-temperature-resistant melamine resin, 15g of phenolic resin, 15g of diamond particles, 10g of boron nitride, 20g of silicon carbide, and 15g of titanium oxide, put them into a mixing tank and mix them evenly, inject them into a mold with a certain geometric shape, and put them into a nylon hook For layer carrier accessories, heat the mold to 120°C for 25 minutes, take out the mold, and put the formed abrasive layer into the oven for post-curing. The temperature is 130°C, and the time is 3h. Take out the cured abrasive layer and connecting parts Bonding and bonding with heat-resistant epoxy resin glue to make high-temperature resistant diamond dry grinding discs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com